You know, everyone’s talking about how the Internet of Things, or IoT, is changing things. It sounds fancy, but really, it’s just about making stuff work better. Think about your own life – how many times have you wished something was simpler or faster? Well, businesses are feeling that too. They’re looking for ways to do more with less, and that’s where IoT comes in. It’s not some futuristic dream; it’s here, and it’s helping companies get things done more smoothly. So, how does IoT improve efficiency? Let’s break it down.

Key Takeaways

- IoT helps businesses do more with less by making operations smoother and faster.

- Real-time data from IoT devices lets companies make smarter decisions quickly.

- Predictive maintenance uses IoT to fix equipment before it breaks, saving money and time.

- Automating tasks with smart devices frees up workers for more important jobs.

- IoT helps manage energy use and reduce waste, cutting down on costs and environmental impact.

Understanding How Does IoT Improve Efficiency

So, what does "efficiency" really mean for businesses today? It’s basically about getting the most out of what you have – your time, your money, your people, your materials – without wasting any of it. Think of it as doing more with less. In the past, we tried to boost efficiency by just working harder or cutting corners, but that only gets you so far. Now, with the Internet of Things (IoT), we have a whole new way to look at things.

Defining Business Efficiency in Modern Operations

Business efficiency is all about how well a company turns its resources into finished products or services. It’s a measure of how little waste is involved in that process. High efficiency means you’re not just saving money, but you’re also making sure your operations run smoothly and competitively. It’s not just about trimming costs; it’s about getting the best possible outcome from every input. This can involve a lot of different things, from making sure your supply chain is running like clockwork to automating simple, repetitive tasks that used to take up a lot of employee time.

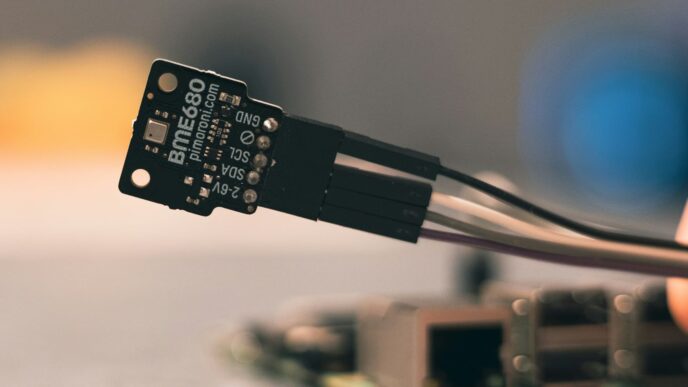

The Transformative Role of IoT in Business

IoT is changing the game. It’s a network of connected devices – think sensors, machines, even everyday objects – all talking to each other. In a business setting, this means creating systems where information flows freely and in real-time. This connectivity allows for a much smarter way of operating. For example, manufacturers can use IoT sensors to keep an eye on their machinery. These sensors can flag potential problems before they cause a breakdown, which is a huge win for reducing downtime and saving cash. It’s about having eyes and ears everywhere, all the time, giving you a constant stream of data to work with. This constant flow of information is key to making better choices and improving how things get done across the board. You can find out more about how IoT is transforming businesses by looking at real-time performance insights.

Achieving More With Less Through IoT

How does this "more with less" actually happen? Well, IoT helps by giving us real-time data. Imagine a logistics company tracking its delivery trucks. With IoT, they can see exactly where each truck is, how it’s performing, and even get alerts about traffic jams. This means they can reroute drivers on the fly, cutting down on fuel costs and getting packages delivered faster. Or think about agriculture: sensors in the field can tell farmers exactly when and how much to water their crops. This saves water and boosts the harvest. It’s about using technology to make smarter decisions, automate processes that used to require a lot of manual effort, and ultimately, get more done with the resources you already have.

Leveraging IoT for Enhanced Operational Performance

So, how does this whole "Internet of Things" thing actually make things run smoother in a business? It’s all about getting a much clearer picture of what’s happening, right when it’s happening. Think of it like having a bunch of tiny eyes and ears all over your operations, constantly feeding you information.

Real-Time Data Collection for Informed Decisions

Before IoT, figuring out what was going on often meant waiting for reports, digging through spreadsheets, or just going by gut feeling. Now, with connected devices, you get data as it’s generated. This means you’re not making decisions based on old news; you’re reacting to what’s happening now. This constant stream of information helps you spot problems before they get big, or notice opportunities you might have missed.

- Manufacturing: Sensors on machines can tell you their exact speed, temperature, and output. If something starts acting weird, you know immediately.

- Logistics: GPS trackers on trucks give you real-time locations, estimated arrival times, and even how the cargo is being handled.

- Retail: Smart shelves can report inventory levels, so you know exactly what’s running low without having to count every single item.

