The Core Components: What Robots Are Made Of

So, what exactly goes into making a robot tick? It’s not just a bunch of wires and metal, though those are part of it. Think of a robot like a tiny, automated creature. It needs a body, a brain, senses, and muscles to move around and do things. These basic parts work together to make a robot function.

Understanding the Basic Robot Structure

At its heart, a robot is usually built around a central processing unit, often called a "brain" or "brick." This is where the instructions are stored and processed. Attached to this brain are the robot’s "senses" – sensors – and its "muscles" – actuators. The structure itself can vary wildly, from simple wheeled platforms to complex, multi-limbed machines. The materials used also play a big role, affecting durability and weight.

The Role of the Programmable Brick

The programmable brick, or microcontroller, is the command center. It’s a small computer that runs the robot’s code. This is what tells the robot what to do, when to do it, and how to react to its surroundings. For example, a brick might receive information from a light sensor and then tell a motor to turn on based on that input. Different bricks have different capabilities, like how many sensors they can handle or how complex the programming can be.

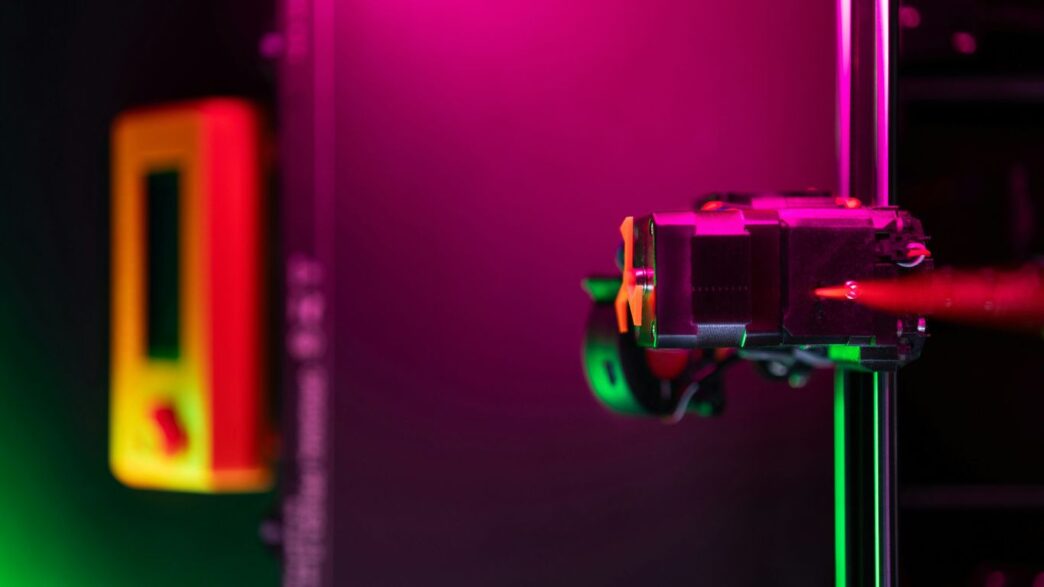

Sensors and Actuators: The Robot’s Senses and Muscles

Sensors are how robots perceive the world. They can detect things like light, sound, distance, temperature, or even touch. Think of a light sensor like a robot’s eye for brightness, or a touch sensor like its skin. Actuators are what allow robots to act on the world. These are typically motors that make wheels turn, arms move, or grippers grab things. Without sensors, a robot wouldn’t know what’s happening around it, and without actuators, it couldn’t do anything about it.

Building Blocks of Robotics: From Kits to Custom Builds

So, you want to build a robot, huh? That’s awesome! The cool thing is, you don’t have to be a rocket scientist to get started. There’s a whole world of robot kits and components out there, making it easier than ever to jump in. Whether you’re just curious or you’ve got a specific project in mind, there’s a way to build it.

Modular Robotic Systems

Think of modular systems like LEGOs for robots. You’ve got these individual blocks, each with a specific job – maybe one senses light, another spins a wheel, and another is the ‘brain’. You just snap them together, and poof, you’ve got a robot. This approach is super flexible because you can swap out parts or add new ones easily. It’s great for experimenting and learning how different functions work together. Cubelets are a good example of this, where magnetic cubes connect and each has a unique function. You can start simple, or get more advanced by using a Bluetooth block to tweak how they behave.

Integrated Robotic Kits

These kits are more like pre-packaged sets. You get everything you need in one box to build a specific type of robot. Sometimes they come mostly assembled, like the Smart Cutebot, which already has sensors and lights built-in and just needs a microcontroller like the BBC micro:bit to get going. Other times, like with the LEGO MINDSTORMS EV3 or SPIKE Prime, you’ll do a bit more building yourself. These kits often come with their own software to program the robot, which can be really helpful when you’re starting out. They’re designed to work together, so you don’t have to worry too much about compatibility.

