Foundations of Modern Autonomous Vehicle Hardware

Building self-driving cars isn’t just about writing clever code. The hardware underneath it all is a whole other beast, and getting it right is super important. Think of it like building a house – you need a solid foundation before you can even think about painting the walls.

Core Principles Guiding Hardware Design

When folks design the hardware for these complex machines, a few big ideas tend to pop up again and again. It’s not just about slapping the latest tech onto a car; there’s a lot of thought going into how everything fits together and works reliably.

- Bridging the Simulation-to-Real Gap: A huge challenge is making sure what works in a computer simulation actually works when you put it on a real car. Algorithms trained in a perfect virtual world often stumble when faced with the messy, unpredictable real world. Hardware needs to be designed to help close this gap, making the transition smoother.

- Open-Source and Accessibility: For a long time, only big companies with deep pockets could really mess around with this stuff. Now, there’s a big push towards open-source hardware and software. This means more people, like university researchers or smaller startups, can get their hands on the tech, tinker with it, and contribute their own ideas. It’s like sharing recipes so everyone can cook better meals.

- Modularity and Flexibility: Nobody wants a system that’s impossible to change or upgrade. Modern hardware is often designed in modules. This means you can swap out a sensor, upgrade a processing unit, or change a part of the vehicle’s mechanics without having to rebuild the whole thing from scratch. It makes development and testing way more adaptable.

Bridging the Simulation-to-Real Gap

This is a really big deal. You can run millions of miles in a simulator, but the real world throws curveballs that are hard to perfectly replicate. Things like weird lighting, unexpected road conditions, or even just the slight differences in how a sensor behaves can trip up an algorithm that looked perfect on screen.

- Realistic Sensor Modeling: The hardware in the simulator needs to mimic real sensors as closely as possible. This includes how they see, their limitations, and the kind of noise they produce. If the simulator’s camera model doesn’t account for glare, the car might not know what to do when it hits a patch of sun.

- Accurate Physics Engines: The way a car handles, brakes, and accelerates in the simulation needs to match reality. This involves complex physics calculations for things like suspension, tire grip, and weight distribution. A car that handles too perfectly in simulation might be a handful on a bumpy road.

- Actuator Fidelity: The simulated controls – steering, throttle, brakes – need to respond like their real-world counterparts. If the simulated brakes are too sensitive, the car might slam on the brakes too hard in a test, which isn’t helpful for training a smooth driving algorithm.

The Open-Source Revolution in Vehicle Prototyping

Remember when software was all locked up and you had to pay a fortune for every little thing? Well, that’s changing, and it’s happening in hardware too. Open-source hardware means the designs, schematics, and even the manufacturing instructions are shared freely. This has a massive impact on how quickly new ideas can spread and be tested.

- Lowering Barriers to Entry: Instead of spending hundreds of thousands on a custom test vehicle, researchers can often build or buy scaled-down versions based on open designs for a fraction of the cost. This democratizes research, allowing more minds to tackle the problems.

- Accelerated Innovation: When everyone shares their improvements, the whole field moves faster. Someone might find a better way to mount a sensor, or a more efficient way to wire up the processing unit, and that knowledge gets shared, benefiting everyone.

- Community Collaboration: Open-source projects thrive on community input. Developers can report bugs, suggest features, and even contribute code or hardware modifications. This collaborative spirit is vital for tackling the complex challenges of autonomous driving.

| Platform Type | Typical Scale | Key Advantage |

|---|---|---|

| Scaled Vehicle | 1:10 to 1:14 | Cost-effective prototyping, safer testing |

| Full-Size Vehicle | 1:1 | Real-world performance validation |

| Simulation | N/A | Mass testing of algorithms, edge cases |

These foundational principles are what allow us to move from theoretical concepts to tangible, testable systems, paving the way for safer and more capable autonomous vehicles.

Key Processing Units Powering Autonomous Vehicles

So, what actually makes an autonomous car think? It’s all about the brains, and in this case, that means some pretty specialized computer hardware. We’re not just talking about your average laptop here; these are systems built for speed and making split-second decisions.

