Understanding The Asimo Robot Cost

Honda’s Ambitious Robotics Endeavor

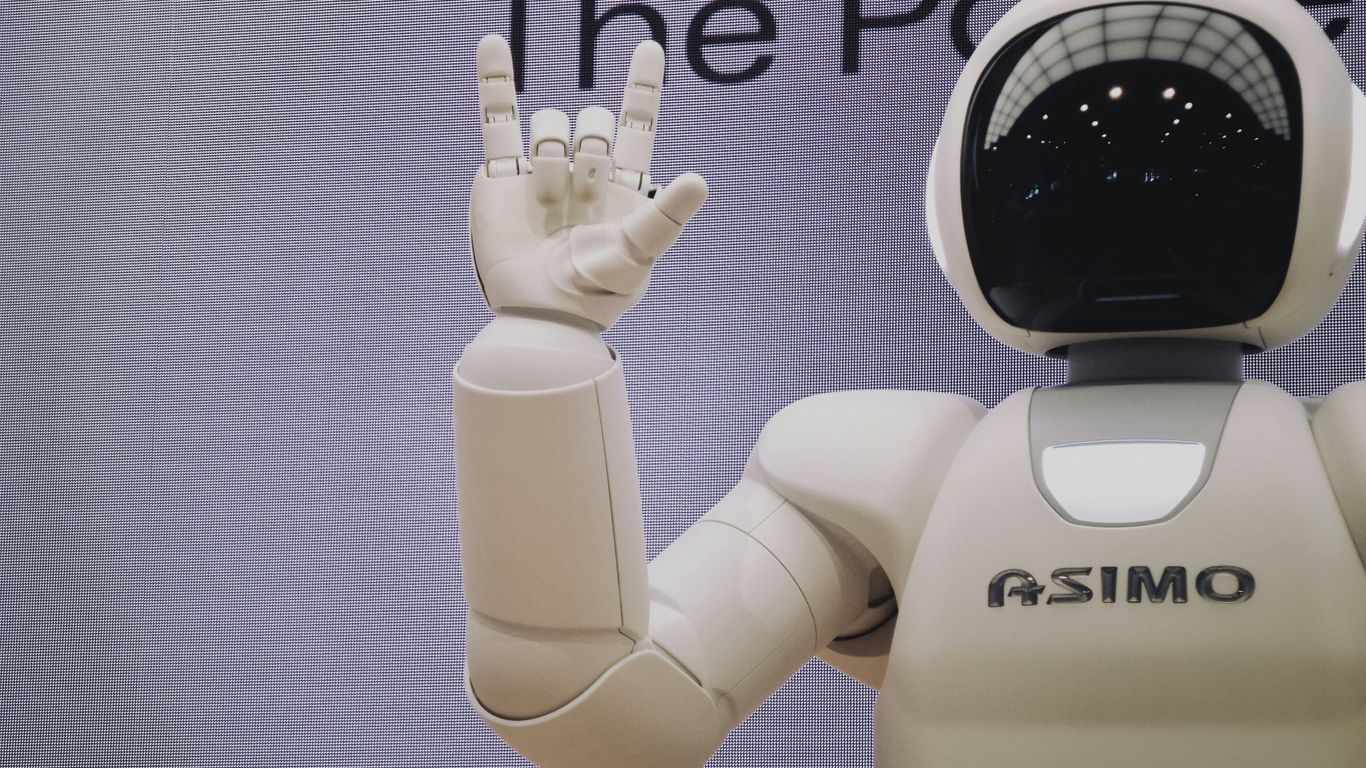

When Honda first rolled out ASIMO, it wasn’t just another gadget; it was the culmination of years, even decades, of serious work in robotics. Think about it – building a machine that could walk, interact, and do all sorts of things that humans do is incredibly tough. Honda poured a ton of resources into this, aiming to push the boundaries of what robots could achieve. This wasn’t about making a quick buck; it was about pioneering the future of human-like machines. It was a grand vision, and visions like that don’t come cheap.

The High Price of Cutting-Edge Technology

Let’s be real, when you’re working with technology that’s brand new, the costs are going to be sky-high. ASIMO was packed with some seriously advanced stuff for its time. We’re talking about sophisticated sensors, complex motors, and the software to make it all work together. Developing all of that from scratch, especially when you’re trying to make a robot move and react like a person, involves a lot of trial and error. Each little improvement, each new capability, meant more research, more testing, and more money spent. It’s like building a custom race car versus buying a standard sedan – the engineering and specialized parts add up fast.

ASIMO’s Role in Honda’s Broader Vision

ASIMO wasn’t just a standalone project; it was part of Honda’s bigger picture. They saw robots like ASIMO as a way to explore new technologies that could eventually find their way into other products, maybe even cars or assistive devices down the line. It was a way to learn and innovate. Think of it as a super-advanced research lab on legs. The investment in ASIMO helped Honda build up a wealth of knowledge in areas like artificial intelligence, control systems, and materials science. This knowledge is hard to put a price on, but the initial development certainly required a significant financial commitment to get there.

