So, you’re trying to figure out how is CNC machining different from 3D printing? It’s a common question, especially when you’re looking at making parts or prototypes. Both methods use computers to guide tools, but they go about it in fundamentally different ways. Think of it like building with LEGOs versus carving a sculpture from a block of wood. One adds pieces, the other takes them away. Let’s break down what that really means for your projects.

Key Takeaways

- CNC machining is subtractive, carving material away from a block, while 3D printing is additive, building parts layer by layer.

- CNC machining generally offers higher precision and better material properties, making it ideal for functional parts and strong prototypes.

- 3D printing excels at creating complex geometries and intricate designs that would be difficult or impossible to machine.

- Material options are broader for CNC machining, capable of working with a wide range of metals and plastics, whereas 3D printing has specific material limitations.

- Cost and speed vary: 3D printing is often faster and cheaper for initial prototypes or small batches, while CNC machining can be more cost-effective for larger production runs or when high accuracy is needed.

Understanding The Core Manufacturing Philosophies

Additive Versus Subtractive Processes

When you’re trying to make something, there are basically two main ways to go about it: you can either build it up from scratch or carve it out of something bigger. This is the heart of the difference between 3D printing and CNC machining.

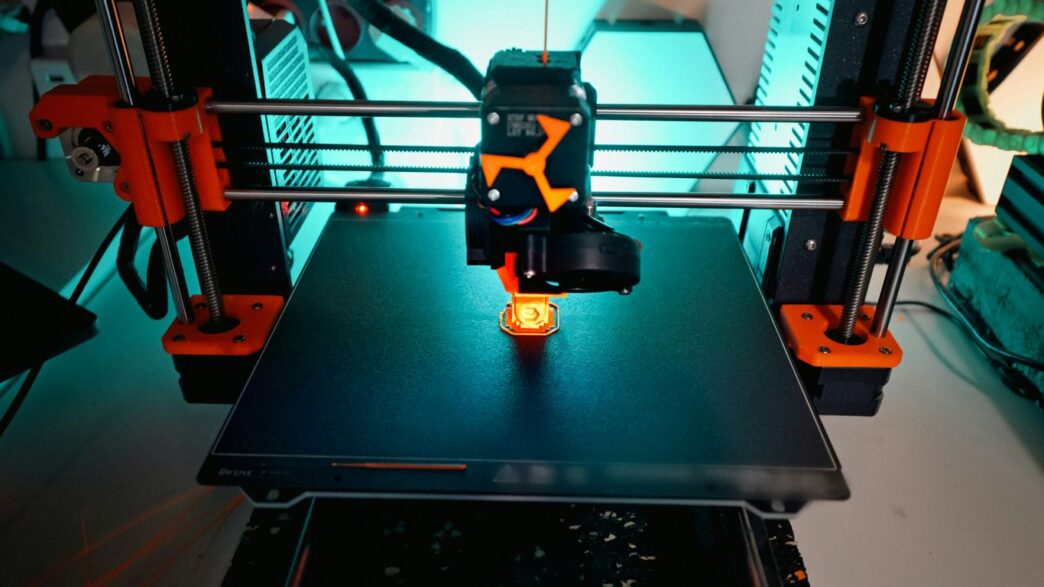

3D printing is an additive process. Think of it like building with LEGOs. You start with nothing and add material, layer by layer, until you have your final part. It’s great for creating complex shapes because you’re just adding material where you need it. You can make hollow parts or intricate internal structures pretty easily.