This immediate access to data is a game-changer for making smart, quick choices.

Streamlining Workflows Across Industries

IoT isn’t just about collecting data; it’s about using that data to make processes flow better. When different parts of your operation can talk to each other, things get a lot less clunky.

Imagine a warehouse. When a product is scanned out, an IoT system can automatically update inventory records, trigger a notification for restocking if needed, and even adjust climate control in the storage area if the item is sensitive. It removes manual steps and reduces the chance of errors.

In healthcare, connected devices can monitor patient vitals remotely. This data can be sent directly to a doctor’s dashboard, allowing them to check on multiple patients efficiently and intervene faster if a patient’s condition changes. It cuts down on the back-and-forth and makes sure care is delivered when it’s most needed.

Optimizing Resource Allocation and Time Management

Knowing exactly how your resources are being used is key to not wasting them. IoT gives you that visibility. You can see which machines are running most efficiently, which areas are using the most energy, or how much time is actually spent on certain tasks.

Let’s say you run a fleet of vehicles. By tracking their routes and usage patterns with IoT devices, you can identify the most efficient routes, schedule maintenance based on actual mileage rather than just a calendar, and even monitor driver behavior to promote safer, more fuel-efficient driving. This kind of detailed insight helps you use your vehicles, your staff’s time, and your budget much more effectively. It’s about getting the most out of what you have, without overspending or overworking your team.

Predictive Maintenance and Downtime Reduction with IoT

You know, the old way of fixing machines was basically waiting for them to break. Then you’d scramble to fix it, losing precious production time and probably paying extra for emergency parts. It was a real headache. But now, with IoT, things are changing.

Predicting Equipment Failures Before They Occur

IoT sensors are like tiny health monitors for your machinery. They’re constantly checking things like vibration levels, temperature, and how much power a machine is using. All this data gets sent off for analysis. The smart systems look for patterns that suggest something isn’t quite right, even if it’s just a small change. This means you can often spot a problem brewing long before it causes a major breakdown. Think of it like a doctor noticing a slight change in your heart rate and catching a potential issue early.

Minimizing Costly Emergency Repairs

When a machine breaks down unexpectedly, it’s not just the repair bill that hurts. You’ve got production lines grinding to a halt, missed deadlines, and unhappy customers. By predicting failures, maintenance can be scheduled for a time that works best, usually during planned downtime. This avoids those frantic, expensive emergency fixes. It’s way cheaper to replace a part during a scheduled maintenance window than to deal with a catastrophic failure that stops everything.

Extending Equipment Lifespan Through Proactive Care

Constantly running machines hard, especially when they’re starting to show signs of wear, can really shorten their life. Predictive maintenance allows for a more gentle approach. Instead of waiting for a part to fail completely, you can replace it when the data suggests it’s nearing the end of its useful life. This kind of proactive care means your equipment doesn’t get pushed past its limits unnecessarily. It’s like taking care of your car with regular oil changes and tune-ups – it just runs better for longer.

Automating Tasks and Boosting Productivity

Think about all the repetitive stuff that eats up your team’s day. You know, the kind of work that’s necessary but doesn’t exactly get the creative juices flowing. IoT is a total game-changer here. By hooking up devices and systems, we can get machines to handle a lot of these tasks on their own. This isn’t just about making things faster; it’s about freeing up your people to do more interesting and important work.

Reducing Labor Costs with Smart Devices

Let’s be real, labor costs are a big deal for any business. Smart devices, powered by IoT, can take over a lot of the grunt work. Imagine inventory management where sensors automatically track stock levels and even place reorders when things get low. No more manual counting or someone forgetting to order supplies. This kind of automation means you need fewer people dedicated to these routine jobs. It’s not about replacing people entirely, but about making sure everyone’s time is spent where it’s most effective. For example, in warehouses, robots can handle picking and packing, which speeds things up and cuts down on the need for a large manual workforce. This is a big part of why industrial automation is becoming so important.

Enhancing Accuracy in Repetitive Processes

Humans are great at a lot of things, but when it comes to super repetitive tasks, mistakes can happen. Machines, on the other hand, don’t get bored or tired. IoT-enabled systems can perform these tasks with incredible consistency. Think about quality control on an assembly line. Sensors can check every single product for defects far more reliably than a person could, day in and day out. This means fewer faulty products going out the door and less waste from errors. A study by Deloitte found that companies using automation often see a 20% jump in productivity because of this improved accuracy and speed.

Redirecting Workforce to Strategic Activities

So, what happens when machines start handling the routine stuff? Your employees get to focus on what humans do best: problem-solving, critical thinking, and innovation. Instead of spending hours on data entry or manual checks, your team can work on developing new strategies, improving customer relationships, or tackling complex challenges. This shift not only makes the work more engaging for your employees but also drives the business forward in more meaningful ways. It’s about using your human talent for high-impact activities, not just keeping the wheels turning. This is a key benefit that helps businesses achieve a faster return on investment.