Factors Influencing ASIMO’s Price Tag

So, why did ASIMO end up costing so much? It wasn’t just one thing, but a whole bunch of really complex factors that added up. Think about it – Honda wasn’t just building a toy; they were trying to create a genuinely helpful robot that could interact with the real world.

Advanced Artificial Intelligence Development

Developing the ‘brain’ for a robot like ASIMO was a massive undertaking. We’re talking about creating systems that could understand speech, recognize faces and objects, and make decisions on the fly. This isn’t like programming a simple app; it involves years of research into machine learning, computer vision, and natural language processing. The sheer amount of computational power and the specialized knowledge needed to build and train these AI systems drove up costs significantly. It’s a bit like trying to teach a toddler everything about the world, but on a super-fast, super-complex scale.

Sophisticated Physical Dexterity and Awareness

ASIMO wasn’t just smart; it was also incredibly agile. It could walk, run, climb stairs, and even dance. Making a robot move like a human is ridiculously hard. It requires intricate joint designs, precise motor control, and sophisticated sensors to prevent it from falling over or bumping into things. Think about how many tiny adjustments your own body makes every second just to stay balanced – ASIMO needed to do something similar, but with metal and wires. The sensors alone, which allowed ASIMO to ‘see’ and ‘feel’ its surroundings, were cutting-edge and expensive.

Research and Development Investment

Honda poured a huge amount of money and time into ASIMO over decades. This wasn’t a quick project; it was a long-term vision. The costs include:

- Salaries for highly skilled engineers and researchers: These folks are at the top of their fields, and their expertise doesn’t come cheap.

- Prototyping and testing: Building multiple versions, breaking them, learning from mistakes, and rebuilding again is an expensive cycle.

- Materials and components: Using high-quality, specialized parts for a robot designed for advanced tasks adds up quickly.

It’s the kind of investment that pays off in knowledge and future technology, but it definitely has a hefty price tag upfront.

The Cost of Innovation in Humanoid Robotics

Building something as complex as a humanoid robot, especially one that aims to mimic human movement and interaction, isn’t cheap. It’s a massive undertaking that involves pushing the boundaries of what’s currently possible in engineering and artificial intelligence. Think about it: you’re not just assembling parts; you’re trying to create a machine that can walk, balance, manipulate objects, and maybe even understand what you’re saying. That level of sophistication comes with a hefty price tag.

Complex Engineering and Manufacturing

The sheer mechanical complexity of a humanoid robot is staggering. Each joint needs to be precise, strong, and agile. This requires advanced materials and manufacturing techniques that are far beyond what’s needed for simpler machines. We’re talking about custom-designed actuators, high-precision gears, and sophisticated sensor arrays all working together.

- Actuators: These are the ‘muscles’ of the robot, providing movement. Developing powerful yet energy-efficient actuators that can replicate the smooth motion of human limbs is a major engineering challenge.

- Sensors: To interact with the world, robots need eyes, ears, and a sense of touch. This means integrating cameras, microphones, lidar, and tactile sensors, all of which add to the cost and complexity.

- Materials: Lightweight yet durable materials are essential for mobility and safety. Using advanced composites or alloys can significantly increase the manufacturing cost.

The Pursuit of Human-Like Capabilities

Beyond just moving, the goal is often to make robots perform tasks that humans do. This means developing sophisticated software and AI to control that complex hardware.

- Balance and Locomotion: Getting a bipedal robot to walk smoothly, navigate stairs, or recover from a stumble is incredibly difficult. It requires advanced algorithms and constant fine-tuning.

- Dexterity: Replicating the fine motor skills of human hands, like picking up a delicate object without crushing it, is a huge hurdle. This involves intricate robotic hands and precise control systems.

- Perception and Decision-Making: For a robot to be truly useful, it needs to understand its environment and make decisions. This is where AI comes in, and developing AI that can handle the unpredictable nature of the real world is a massive research effort.

ASIMO’s Unique Design and Functionality

ASIMO, in its time, was at the forefront of this pursuit. Honda invested heavily in creating a robot that could interact with people in their environment, not just in a controlled factory setting. This meant focusing on features like:

- Smooth, Human-like Movement: ASIMO was designed to walk, run, and even dance, showcasing a level of agility rarely seen in robots of its era.

- Interaction Capabilities: It could recognize faces, understand voice commands, and even shake hands, requiring complex sensor integration and AI.

- Safety Features: Operating around humans meant incorporating safety measures to prevent accidents, adding another layer of engineering complexity and cost.

All these elements combined – the advanced mechanics, the sophisticated AI, and the specific design goals – contributed to the significant investment required to develop and build a robot like ASIMO.

