Understanding What Is Robotics

So, what exactly is robotics? It’s not just about those shiny metal guys from the movies, though they’re part of it. Think of robotics as a field where science, engineering, and technology all come together. The main goal? To create machines, which we call robots, that can do things humans do, or sometimes, do them even better.

Defining Robotics: Science, Engineering, and Technology

At its heart, robotics is about building machines that can perform tasks. This involves a mix of disciplines. You’ve got the science part, figuring out the principles of how things move and interact. Then there’s engineering, which is all about designing and constructing these machines. And finally, technology ties it all together, providing the tools and systems to make it all work. The result is a machine capable of interacting with the physical world. These machines can range from simple automated arms on an assembly line to complex machines exploring other planets.

The Etymology of the Word ‘Robot’

It’s kind of interesting where the word ‘robot’ actually comes from. It wasn’t invented by some tech company in the last century. The term was first used in a 1920 play called R.U.R. (Rossum’s Universal Robots) by a Czech writer named Karel Čapek. He borrowed the word ‘robota’ from the Czech language, which basically means ‘forced labor’ or ‘drudgery’. In the play, robots were artificial workers created to do all the hard, unpleasant jobs. So, right from the start, the idea of robots was tied to performing tasks, often ones humans didn’t want to do.

Robots as Replicators of Human Actions

Many robots are designed to mimic human actions. This could be anything from picking up and placing objects, like a factory robot arm, to performing delicate procedures, like a surgical robot. The idea is to automate tasks that are repetitive, dangerous, or require a level of precision that’s hard for humans to maintain over long periods. While early robots were programmed for very specific, repetitive actions, newer robots, especially those with artificial intelligence, can learn and adapt, making them capable of handling more varied and complex tasks that are closer to human-like decision-making.

Core Components That Power Robots

So, what actually makes a robot tick? It’s not just one thing, but a combination of parts working together. Think of it like building a person – you need a skeleton, muscles, a brain, and a way to get energy. Robots are pretty similar.

Mechanical Construction for Task Completion

This is the robot’s body, the physical structure that lets it do stuff. It’s built from materials like metal, plastic, or even advanced composites like carbon fiber, which is super strong but really light. The design of this mechanical part is all about what the robot needs to do. A robot arm on an assembly line will look very different from a robot designed to explore Mars. These structures have joints and links that allow for movement, and at the very end, there’s often an "end effector." This is like the robot’s hand or tool – it could be a gripper to pick things up, a welding torch, or even a delicate surgical instrument. The way these parts are put together dictates how the robot can move and interact with its environment.

Electrical Components for Power and Control

Robots need power to run, just like we need food. This comes from a power supply, which is usually a battery for mobile robots or a direct plug-in for stationary ones. But it’s not just about having power; it’s about managing it. Advanced systems try to save energy, maybe by slowing down when they don’t need to move fast or even capturing energy when they brake. Then there are the "brains" of the operation, the control systems. These are like the robot’s central nervous system, processing information and sending signals. They contain microprocessors and memory, and for more complex robots, they might even have special chips for artificial intelligence. These controllers take in data from sensors and decide what the robot should do next.

The Essential Role of Software Programming

Without software, a robot is just a bunch of metal and wires. Programming is what gives a robot its purpose and tells it how to carry out tasks. It’s the set of instructions that guides the robot’s actions. This code tells the control system when to activate motors, how much force to apply, or what path to follow. Simple robots might have straightforward programs, but more advanced ones use complex algorithms that allow them to learn and adapt. Software is the intelligence that transforms a mechanical device into a functional robot. It’s the difference between a tool that just sits there and a machine that can actively perform a job, whether that’s building a car, assisting in surgery, or exploring a distant planet.

How Robots Function: The Underlying Mechanics

So, how does a robot actually do things? It’s not magic, though sometimes it sure seems like it. At its core, a robot is a system that takes in information, figures out what to do with it, and then acts on it. Think of it like a very sophisticated, programmable tool.

Data Collection Through Sensors and Cameras

First off, a robot needs to know what’s going on around it. That’s where sensors come in. These are like the robot’s senses. Cameras act as its eyes, letting it see shapes, colors, and movement. Microphones can be its ears, picking up sounds. Other sensors might detect temperature, pressure, or even the distance to an object. All this information is gathered as electrical signals, which are then sent off to be processed. Without these sensors, a robot would be completely blind and deaf to its environment.

Decision-Making Via Control Systems and AI

Once the robot has all this sensory data, it needs to make sense of it and decide what to do next. This is the job of the control system, which is essentially the robot’s brain. It’s a computer that runs software – the program that tells the robot how to behave. For simpler robots, this might be a straightforward set of instructions: ‘If you see an object within 10 cm, stop.’ For more advanced robots, especially those with artificial intelligence (AI), the decision-making can be much more complex. AI allows robots to learn from experience, adapt to new situations, and make more nuanced judgments, much like we do.