Role of Embedded Computers and Controllers

At the heart of it all are embedded computers and controllers. Think of these as the dedicated workhorses. They’re built right into the vehicle, handling a ton of tasks that keep everything running smoothly. This includes managing power, communicating with different sensors, and even controlling basic functions like steering and braking when the main AI systems tell them to. They’re designed to be super reliable and efficient, because you really don’t want your car’s computer to crash when you’re trying to get somewhere.

GPU and AI Accelerators for Real-Time Processing

Now, for the heavy lifting – the actual decision-making part. This is where Graphics Processing Units (GPUs) and other AI accelerators come into play. These chips are amazing at crunching massive amounts of data simultaneously. When a car is driving, it’s getting information from cameras, lidar, radar, and more, all at once. GPUs can process all this visual and sensor data incredibly fast, which is exactly what you need to identify pedestrians, other cars, traffic lights, and figure out the best path forward. Without them, the car would be too slow to react to anything happening in real-time.

Centralized Versus Distributed Processing Architectures

How all this processing power is organized is also a big deal. You’ve got two main ways to set it up:

- Centralized: This is like having one super-powerful computer that does most of the heavy thinking. All the data from sensors gets sent to this central brain, which then figures out what to do and sends commands back out.

- Distributed: Here, you have multiple smaller processing units spread throughout the vehicle. Each might handle specific tasks, like processing camera data or managing a particular sensor. They then communicate with each other to coordinate actions.

Each approach has its pros and cons. Centralized systems can be simpler to manage in some ways, but if that one big computer fails, you’re in trouble. Distributed systems can be more resilient, as one unit failing might not bring the whole system down, but coordinating all those separate processors can get complicated. The trend seems to be moving towards a hybrid approach, combining the strengths of both.

Sensor Suites: The Eyes and Ears of Autonomy

Autonomous vehicles need to understand their surroundings, and that’s where sensors come in. Think of them as the car’s eyes and ears, constantly gathering information about the world. Without a good set of sensors, a car is basically flying blind. Most self-driving systems use a mix of different sensors to get a complete picture, and this redundancy is key. If one sensor has a problem, others can pick up the slack.

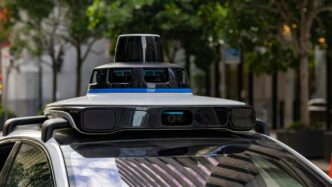

Lidar Systems for Environment Mapping

Lidar, which stands for Light Detection and Ranging, is a pretty neat technology. It works by shooting out laser beams and measuring how long it takes for them to bounce back. This creates a detailed 3D map of everything around the car, like a point cloud. It’s really good at figuring out distances and shapes, even in low light conditions. This makes it super useful for mapping out the environment accurately and detecting obstacles.

Depth Cameras and Visual Recognition

Depth cameras are a bit like our own eyes. They capture images, but they also figure out how far away things are. This is great for visual recognition – think identifying traffic signs or distinguishing between a pedestrian and a lamppost. By combining the visual data with depth information, the car gets a better sense of what’s happening in its path. It’s like giving the car a more human-like way of seeing and understanding objects.

Multimodal Sensor Fusion Strategies

So, you’ve got lidar, cameras, and maybe even radar. The real magic happens when you combine all that data. This is called sensor fusion. Different sensors have different strengths and weaknesses. Radar, for instance, is good at seeing through fog or rain, while cameras are great at reading signs. By fusing the data from multiple sensors, the car can build a more robust and reliable understanding of its environment. It’s like putting together a puzzle where each sensor provides a different piece of the picture. This strategy helps the car make better decisions, especially when conditions aren’t perfect.

Vehicle Dynamics and Robust Motion Control

So, how does an autonomous car actually move? It’s not just about pointing it in a direction and hoping for the best. We’re talking about precise control over how the vehicle handles, turns, accelerates, and brakes. This is where vehicle dynamics and motion control come into play, making sure the car behaves predictably and safely, even when things get a bit wild on the road.

Chassis Configurations for Precise Maneuvering

The underlying structure of the vehicle, its chassis, plays a big role. Think about how different cars handle – a sports car feels way different from a minivan, right? For autonomous vehicles, engineers often look at specific chassis designs that offer better stability and responsiveness. This might involve things like a lower center of gravity to reduce body roll during turns, or a specific suspension setup that can absorb bumps without upsetting the car’s balance. The goal is to have a platform that’s inherently stable and predictable, making the job of the control systems a whole lot easier. It’s like starting with a really solid foundation; it just makes everything else work better.