Here’s a quick look at some popular kits:

| Kit Name | Age Range (Typical) | Programming Method | Key Features |

|---|---|---|---|

| LEGO MINDSTORMS | 10+ | Visual/Text-based Software | Motors, sensors, programmable brick, lots of bricks |

| LEGO WeDo 2.0 | 7+ | Visual Software (Tablet) | Simpler builds, motors, sensors, Bluetooth |

| Sphero RVR | 10+ | App/SDK (Python, JS) | All-terrain, sensors, programmable, expandable |

| Botley 2.0 | 5+ | Screen-free (button input) | Light sensors, 45-degree turns, memory |

| Cubetto | 3+ | Screen-free (tile board) | Wooden robot, simple navigation, story-based |

Customizable Robot Components

If kits feel too restrictive, or you’ve outgrown them, you can always go the custom route. This is where you pick and choose individual parts. You might start with a microcontroller, like an Arduino or a Raspberry Pi, which is like the robot’s brain. Then you add motors for movement, sensors to detect things, and a power source. This path takes more planning and technical know-how, but it gives you total control. You can even use components that are designed to work with other systems, like the Sphero RVR which can connect to a micro:bit or Arduino. It’s all about building exactly what you envision.

Powering the Machine: Energy Sources in Robots

Robots need power to do anything, just like us. Think about it – without energy, even the most complex machine is just a pile of parts. For most robots, especially the ones we build and play with, this power usually comes from a few main places. It’s not usually a tiny hamster wheel, though that would be pretty funny to see.

Rechargeable Battery Systems

This is probably the most common way to power up a robot. Rechargeable batteries are great because you can use them over and over. They’re like the energy packs for your robot. You plug them in, they fill up with juice, and then your robot can run around for a while.

- Lithium-ion (Li-ion): These are super popular because they hold a lot of energy for their size and weight. You find them in a lot of modern gadgets, and robots are no exception. They tend to last a good long time between charges.

- Nickel-Metal Hydride (NiMH): A bit older, but still used. They’re generally safer than some other types and don’t have as much of a "memory effect" where they lose capacity if you don’t fully discharge them.

- Lead-Acid: These are heavier and bulkier, often found in bigger robots or those that need a lot of power for a short burst. Think of the battery in a car – that’s lead-acid.

Wired Power Connections

Sometimes, a robot doesn’t need to move around freely. In these cases, plugging it directly into a wall outlet is the simplest way to keep it running. This means you don’t have to worry about batteries dying mid-task. It’s like plugging in your laptop to keep working; no interruptions.

- Constant Power: Great for robots that perform a single, stationary task, like a robotic arm on an assembly line.

- No Battery Management: You don’t need to track charge levels or swap batteries.

- Limited Mobility: The robot is tethered, so it can only operate within the reach of its power cord.

Power Management for Autonomous Operation

When a robot has to run on its own for a while, like a rover exploring Mars or a cleaning bot in your house, managing its power is a big deal. It’s not just about having a battery; it’s about using that energy wisely. Smart power management helps robots last longer and perform their tasks without needing constant supervision. This involves things like:

- Low-Power Modes: When the robot isn’t actively doing something, it can go into a sleep mode to save energy.

- Efficient Components: Using motors and processors that don’t suck up too much power in the first place.

- Task Scheduling: Planning out when to do energy-intensive tasks so they don’t all happen at once.

- Recharging Strategies: For mobile robots, this might mean finding a charging station when the battery gets low.

The Brains of the Operation: Processing and Control

So, how does a robot actually do things? It’s not magic, it’s all about the "brains" – the processing and control systems. Think of it like your own brain telling your hand to pick something up. For robots, this means a few key parts working together.

Microcontrollers and Their Functions

At the heart of most robots, especially the ones you might build yourself, is a microcontroller. This is basically a tiny computer on a single chip. It’s programmed to take in information from sensors and then tell the motors or other parts what to do. It’s like the robot’s central nervous system. Some are super simple, designed for basic tasks like moving forward or backward, while others are much more powerful, capable of complex calculations and decision-making. For example, a simple robot might use a microcontroller to just follow a line, whereas a more advanced one could use it to navigate a maze or even recognize objects.

Connectivity Options: Bluetooth and USB

How do we talk to the robot’s brain? That’s where connectivity comes in. Most modern robots use either USB or Bluetooth. USB is great for a direct, wired connection, usually for initial programming or when you need a really stable link. It’s like plugging your computer directly into the internet. Bluetooth, on the other hand, offers wireless freedom. This means you can control your robot from a phone, tablet, or computer without being physically tethered to it. This is super handy for making robots that move around or for controlling them from a distance. Some robots, like the Blue-Bot, use Bluetooth to connect to a special app, which lets you program more complex movements, like turns and loops, right from your device.

Software and Programming Languages

Finally, none of this works without software. The microcontroller needs instructions, and that’s what programming languages provide. For beginners, there are often visual block-based languages, similar to Scratch. These let you drag and drop commands to build your robot’s behavior. It’s a really intuitive way to start. As you get more comfortable, you can move on to text-based languages like Python or JavaScript. These offer more power and flexibility. For instance, the Artie 3000 robot lets you use different languages to draw designs, showing how varied the programming options can be. The choice of software and language really depends on the robot’s complexity and what you want it to achieve.