Actuators: Bringing Movement to Robotic Systems

Finally, after collecting data and making a decision, the robot needs to actually do something. This is where actuators come into play. Actuators are the parts that create movement. They’re usually motors, but they can also be things like hydraulic or pneumatic systems. When the control system sends a signal, the actuators respond by moving a robot’s arm, turning its wheels, or operating a gripper. It’s this combination of sensing, thinking, and acting that allows robots to perform their programmed tasks, whether it’s assembling a car part or exploring a distant planet.

The Spectrum of Robotic Autonomy

Robots aren’t all the same when it comes to how much they can do on their own. Think of it like a sliding scale, from machines that need a human to hold their hand every step of the way, to ones that can figure things out all by themselves. It really depends on what the robot is built for and how complex its job is.

Human-Controlled and Semi-Autonomous Robots

These are the robots that still need a lot of human input. In the case of fully human-controlled robots, a person is essentially driving the robot, either directly or through a remote interface. It’s like playing a video game, but with a real machine. Semi-autonomous robots are a bit more independent. They can perform certain tasks on their own, but they still need humans to set them up, monitor their progress, or step in when things get tricky. For example, a robot arm on an assembly line might be programmed to do a specific welding job, but a human operator needs to load the parts and make sure the weld looks good.

- Direct Control: A human operator uses joysticks, controllers, or even gestures to move the robot and make it perform actions. Think of remote-controlled bomb disposal units.

- Pre-programmed Tasks: The robot follows a set sequence of instructions. It can repeat these tasks endlessly, but it can’t deviate or handle unexpected issues.

- Supervised Operation: The robot performs tasks autonomously within defined parameters, but a human is present to oversee, intervene if necessary, and handle exceptions.

Fully Autonomous Robots in Action

This is where robots get really interesting. Fully autonomous robots are designed to operate without any human intervention. They use sensors to understand their surroundings, make decisions based on that information, and then act on those decisions. These robots are the ones that can adapt to changing environments and handle tasks that weren’t specifically programmed into them. Think of self-driving cars or advanced drones that can map an area and identify targets on their own. Developing these robots is tough because the real world is messy and unpredictable. Even the most advanced ones, like Tesla’s Optimus, still have a long way to go before they can handle everyday human environments reliably. They might work great in a controlled lab setting for a short demo, but ask them to navigate a busy factory floor or a cluttered home, and they’ll likely run into problems.

Teleoperated Robots for Remote Operations

Teleoperation is a bit of a hybrid. It’s not fully autonomous, but it’s also not direct human control in the same room. Instead, a human operator controls a robot from a distance. This is super useful for jobs that are too dangerous, too far away, or too delicate for humans to do directly. Imagine a surgeon controlling a robotic arm to perform surgery on a patient miles away, or a scientist operating a rover on Mars. The operator gets feedback from the robot, like video feeds and sensor data, to guide its actions. It’s like having a pair of robotic hands and eyes that you can control from anywhere.

- Remote Presence: Allows humans to interact with environments they cannot physically access.

- Hazardous Environments: Ideal for tasks in radioactive areas, deep underwater, or in disaster zones.

- Precision Tasks: Enables complex operations like microsurgery or intricate repairs in hard-to-reach places.

Key Technologies Driving Robotics Forward

So, what’s really making robots smarter and more capable these days? It’s a mix of some pretty cool tech that’s been developing for a while. Think of it like building blocks – each piece adds something new.

Artificial Intelligence and Machine Learning

This is a big one. AI, especially machine learning, is what lets robots learn and get better without us having to reprogram them for every little thing. Instead of just following a set of instructions, AI allows robots to figure things out. They can look at a situation, make a decision, and even adapt if things change. For example, a robot in a warehouse might learn the most efficient way to pick and place items based on past performance, or a self-driving robot might get better at recognizing obstacles over time. This ability to learn and adapt is what separates basic machines from truly intelligent robotic systems.

Sensors and Perception Systems

Robots need to understand the world around them, right? That’s where sensors come in. We’re talking about cameras that can see, LiDAR that can map out spaces, and all sorts of other sensors that detect touch, temperature, or even sound. By combining the data from these different sensors, a robot can build a pretty detailed picture of its environment. It’s like giving the robot eyes, ears, and a sense of touch. Without good sensors, a robot would be pretty lost, bumping into things and unable to do its job effectively.

