Introduction

The hydraulic bursting strength test is a critical procedure in the world of material testing and quality assurance. This comprehensive guide will walk you through the nuances of this essential test, from what it is to how it works, and why it’s a cornerstone in ensuring product durability and safety.

Demystifying the Hydraulic Bursting Strength Test

What Is the Hydraulic Bursting Strength Test?

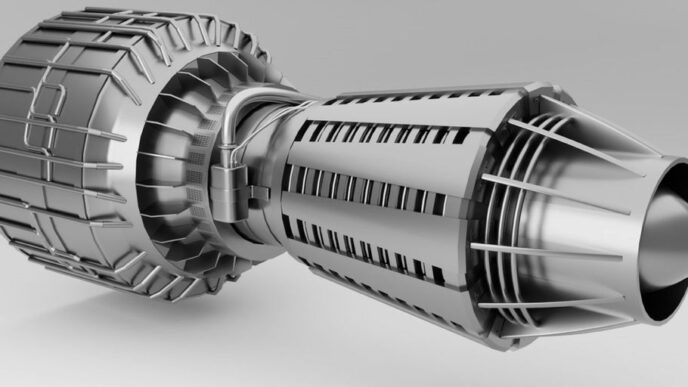

The hydraulic bursting strength test is a mechanical test used to determine the bursting strength of materials, typically paper, cardboard, and fabrics. It assesses how well a material can withstand an increasing hydraulic pressure before it ruptures.

The Test Setup

- Specimen Preparation: A small, circular specimen is clamped and sealed within the test apparatus.

- Hydraulic Pressure: Hydraulic fluid is introduced into the specimen at a controlled rate, creating internal pressure.

- Rupture Detection: Pressure continues to rise until the specimen ruptures, which is detected and recorded.

Precision Matters

High-precision instruments are crucial for accurate results. Advanced machines offer digital displays and automated controls, minimizing human error.

Significance of Hydraulic Bursting Strength Testing

Quality Assurance

Manufacturers rely on this test to ensure that materials used in products like packaging, textiles, and paper products meet industry standards.

Safety Compliance

In sectors like automotive and aerospace, hydraulic bursting strength tests are vital for certifying materials used in critical safety components.

Wide-Ranging Applications

Packaging Industry

- Cardboard Boxes: Ensuring the strength of cardboard used in packaging prevents damage to goods during shipping.

- Flexible Packaging: Materials for pouches and bags are tested to prevent leakage and ruptures.

Textile Industry

- Fabric Strength: Garment manufacturers assess fabric strength to ensure the longevity of clothing.

- Industrial Textiles: Materials used in industrial settings, like conveyor belts, are tested to ensure reliability.

Paper Industry

- Paper Quality: Print and writing papers undergo bursting strength tests to meet quality standards.

- Packaging Paper: Packaging paper is tested to guarantee its strength when used in various applications.

Advantages of Hydraulic Bursting Strength Testing

Precision and Consistency

Hydraulic bursting strength tests offer precise and consistent results, thanks to automated controls and digital recording.

Compliance and Quality

Ensuring that materials meet industry standards and customer expectations is crucial for product integrity.

Conclusion

The hydraulic bursting strength test is a cornerstone in the world of material testing and quality assurance. It plays a pivotal role in various industries, guaranteeing product durability, safety, and compliance with stringent standards.