ASIMO’s Legacy and Future Cost Implications

Pioneering Humanoid Robot Research

ASIMO was more than just a robot; it was a statement from Honda about what was possible in robotics. For years, ASIMO showed off incredible feats, like walking smoothly, climbing stairs, and even kicking a soccer ball. It had 34 motors working together, constantly checking its surroundings to move just right. This level of physical skill was groundbreaking for its time. While its artificial intelligence wasn’t quite ready for complex, unscripted tasks – sometimes it struggled to tell the difference between someone asking a question and someone taking a picture – its physical capabilities set a high bar. It really pushed the envelope for what we expected robots to be able to do physically.

Lessons Learned for Future Robot Development

Looking back at ASIMO, we can see a few key takeaways that still matter today. For one, the gap between impressive physical demos and true, adaptable intelligence is huge. Companies today still face this challenge. We see robots that can do amazing things in controlled settings, but ask them to handle a truly unexpected situation, and they might freeze up. Also, the cost of developing such advanced machines is immense. Honda poured a lot of resources into ASIMO over decades. This shows that building robots that can interact with our messy, unpredictable world isn’t cheap. It requires a long-term commitment to research and development.

The ASIMO Robot Cost as a Benchmark

When we talk about the cost of robots like ASIMO, it’s important to see it not just as a price tag, but as a benchmark for innovation. While ASIMO itself wasn’t really for sale to the public, its development cost was astronomical, reflecting the cutting-edge tech involved. Today, we see robots like Unitree’s G1 starting around $16,000 for research, while more advanced industrial models from companies like Agility Robotics can run upwards of $250,000. Even Tesla’s Optimus, aiming for mass production, is projected to be in the $20K-$30K range, but that’s still a significant investment. ASIMO’s journey highlights that the price of advanced humanoid robots is directly tied to the complexity of their design, the sophistication of their movement, and the sheer amount of research needed to get them there. It’s a reminder that true progress in robotics comes with a substantial, but often justifiable, cost.

Comparing ASIMO’s Cost to Other Robots

When we look at ASIMO’s price tag, it’s helpful to see how it stacks up against other robots, both past and present. For a long time, advanced humanoid robots were pretty much in a league of their own, costing hundreds of thousands, sometimes even millions, of dollars. ASIMO, with its development spanning years and significant investment, definitely fell into that high-end category. It was a marvel of engineering, but not exactly something you’d find at your local electronics store.

The Price of Advanced Humanoid Robots

For a while, if you wanted a robot that could walk, interact, and perform complex tasks, you were looking at a massive investment. Think about robots designed for research or very specific industrial applications. These machines required incredibly precise engineering, custom parts, and a whole lot of specialized software. It wasn’t uncommon for these to cost anywhere from $200,000 to $500,000, and sometimes even more, depending on the capabilities.

ASIMO’s Position in the Robotics Market

ASIMO was never really meant for mass market sales. Honda positioned it more as a symbol of their technological prowess and a platform for research and development. It was a showcase of what was possible. While other companies were developing robots for more practical, albeit still expensive, industrial uses, ASIMO was often seen demonstrating its ability to walk, run, and even interact with people in a more general, human-like way. This focus on advanced, general-purpose humanoid capabilities, rather than a specific task like lifting boxes, contributed to its high development and, by extension, its implied cost.

Technological Advancements Driving Costs

Several things made robots like ASIMO, and many of today’s advanced humanoids, so expensive:

- Complex Movement: Getting a robot to walk smoothly on two legs, maintain balance, and navigate uneven surfaces is incredibly difficult. This requires sophisticated sensors, powerful motors, and complex control systems.

- AI and Sensing: Integrating advanced artificial intelligence for decision-making and perception, along with sensors to understand the environment, adds significant cost. ASIMO had to ‘see’ and ‘understand’ its surroundings.

- Research and Development: The sheer amount of time, money, and brainpower that goes into designing, building, and testing these machines is immense. Years of research are packed into every joint and circuit.

It’s interesting to see how the market has changed. While ASIMO represented a significant investment in its time, newer robots are starting to hit the market with much lower price points, sometimes under $10,000 for research models, and projected costs for consumer versions aiming for the $20,000-$30,000 range. This shift is largely due to advancements in manufacturing, more efficient AI, and a growing number of companies competing in the space. Still, ASIMO’s cost was a reflection of its pioneering status in a very challenging field.

So, What’s the Takeaway on ASIMO’s Price Tag?

Looking back at ASIMO, it’s clear Honda poured a ton of resources into creating this groundbreaking robot. It wasn’t just about building a cool machine; it was about pushing the limits of what robots could do, especially in terms of movement and interaction. While ASIMO might not have become the household helper some imagined, the technology and lessons learned from its development definitely paved the way for future innovations. Think of it as a really expensive, but incredibly important, stepping stone. Honda’s continued exploration into robotics and other advanced tech shows they’re still committed to that forward-thinking approach, even if ASIMO itself was a product of its time and a significant investment.