Advanced Control Systems and Processing

Once a robot has gathered information from its sensors and made a decision using its AI, it needs a way to actually do something. That’s where control systems and processing power come in. These are the robot’s "brain" and "nervous system." They take all the data, run the AI algorithms, and then send precise commands to the robot’s motors and other parts to make it move. Modern robots use powerful processors, sometimes even specialized chips, to handle these complex calculations very quickly. This allows for smooth, precise movements and fast reactions, which is super important for tasks that require accuracy or speed.

Applications of Robotics Across Industries

Robots aren’t just for sci-fi movies anymore; they’re showing up everywhere, making our lives easier and industries more productive. It’s pretty wild how far this tech has come.

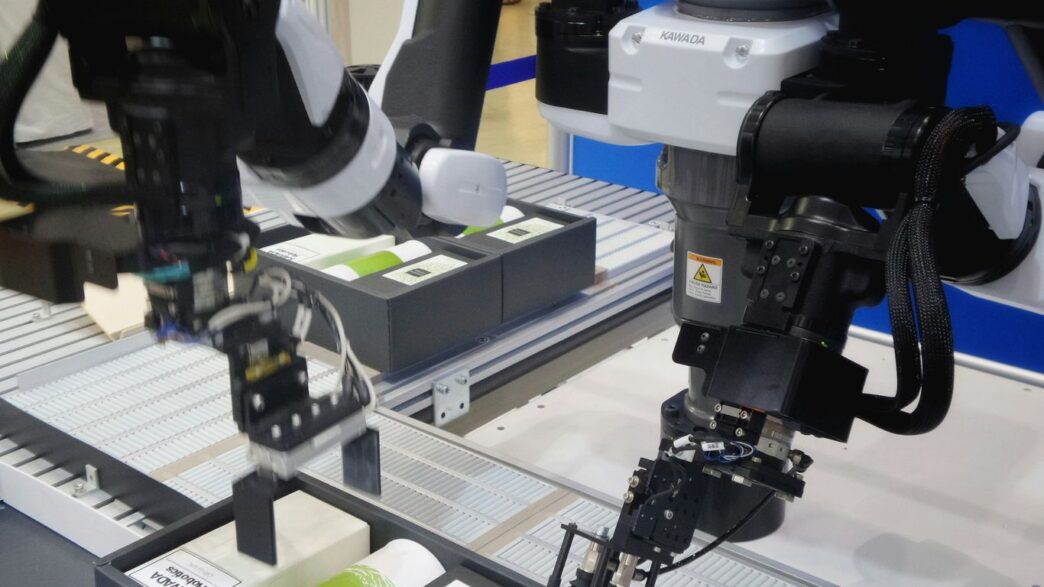

Robotics in Manufacturing and Assembly

This is where robots really got their start, and they’re still a huge deal. Think car factories – those robotic arms welding and painting car parts? That’s robotics in action. They can do repetitive jobs super fast and without getting tired, which means more stuff gets made, and usually with fewer mistakes. Companies are using them for everything from putting tiny electronic components together to moving heavy materials around a warehouse. It’s not just about replacing people, either. We’re seeing more "cobots" – collaborative robots – that work right alongside humans, helping out with tasks and making the whole process smoother.

Healthcare and Surgical Assistance

In hospitals, robots are becoming pretty important. You might have heard about surgical robots, like the da Vinci system. These aren’t robots doing surgery on their own, but rather tools that help surgeons be more precise, especially in tricky operations. This can mean smaller cuts, less pain for patients, and quicker recovery times. Beyond the operating room, robots are helping with things like delivering medications or supplies within the hospital, freeing up nurses and doctors to focus on patient care. There are even robots designed to help people recover from injuries, assisting with physical therapy.

Space Exploration and Military Use

When humans can’t go, robots can. NASA’s Mars rovers are a perfect example. These robots are basically robotic explorers, driving around on another planet, taking pictures, and analyzing rocks. They can go places that would be too dangerous or impossible for people. In the military, robots are used for tasks like checking for bombs, scouting out areas, or carrying supplies. Drones, which are essentially flying robots, are also used a lot for gathering information without putting soldiers in harm’s way.

Consumer and Smart Home Applications

Robots are also making their way into our homes. Think about robot vacuums that clean your floors all by themselves – pretty neat, right? Smart home devices are getting more sophisticated too, with some systems able to manage your lights, thermostat, and security. While these might not be as complex as industrial robots, they’re all part of the same trend: using automation to make everyday life more convenient. We’re also seeing robots designed for companionship or to help older adults live more independently.

Wrapping It Up

So, there you have it. Robotics isn’t just about shiny metal people walking around; it’s a whole field of engineering and science focused on making machines that can do stuff for us. From the nuts and bolts that make them move to the code that tells them what to do, it’s a pretty complex mix. Whether it’s building cars, helping surgeons, or even exploring other planets, robots are already a big part of our world, and they’re only going to become more common. It’s pretty wild to think about how far we’ve come and where it’s all headed next.