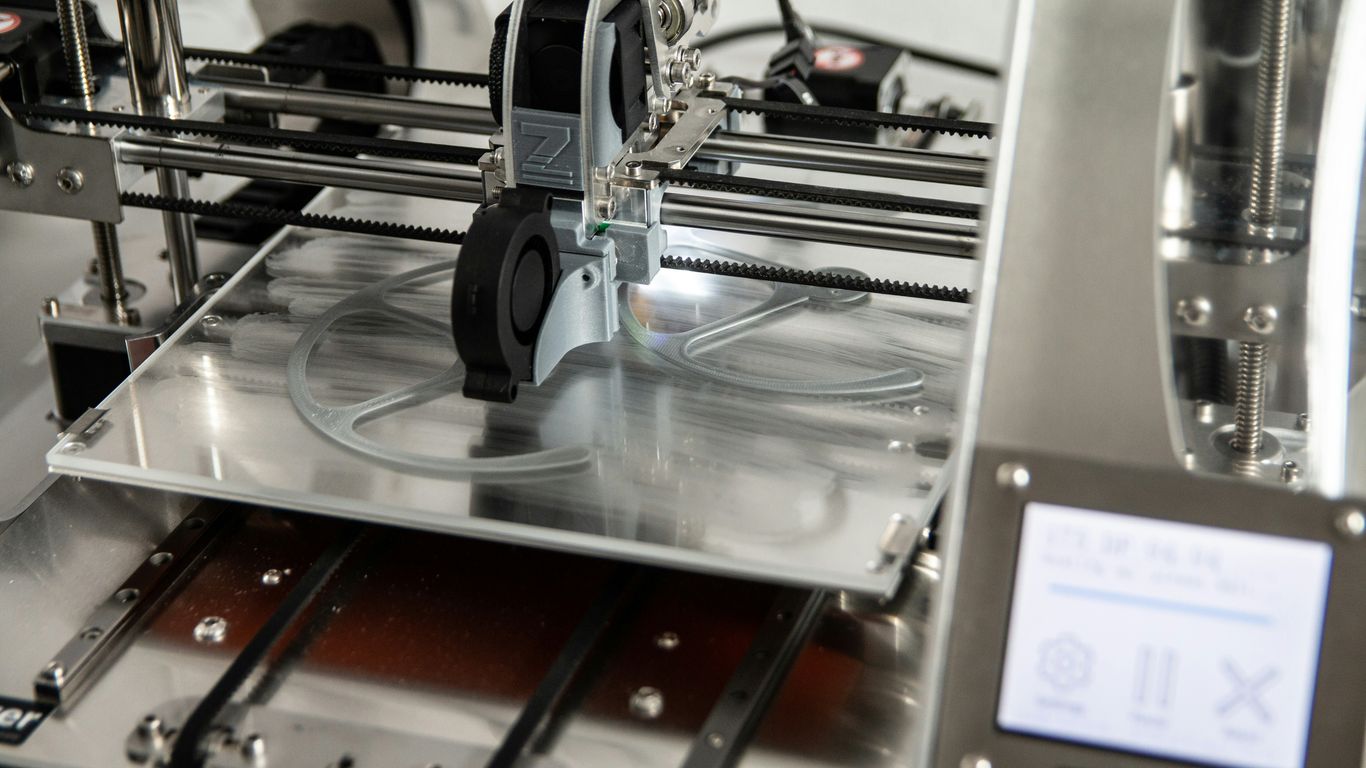

CNC machining, on the other hand, is a subtractive process. Imagine a sculptor starting with a block of marble and chipping away everything that isn’t the statue. That’s what CNC machining does. It takes a solid block of material – like metal or plastic – and uses cutting tools to remove the excess, shaping it into the desired part. This method is really good for making parts that need to be strong and precise, especially from metals.

Here’s a quick rundown:

- Additive (3D Printing): Builds parts layer by layer. Good for complex geometries and internal features. Less material waste in some cases.

- Subtractive (CNC Machining): Removes material from a solid block. Excellent for strong, precise parts, especially from metals. Can generate more waste material.

Historical Development Of Each Technology

These two methods have pretty different timelines. CNC machining has been around in some form for a long time. Basic machining techniques, like using lathes and mills, go back centuries. The ‘CNC’ part – meaning Computer Numerical Control – really took off in the mid-20th century as computers became more accessible and powerful. It allowed for much more precise and automated control over the cutting tools.

3D printing, or additive manufacturing, is a much newer kid on the block. The first patents for processes like stereolithography (one of the earliest forms of 3D printing) appeared in the late 1980s. For a long time, 3D printing was mostly used for making quick prototypes to test out designs. But lately, especially with industrial-grade machines, it’s become capable enough for making actual end-use parts, not just models.

Exploring Material Capabilities And Properties

When you’re trying to figure out how to make a part, the materials you can use are a pretty big deal. It’s not just about what looks good; it’s about what will actually work for what you need it to do. Both CNC machining and 3D printing have come a long way, and they both offer a decent selection of materials, but they aren’t exactly the same.