Materials and Construction: The Physical Form of Robots

So, what’s actually holding these robotic wonders together? It’s not just about fancy circuits and code; the physical stuff matters a lot. Think about it – a robot needs to be tough enough to handle whatever task you throw at it, whether that’s zipping around the living room or carefully picking up tiny objects.

Durable ABS and Quality Materials

Most robot kits and components you’ll find are made from ABS plastic. It’s a pretty common material because it’s strong, can take a beating, and is relatively inexpensive. You know, the same stuff LEGO bricks are made of? That’s a good sign for durability. When you’re putting a robot together, especially if it’s a kit you build yourself, you want parts that fit well and don’t feel flimsy. Good quality materials mean your robot is less likely to fall apart after a few bumps or tumbles. Some higher-end or specialized robots might use metal parts for critical joints or structural elements to add even more strength, but for most hobbyist robots, ABS is the go-to.

Design Considerations for Movement

How a robot moves is a big part of its design. You’ve got wheels, tracks, legs, and even arms. The shape and size of these parts, along with how they connect to the main body, really affect how the robot can get around. For example, a robot with large wheels can probably handle rougher surfaces better than one with small wheels. And if it has legs, the way those legs are designed and articulated will determine if it can climb stairs or just shuffle along flat ground. It’s all about making sure the physical form supports the intended function.

Assembly and Durability of Parts

Putting a robot together can be a project in itself. Many kits come with numbered bags of parts, which is a lifesaver. Imagine trying to sort through hundreds of tiny pieces without any organization – no thanks! Clear instructions are also key. You want parts that snap together securely or screw in easily without stripping.

Here’s a quick look at what you might find in a typical build:

- Main Body/Chassis: This is the core structure that holds everything else. It needs to be sturdy.

- Motors and Gears: These are what make the robot move. They need to be well-protected and securely mounted.

- Wheels/Tracks/Legs: The locomotion components. Their design impacts speed, maneuverability, and terrain capability.

- Sensors: These need to be positioned correctly to get accurate readings from the environment.

- Connectors and Cables: Keeping these tidy and secure is important so they don’t get snagged or disconnected during operation.

Ultimately, the goal is a robot that not only looks cool but also works reliably, and that comes down to the materials used and how well it’s put together.

Interactive Elements: How Robots Perceive and Interact

So, how does a robot actually know what’s going on around it, and how does it let us know what it’s doing? It’s all about its senses and its ways of showing us things. Think of it like us – we see, hear, and feel, and then we talk, move, or make faces to show how we feel or what we want.

Sensory Input: Light, Sound, and Motion

Robots have their own versions of senses, usually through different kinds of sensors. These are like their eyes, ears, and touch. For example, some robots have light sensors that can tell if it’s bright or dark, or even detect colors. Others have sound sensors, which might pick up on loud noises or specific tones. Then there are motion sensors, which can detect if something is moving nearby or if the robot itself has been bumped. Some advanced robots even have distance sensors, letting them know how far away objects are, which is super helpful for not bumping into walls.

Here’s a quick look at common sensors:

- Light Sensors: Detect brightness levels or specific colors.

- Sound Sensors: Pick up on noise levels or specific frequencies.

- Motion Sensors: Register movement in their vicinity.

- Distance Sensors: Measure how far away objects are.

- Touch Sensors: React when something makes contact.

Output Mechanisms: Lights, Speakers, and Movement

Once a robot processes information from its sensors, it needs a way to respond or communicate. This is where output mechanisms come in. They’re how the robot ‘talks’ back to us or interacts with its environment. Many robots have simple LED lights that can change color or blink to show status – maybe green means ‘all good’ and red means ‘uh oh’. Some can play sounds or even short voice messages through a small speaker. And of course, there’s movement itself – wheels turning, arms moving, or the whole body shifting. These actions are direct outputs based on the robot’s programming and sensor input.

User Interaction Through Apps and Remotes

Beyond just reacting to its surroundings, robots are often designed to be controlled or interacted with by people. This is frequently done through dedicated apps on tablets or smartphones, or sometimes with simple remote controls. These interfaces allow us to send commands, set up programs, or even drive the robot around like a remote-controlled car. For instance, you might use an app to tell a robot to follow a line, avoid obstacles, or perform a specific sequence of movements. This two-way communication between human and machine is what makes robotics so engaging and useful. It bridges the gap between the robot’s programmed logic and our own intentions.

So, What’s Next?

We’ve looked at a bunch of different robots, from the ones you build yourself to the ones that just roll around. It’s pretty wild how many different parts go into making these machines do their thing. Whether it’s a complex arm in a factory or a little bot that follows a line, it all comes down to sensors, motors, and some clever programming. It’s not just about the fancy stuff; it’s the basic building blocks that make it all work. Keep an eye out, because the world of robots is always changing, and who knows what cool new parts we’ll see next!