Drive-By-Wire Actuation and Feedback Systems

Forget about mechanical linkages connecting the steering wheel to the wheels. Modern autonomous vehicles use ‘drive-by-wire’ systems. This means electronic signals are sent from the computer to actuators that control steering, braking, and acceleration. It’s like a digital command chain.

Here’s a simplified look at how it works:

- Command Generation: The main computer decides how much to steer or accelerate.

- Signal Transmission: This decision is sent as an electronic signal.

- Actuation: Electric motors or hydraulic systems physically move the steering rack, apply the brakes, or control the throttle.

- Feedback: Sensors constantly report back the actual state (e.g., wheel angle, speed) to the computer, allowing for fine-tuning and correction. This feedback loop is super important for keeping things accurate.

This closed-loop control is what allows for incredibly precise adjustments, far beyond what a human driver could manage.

Motor Encoders and Odometry Integration

To know exactly how the vehicle is moving, we need to track its wheels. That’s where motor encoders and odometry come in. Motor encoders are sensors attached to the drive motors that measure how much the motor shaft has rotated. By knowing the wheel’s circumference, we can translate this rotation into distance traveled. Odometry is essentially the process of estimating the vehicle’s position and orientation based on these wheel movements. It’s like keeping a running tally of every tiny movement the car makes. This data is vital for:

- Accurate Speed Estimation: Knowing how fast each wheel is turning helps calculate the vehicle’s overall speed.

- Distance Traveled: Tracking wheel rotations gives a precise measure of how far the car has gone.

- Path Following: By integrating these measurements over time, the system can build a picture of the path the vehicle has taken.

- Localization: This information is a key input for more advanced localization systems that figure out where the car is on a map.

Digital Twin and Simulation Platforms in Hardware Validation

Testing autonomous vehicle hardware is a tricky business. You can’t just take a brand new system out on the road and hope for the best, right? That’s where digital twins and simulation platforms come into play. Think of a digital twin as a super-detailed virtual copy of your actual hardware and its environment. It’s not just a pretty 3D model; it’s built with accurate physics, realistic sensor behavior, and even the quirks of the vehicle’s motion.

Role of Simulation Engines for Realistic Testing

Simulation engines are the workhorses here. They create these virtual worlds where you can throw anything at your autonomous system without any real-world risk. We’re talking about simulating everything from sunny days to sudden downpours, from empty highways to chaotic city intersections. The goal is to make the virtual world as close to reality as possible so that what works in simulation is likely to work when you put it on the actual car. This saves a ton of time and money, not to mention avoiding a lot of potential crashes.

Digital Twins for Bridging Virtual and Physical Testing

The real magic happens when the simulation gets really, really good – that’s the digital twin part. It’s like having a perfect virtual replica. If you change something on the physical car, you can update the digital twin to match. This allows for a smooth transition from testing algorithms in the virtual space to testing them on the actual hardware. The closer the digital twin is to the real thing, the smaller the gap between simulation results and real-world performance. This is super important for making sure the software you develop virtually will actually drive the car safely.

Hardware-in-the-Loop (HIL) Validation Techniques

Hardware-in-the-Loop, or HIL, is the next step. Here, you connect the actual hardware components – like the car’s computer and sensors – to the simulation. The simulation sends signals to the hardware as if it were in the real world, and the hardware responds. The simulation then takes those responses and feeds them back into the virtual world. It’s a way to test the real hardware under a huge variety of simulated conditions. It’s a bit like having a super-powered test bench that can mimic any situation you can imagine. This helps catch problems that might only show up when the real electronics are involved.

Scalable and Modular Testbeds for Autonomous Vehicle Hardware

Advantages of Scaled Vehicle Platforms

Full-sized autonomous cars are expensive and a pain to work with, right? That’s where scaled vehicle platforms come in. Think of them as smaller, more manageable versions of the real deal. Platforms like "Nigel" (around 1:14 or 1:5 scale) and the popular "F1TENTH" (1:10 scale) are becoming go-to choices. They’re not just toys; these are sophisticated machines with sensors, actuators for control, and lights. Using these scaled-down versions makes advanced research much more accessible and affordable. It means more people, like university labs or smaller companies, can actually get their hands dirty testing out new ideas without needing a massive budget or a dedicated test track.

