The Building Blocks Of Everyday Materials Science

So, what exactly is materials science? It’s basically the study of all the stuff around us, from the phone in your hand to the chair you’re sitting on. It’s about understanding what things are made of, how they’re put together, and why they act the way they do. It’s the science behind why a glass window breaks but a rubber tire doesn’t.

Atomic Structures And Their Properties

Everything, and I mean everything, is made of atoms. These tiny particles are the fundamental units of matter. How these atoms arrange themselves and bond together dictates everything about a material. Think about it: the same atoms can form something as soft as graphite (pencil lead) or as hard as diamond. It all comes down to their structure.

- Arrangement Matters: Atoms can line up in neat, repeating patterns called crystals, or they can be jumbled up in a more disordered way.

- Bonding Types: Atoms can share electrons (covalent bonds), give and take electrons (ionic bonds), or have a sea of electrons floating around them (metallic bonds). Each type of bond gives materials different strengths and behaviors.

- Size and Shape: Even the size and shape of these atomic arrangements can change how a material behaves. Smaller, more organized structures often lead to different properties than larger, more random ones.

Crystallography In Common Objects

Crystallography is the science of crystals – those neat, repeating atomic arrangements. You might think crystals are just for fancy gemstones, but they’re everywhere. The salt you sprinkle on your food? That’s sodium chloride crystals. Sugar? Yep, crystals too. Even metals, which seem so uniform, are actually made up of tiny, interlocking crystals.

Here’s a look at how crystal structure affects common materials:

| Material | Crystal Structure Type | Key Property Influenced |

|---|---|---|

| Diamond | Cubic | Extreme hardness |

| Iron (at room temp) | Body-centered cubic | Strength, magnetism |

| Quartz (SiO₂) | Trigonal | Hardness, piezoelectricity |

| Table Salt (NaCl) | Face-centered cubic | Brittleness, solubility |

Understanding these crystal structures helps us predict how materials will perform. For instance, the way iron crystals are arranged changes when you heat it up, which is why blacksmiths can shape it.

Characterizing Material Behavior

So, how do scientists figure out all this stuff about atoms and crystals? They use a bunch of different tools and techniques to ‘characterize’ materials. It’s like giving a material a full physical exam to see what it’s made of and how it holds up under stress.

Some common ways we do this include:

- Microscopy: Looking at materials up close, sometimes with incredibly powerful microscopes, to see their structure, grain boundaries, and any defects.

- Spectroscopy: Shining light or other energy forms on a material and seeing how it interacts. This tells us what elements are present and how they’re bonded.

- Mechanical Testing: Bending, stretching, compressing, or hitting a material to see how strong it is, how much it can deform before breaking, and how tough it is.

- Thermal Analysis: Heating and cooling materials to see how their properties change with temperature, like when they melt or change phase.

By using these methods, we can get a really good picture of a material’s personality – its strengths, weaknesses, and how it’ll behave in different situations. It’s this detailed knowledge that lets us pick the right material for the job, whether it’s building a bridge or making a better frying pan.

Exploring Diverse Material Categories

Materials aren’t just one big blob of ‘stuff.’ They break down into different families, each with its own quirks and talents. Think of it like a toolbox – you wouldn’t use a hammer for every job, right? Same with materials. We’ve got polymers, ceramics, and metals, and they all do different things.

The World Of Polymers And Their Applications

Polymers are basically long chains of molecules. Plastics are the most common example, but they’re also in things like rubber, DNA, and even the proteins in your body. What’s cool about polymers is how we can tweak their structure to get different properties. Some are super flexible, like the plastic wrap you use for leftovers. Others are really tough and rigid, like the high-density polyethylene (HDPE) used in things from milk jugs to artificial joints. It’s wild to think that something as simple as a long chain of molecules can be so versatile. HDPE, for instance, isn’t just disposable plastic; it’s a backbone for modern life, showing up in infrastructure that lasts for ages and in systems designed for recycling.

Ceramics And Their Industrial Contributions

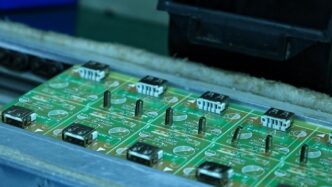

Ceramics are a bit different. They’re usually made from inorganic, non-metallic compounds, often fired at high temperatures. Think pottery, bricks, and even the spark plugs in your car. They’re known for being hard, brittle, and able to withstand really high heat. This makes them great for things like furnace linings or cutting tools. While they might seem old-fashioned, ceramics are still super important in lots of industries, from making tiles that can handle extreme conditions to components in electronics.

Metallurgy In Modern Engineering

Then there are metals. We’re all familiar with them – iron, aluminum, copper. Metallurgy is the science of working with metals. Metals are generally strong, conductive (both heat and electricity), and can be shaped. Steel, an alloy of iron and carbon, is everywhere, from buildings to cars. Aluminum is lighter and resists corrosion, making it popular for airplanes and cans. The way we combine metals to make alloys, like stainless steel or bronze, lets us fine-tune their properties even further, creating materials that are just right for specific jobs in engineering.