Optimizing Energy Consumption and Minimizing Waste

It’s pretty wild how much energy and resources businesses can just… lose. Think about it – lights left on in empty rooms, machines running when they don’t need to, or even just processes that are inherently inefficient. IoT is changing that game.

Identifying Energy-Intensive Operations

First off, you can’t fix what you don’t know is broken, right? IoT sensors are like tiny detectives, constantly gathering data on where and how energy is being used. They can track everything from the power draw of individual machines to the overall consumption of a building. This isn’t just about looking at your monthly utility bill anymore; it’s about getting granular. You can see which pieces of equipment are energy hogs, when they’re using the most power, and if they’re operating efficiently. This kind of detailed insight helps pinpoint exactly where the waste is happening. For example, a manufacturing plant might discover that a specific set of machines uses significantly more power during off-peak hours than expected, suggesting a need for recalibration or a change in operating schedules. This real-time data collection is key to understanding your energy footprint. You can find out more about smart scheduling methodologies designed to reduce energy consumption.

Implementing Smart Energy Management Systems

Once you know where the energy is going, you can start managing it smarter. This is where smart energy management systems come in. These systems use the data collected by IoT devices to automate adjustments. Think of it like a thermostat for your entire operation. You can set parameters, and the system will automatically dim lights in unoccupied areas, power down idle equipment, or even shift energy-intensive tasks to times when electricity is cheaper. This automation takes the guesswork out of energy saving. It means you’re not relying on people remembering to flip switches or adjust settings. The system does it for you, consistently and efficiently. This proactive approach can lead to significant reductions in utility costs and a smaller environmental impact.

Reducing Waste Through Precise Process Control

Beyond just energy, IoT also helps cut down on material waste. By monitoring processes with sensors, businesses can achieve much tighter control. For instance, in manufacturing, sensors can ensure that the exact amount of raw material is used for each product, preventing overages. In agriculture, smart irrigation systems use soil moisture data to water crops only when and where needed, saving water. Even waste collection can be optimized; smart bins can signal when they’re full, so collection trucks only visit when necessary, reducing fuel consumption and emissions. This level of precision minimizes resources used and output discarded.

Here’s a quick look at how IoT can help:

- Energy Monitoring: Real-time tracking of electricity, gas, and water usage.

- Automated Adjustments: Systems that turn off lights or equipment when not in use.

- Leak Detection: Sensors that alert you to water or gas leaks immediately.

- Optimized Scheduling: Shifting operations to off-peak hours to save money.

- Resource Tracking: Ensuring precise use of raw materials in production.

Improving Asset Utilisation and Achieving Faster ROI

Think about all the equipment and tools your business uses. Are they all working as hard as they could be? Often, there’s a lot of potential sitting idle or not being used to its full capacity. That’s where IoT really shines.

Maximizing the Potential of Connected Assets

When you connect your assets – whether it’s a fleet of trucks, a production line, or even just a set of specialized tools – you get a clear picture of how they’re performing. Sensors can tell you if a machine is running too hot, if a vehicle is stuck in traffic, or if a piece of equipment is being used less than it should be. This kind of real-time information lets you make smart adjustments. For instance, if you see that a particular machine on your assembly line is consistently underperforming, you can investigate why. Maybe it needs a tune-up, or perhaps its workload needs to be shifted. By understanding exactly how your assets are being used, you can make sure they’re working for you, not against you.

Lowering Capital Expenditure Through Better Management

Because you have a better handle on your existing assets, you’re less likely to buy new ones you don’t actually need. If you know that your current fleet of delivery vans is being used efficiently and isn’t breaking down often (thanks to predictive maintenance, which we’ll talk about more later), you can put off buying new ones. This means less money tied up in new purchases. It’s about getting the most out of what you already own. This careful management can lead to significant savings on big-ticket items.

Recouping Investments Sooner Through Cost Savings

All these improvements – less downtime, better use of equipment, fewer unnecessary purchases, and optimized operations – add up. They directly translate into lower operating costs. When your costs go down, the money you spent on implementing IoT solutions starts to pay for itself much faster. It’s a direct path to a quicker return on investment (ROI). Instead of waiting years to see the financial benefits, you can start seeing them in months. This makes adopting new technology a much more attractive proposition for the bottom line.

The Scalability and Integration of IoT Solutions

So, you’ve got your IoT setup humming along, making things more efficient. But what happens when your business starts to grow? Or maybe you’ve got different systems that need to talk to each other? That’s where scalability and integration come into play, and honestly, it’s not as scary as it sounds.