Modular Infrastructure for Scenario Reproduction

Having a cool little car is only half the battle. You need a place to test it, and that’s where the modular infrastructure comes in. Imagine building your own mini-city or test course using pre-made road segments and intersections. You can add traffic lights, signs, and even other small vehicles to create specific situations. This setup is great because you can build and rebuild different scenarios easily. It lets you test how your autonomous system handles, say, a tricky intersection or a sudden pedestrian crossing, in a controlled way. Plus, you can repeat the exact same scenario over and over, which is super important for figuring out if your software is actually working reliably.

Accessible Prototyping for Researchers and Developers

What’s really neat about these testbeds is how they’re built with accessibility in mind. The designs and build instructions are often shared openly, meaning you can get detailed guides, lists of parts, and even assembly animations. This open-source approach is a game-changer. It lowers the cost of entry significantly, as you’re not paying for expensive proprietary systems. Researchers and developers can replicate these platforms, modify them, or build upon them. It really helps speed up innovation because everyone can share their improvements and learn from each other. It’s all about making it easier for more people to contribute to the future of autonomous driving.

Integration and Communication Across Hardware Components

So, you’ve got all these fancy pieces of hardware – the sensors, the computers, the actuators – all working together to make a car drive itself. But how do they actually talk to each other? It’s not magic, it’s all about how they’re connected and how the data flows.

APIs and Middleware for System Connectivity

Think of APIs (Application Programming Interfaces) as the translators between different software parts. They define the rules for how one piece of software can ask another piece for information or to do something. For autonomous vehicles, this is super important. You might have a perception system that figures out what’s around the car, and it needs to tell the planning system what it sees. An API makes that conversation happen smoothly. Middleware, like ROS (Robot Operating System), acts like a central nervous system. It provides a bunch of tools and services that help different hardware and software components find each other, send messages, and manage data. Without good APIs and middleware, your autonomous car would be a bunch of isolated gadgets that can’t work as a team.

Data Flow Between Sensors, Processors, and Actuators

This is where the action really is. Data starts with the sensors – cameras, lidar, radar. They collect raw information about the world. This data then gets sent to the processing units, like the GPUs and embedded computers. These guys crunch the numbers, figure out what the data means (e.g., "that’s a pedestrian," "that’s a stop sign"), and make decisions. Finally, these decisions are translated into commands for the actuators – the steering, brakes, and throttle. It’s a constant loop: sense, think, act. The speed and reliability of this data flow are everything. A delay in sending sensor data or a slow decision from the processor could mean the difference between a smooth stop and a fender bender.

Here’s a simplified look at the data path:

| Component | Primary Function |

|---|---|

| Sensors | Gather environmental data (images, distances, etc.) |

| Processors | Analyze data, make decisions, plan actions |

| Actuators | Execute commands (steer, brake, accelerate) |

Ensuring Reliability in Real-World Deployments

Making sure all these connections and data flows are reliable is a huge challenge. You can’t have a sensor drop out or a communication line go dead when the car is on a busy street. Engineers use a few tricks to build in robustness:

- Redundancy: Having backup systems. If one sensor fails, another can take over.

- Error Checking: Constantly checking the data for mistakes or corruption during transmission.

- Fail-Safes: Designing the system so that if something goes wrong, it defaults to a safe state, like slowing down or stopping the vehicle.

- Health Monitoring: Keeping an eye on all the components to detect problems before they cause a failure.

Wrapping It Up

So, we’ve taken a good look at the hardware that makes self-driving cars tick. It’s a lot more than just fancy cameras and sensors; it’s a whole system working together. From the brains processing all the data to the parts that actually make the car move, each piece has its job. Building these systems is complex, and platforms like AutoDRIVE are making it easier for more people to get involved and push the technology forward. It’s exciting to see how this hardware will continue to evolve and shape the future of how we get around.