Advanced Frontiers In Materials Science

Materials science isn’t just about what we have now; it’s also about what’s coming next. We’re talking about materials that push the boundaries of what’s possible, opening up entirely new fields and applications. It’s pretty wild stuff.

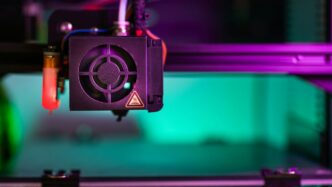

The Significance Of Thin Films And Surfaces

Think about the screens on your phone or the coatings on your glasses. These often rely on incredibly thin layers of material, sometimes just a few atoms thick. These aren’t just scaled-down versions of bulk materials; their properties can be totally different. Surface science looks at what happens right at the edge of a material, where it meets something else – air, liquid, or another solid. This interface is where a lot of action happens, like how a catalyst works or why metal rusts.

- Surface area matters: A huge surface area in a small volume means more interaction. Think of sponges, but at the atomic level.

- Quantum effects: When things get thin enough, quantum mechanics starts playing a bigger role, changing how electrons behave and thus the material’s properties.

- Coatings and protection: Thin films are used everywhere for protection, from anti-reflective coatings on lenses to corrosion resistance on bridges.

Nanomaterials And Their Potential

This is where things get really small – we’re talking about structures measured in nanometers (billionths of a meter). At this scale, materials can behave in ways we don’t see in larger pieces. For example, gold nanoparticles can appear red or purple, not gold, depending on their size and shape. This opens doors for all sorts of cool applications.

- Medicine: Nanoparticles can be designed to deliver drugs directly to specific cells, like cancer cells, minimizing side effects.

- Electronics: We’re seeing transistors that are only a few atoms thick, which could lead to much smaller and more powerful devices.

- Materials: Adding tiny amounts of nanomaterials can drastically change the strength or conductivity of a larger material.

Biomaterials For Health And Beyond

Biomaterials are designed to interact with biological systems. This isn’t just about implants like artificial hips, though that’s a big part of it. It also includes materials used in diagnostics, tissue engineering, and even drug delivery systems that work with your body. The goal is often to create materials that the body accepts without causing a negative reaction, or even materials that actively help the body heal.

| Material Type | Example Application | Interaction with Body |

|---|---|---|

| Polymers | Stents, sutures | Flexible, can degrade |

| Ceramics | Dental implants | Hard, inert |

| Metals | Hip replacements | Strong, can corrode |

Materials Science In Action

Materials science isn’t just for labs and textbooks; it’s happening all around us, shaping the way we live, work, and play. From the clothes we wear to the buildings we inhabit, the principles of materials science are constantly being put to work in some pretty amazing ways.

Polymers As The Backbone Of Modern Life

Think about it: plastics are everywhere. They’re in our packaging, our cars, our electronics, and even our medical devices. This isn’t by accident. Polymers, those long-chain molecules, offer an incredible range of properties that engineers can tweak. We’re talking about flexibility, strength, resistance to chemicals, and low cost. The ability to tailor polymers for specific jobs is what makes them so indispensable.

Here’s a quick look at why polymers are so useful:

- Versatility: From rigid pipes to stretchy films, polymers can be made to do almost anything.

- Lightweight: Compared to metals, polymers are much lighter, which is a big deal for transportation and portable electronics.

- Insulation: Many polymers are excellent electrical and thermal insulators, making them perfect for wiring and protective gear.

Metamaterials Transforming Buildings

Now, let’s talk about something a bit more futuristic, but already making waves: metamaterials. These aren’t your typical substances. They’re engineered materials with properties that don’t come from their composition alone, but from their carefully designed structure. Think of them as having properties dictated by their internal architecture, almost like a microscopic Lego set.

What does this mean for buildings? Metamaterials can be designed to control sound, light, and even heat in ways never before possible. Imagine walls that can block out all noise, or structures that can passively regulate temperature, reducing the need for heating and cooling. It’s a whole new way of thinking about construction, moving beyond just stacking bricks and mortar to actively engineering the environment within our buildings.

Smart Clothing And Interactive Textiles

Remember those sci-fi movies where clothes could change color or display information? Well, we’re getting closer. Smart textiles are fabrics woven with conductive threads, tiny sensors, or even micro-LEDs. These aren’t just for novelty; they have real applications.

Consider these possibilities:

- Health Monitoring: Wearable sensors integrated into clothing can track vital signs like heart rate and body temperature, sending data to your doctor or a health app.

- Performance Apparel: Athletes could benefit from clothing that adjusts its insulation based on body temperature or provides real-time feedback on their form.

- Interactive Interfaces: Imagine controlling your phone or smart home devices just by touching your sleeve. It’s all about making our clothing more functional and integrated with our digital lives.