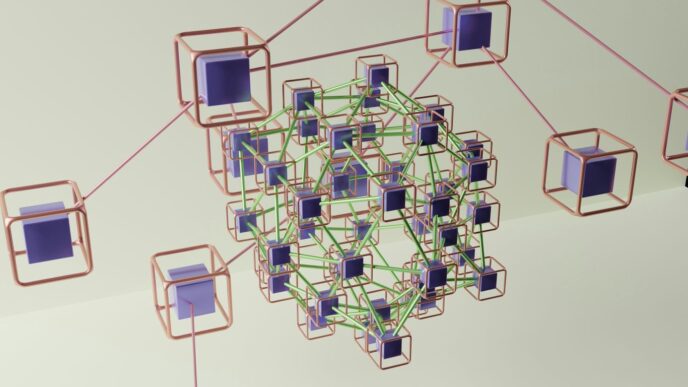

Scaling IoT Solutions for Growing Businesses

Think of it like adding more rooms to your house. You don’t just knock down walls and start over; you build onto what you have. IoT solutions are designed to do just that. They’re built with modularity in mind, meaning you can add new devices or applications as your needs change. This is super handy because you don’t have to replace your entire system every time you expand. Cloud-based platforms are a big part of this, giving you the processing power and storage you need without being stuck with a fixed setup. As your business takes on more operations or enters new markets, your IoT infrastructure can keep up. It’s all about making sure your tech grows with you, not against you.

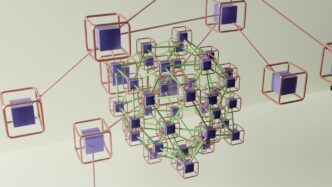

Seamless Integration of Diverse IoT Devices

Now, let’s talk about getting all your different gadgets and systems to play nice together. Integrating IoT into what you already have can feel like a puzzle. You’ve got to check if your current network can handle all the new data coming in and if your systems can actually process it. It’s not just about plugging things in; it’s about making sure everything communicates effectively. This often means looking at your network capacity and maybe even upgrading it. Plus, you’ve got to think about security – more devices mean more potential entry points for trouble. Working with folks who know their way around this stuff can really smooth out the process, helping you integrate IoT into existing legacy systems without a massive headache.

Managing and Routing API Requests Efficiently

When you have a lot of IoT devices, they’re constantly sending information back and forth. This is often done through something called APIs (Application Programming Interfaces). Think of APIs as the messengers that allow different software applications to talk to each other. With many devices, you get a lot of these messages, or requests. Managing them efficiently is key. You need systems in place that can handle this traffic without getting bogged down. This means making sure requests are routed to the right place quickly and that the system doesn’t get overloaded. It’s like directing traffic in a busy city – you need clear lanes and smart signals to keep things moving smoothly. Getting this right means your data flows properly, and your applications can actually use the information your devices are collecting.

The Takeaway: IoT Isn’t Just the Future, It’s Now

So, we’ve seen how the Internet of Things is really changing the game for efficiency. It’s not some far-off idea anymore; it’s here, and it’s making a big difference. From spotting problems before they happen with predictive maintenance to just making sure machines are running at their best, IoT gives us a level of insight we just didn’t have before. Companies are seeing real improvements, like less downtime and better use of resources, which all adds up. The technology is getting easier to use too, meaning more businesses can jump on board. If you’re looking to get more done with less and stay competitive, looking into IoT is definitely the way to go.

Frequently Asked Questions

What exactly is the Internet of Things (IoT) in a business setting?

Think of IoT as a network of smart devices that can talk to each other and share information. In business, it’s like giving your machines and tools a voice so they can tell you what they’re doing, helping you make smarter choices and get more done automatically.

How does IoT help businesses save money?

IoT helps save money in a few cool ways. It can predict when machines might break down so you can fix them before they cause big problems, saving on expensive emergency repairs. Plus, it helps you use resources like energy and materials more wisely, cutting down on waste and lowering your bills.

What are the main ways IoT makes businesses run better?

IoT really speeds things up by making processes smoother and automating boring, repetitive jobs. This means less waiting around, fewer mistakes, and getting more work done in less time. It’s all about working smarter, not just harder.

Can IoT help make customers happier?

Yes, it can! By understanding how customers use products or what they need in real-time, businesses can offer more personalized services and products. This makes customers feel more valued and satisfied.

Is it hard to set up and use IoT for a business?

Setting up IoT used to be tricky, but it’s gotten much easier. Many platforms now help you connect devices, manage data, and get insights without needing a huge team of tech experts. You can start small and grow as your business does.

What happens if a business uses too much energy? Can IoT help?

Absolutely! IoT devices can keep a close eye on how much energy different machines and processes are using. This helps businesses spot where energy is being wasted and make adjustments, like using less power during busy times, which cuts down on electricity costs and helps the environment.