The Science Behind Everyday Objects

You know, we use stuff all the time without really thinking about it. That plastic water bottle? The ceramic mug you’re drinking from? Even the metal spoon you stir your coffee with – they all have a story, a science behind why they work the way they do. It’s not just about what they look like, but what they’re made of and how that structure affects everything from how strong they are to how they feel in your hand.

Rethinking Plastics: Design and Durability

Plastic gets a bad rap, right? We see it as trash, something disposable. But honestly, some plastics are pretty amazing. Take High-Density Polyethylene (HDPE), for example. It looks pretty basic, maybe even cheap, but this stuff is tough. It’s used in everything from artificial joints in people to pipes that need to last for decades underground. It makes you wonder if the real issue isn’t plastic itself, but how we think about it and use it. It’s all about how it’s designed and how durable it turns out to be.

- HDPE’s strength makes it ideal for long-lasting infrastructure.

- It’s surprisingly resistant to chemicals and moisture.

- It can be designed for recycling, fitting into a circular economy.

The Hidden Physics of Single-Molecule Diagnostics

This one’s a bit more technical, but super cool. You might have heard about sensors that can detect diseases by finding just one molecule. For years, scientists thought the trick was all about making the electronics super sensitive. But recent research is showing something different. It turns out, it’s more about subtle chemical reactions and how molecules interact at surfaces. Tiny changes, like shifts in pH or how antibodies stick to a surface, can create a big enough electrical signal to be noticed. It’s less about super-powered electronics and more about clever chemistry and biology working together.

- Detecting a single molecule relies on more than just electronics.

- Chemical and biochemical amplification play a big role.

- These sensors are great at saying ‘yes, it’s there,’ but less so at saying ‘exactly how much is there.’

Understanding the Melting Process

Melting seems pretty straightforward, right? Ice turns into water, solid becomes liquid. Simple. But when you look at it on a tiny, atomic level, it gets way more interesting. Scientists have found there’s a weird in-between stage, a sort of ‘hexatic phase,’ that happens before a material fully becomes a liquid. It’s like it remembers it was a solid, but it can also flow. They’ve even seen this in 2D materials, and get this – some of these materials melt at much higher temperatures than you’d expect, like over 1200°C! It shows that even familiar processes like melting have hidden complexities.

- A hidden ‘hexatic’ phase exists between solid and liquid states.

- This phase retains some characteristics of the solid structure while flowing like a liquid.

- Melting points can be surprisingly high and vary significantly between 2D and 3D forms of the same material.

Sustainable Practices In Materials Science

It’s easy to get caught up in the shiny new materials and amazing applications, but we really need to talk about how we make and use stuff. Thinking about sustainability in materials science isn’t just a trend; it’s becoming a necessity. We’re talking about making choices now that won’t mess things up for people down the line.

The Role Of Sustainable Materials

So, what makes a material "sustainable"? It’s not just about being recyclable, though that’s a big part of it. It’s about the whole lifecycle. Where do the raw materials come from? How much energy and water does it take to make it? What happens when you’re done with it? Ideally, we want materials that have a low impact from start to finish. Think about using recycled plastics, like HDPE, not just for simple containers but for things that need to last, like pipes or even parts for artificial joints. Or consider bio-based materials that can be grown and then, at the end of their life, can break down naturally. It’s about finding alternatives that work just as well, if not better, than traditional options but without the heavy environmental cost.

Ethical Considerations In Material Development

Beyond the environmental side, there are ethical questions too. Who is mining the raw materials, and under what conditions? Are workers being treated fairly? Are communities being displaced? We also need to think about the long-term effects of new materials. For example, with nanomaterials, we’re still learning about their potential impact on health and the environment. It’s important to be upfront about what we know and what we don’t, and to proceed with caution. Transparency is key here. Companies need to be open about their supply chains and the testing they do.

Designing For A Circular Economy

This is where things get really interesting. Instead of the old "take-make-dispose" model, we’re aiming for a circular economy. This means designing products and materials so they can be used, reused, repaired, and then recycled back into the system, over and over. It’s like nature’s own cycles, but for our manufactured world. For instance, imagine designing electronics so that valuable metals can be easily recovered at the end of a device’s life, rather than being lost in a landfill. Or creating packaging that isn’t just single-use but can be refilled or composted. It requires a shift in thinking, from just making something functional to making something that can keep contributing value without creating waste. It’s a big challenge, but it’s the direction we need to go.

Wrapping Up Our Material World

So, we’ve looked at a bunch of stuff, right? From the plastic in your water bottle to the metal in your car, it’s all pretty amazing when you stop and think about it. These everyday items aren’t just random; they’re the result of a lot of science and smart design. Understanding even a little bit about how materials work can change how you see the world around you. It’s not just about knowing what things are made of, but appreciating the thought and effort that went into making them useful. Keep looking around, stay curious, and who knows what else you’ll discover about the stuff we use every single day.