Diversity Of Material Options

CNC machining really shines when it comes to metals. You’ve got a whole menu of options like aluminum, brass, copper, stainless steel, and even titanium. If you’re working with plastics, the list is even longer, including things like ABS, Nylon, Polycarbonate, and PEEK. It’s like a well-stocked hardware store for materials. 3D printing, on the other hand, has been catching up fast. While it also offers metals like aluminum and stainless steel, and plastics like Nylon and ABS, its strength is often in more specialized or composite materials, and it can handle things like photopolymers and silicones which are trickier for traditional machining.

Here’s a quick look at what you can generally find:

- CNC Machining:

- Metals: Aluminum, Brass, Steel Alloys, Titanium, Copper

- Plastics: ABS, Acetal, Nylon, Polycarbonate, PEEK, PTFE

- 3D Printing:

- Metals: Stainless Steel, Titanium, Aluminum Alloys, Cobalt Chrome

- Plastics: ABS-like resins, Nylon (PA), Polypropylene, PC-like resins

- Elastomers: TPU, Silicone, Photopolymers

Material Strength And Durability

Generally speaking, parts made through CNC machining tend to be stronger and more durable. This is because you’re starting with a solid block of material and shaping it, so you retain the inherent properties of that material. Think of it like carving a statue from a block of marble – the marble itself is solid and strong. 3D printed parts, especially those made with plastics, can sometimes be weaker, particularly between the layers they’re built upon. However, advancements in metal 3D printing are closing this gap significantly, and for certain applications, the strength is comparable. For applications demanding the absolute highest mechanical strength and long-term durability, CNC machining often has the edge.

Surface Finish And Post-Processing

Neither method always spits out a perfectly smooth part right off the bat. Machined parts can sometimes have tool marks or a slightly rough texture, often referred to as "as-machined." 3D printed parts can have visible layer lines or a "stairstep" effect, depending on the printing technology and orientation. The good news is that both can be improved. CNC parts can be polished, anodized, plated, or painted. 3D printed parts can be sanded, polished, vapor smoothed, or even undergo secondary machining operations to achieve a smoother finish. Sometimes, the best approach is to use 3D printing for the complex shape and then use CNC machining for critical surfaces that need to be perfectly smooth or precise.

Evaluating Precision, Tolerances, And Complexity

When you’re trying to get a part exactly right, how precise does it need to be, and how complicated can the shape get? This is where CNC machining and 3D printing really show their different strengths.

Achieving High-Precision Requirements

CNC machining is generally the go-to when you need parts that are super accurate. Think about parts for engines, medical devices, or aerospace components – they often need to fit together perfectly and work reliably. Machining cuts away material from a solid block, which gives you a lot of control over the final dimensions. This subtractive process is excellent for hitting tight tolerances, often down to a few thousandths of an inch. While 3D printing has gotten much better, achieving that same level of consistent, high precision, especially with metals, can still be a challenge without extra steps.

Handling Intricate Geometries

This is where 3D printing often shines. Because it builds parts layer by layer, it can create shapes that would be impossible or extremely difficult with traditional machining. We’re talking about internal channels, complex lattice structures, or parts with hollow sections that don’t need assembly. CNC machining, on the other hand, is limited by the tools that can reach the material. If a cutting tool can’t get to a certain spot, you can’t machine it directly. This means very complex internal features are usually out of reach for machining alone.

Design Limitations And Considerations

So, what does this mean for your design? If your part has a relatively simple shape but needs to be incredibly accurate and strong, CNC machining is probably your best bet. It’s great for parts that look like they came straight off a production line, even if you only need a few. However, if your design is wild and complex, with lots of internal details or organic shapes, 3D printing is likely the way to go. It lets you explore more creative designs without worrying as much about how a tool will access every nook and cranny. Sometimes, the best solution is a combination: 3D print a complex part and then use CNC machining to finish critical surfaces or features that need that extra precision.

Comparing Machine Mechanics And Operational Forces

When you look at how CNC machines and 3D printers actually work, there are some pretty big differences in their mechanics and the forces involved. It’s not just about the tools they use; it’s about how the whole machine is built to handle those tools.

Rigidity Versus Nimbleness

Think about a CNC mill. It’s built like a tank, and for good reason. The cutting tool is literally digging into a solid block of material. This means the machine needs to be incredibly rigid to avoid wobbling or vibrating. Any flex in the frame or the moving parts can mess up the accuracy of the cut. That’s why you see heavy-duty linear guides or sliding dovetails on milling machines – they’re all about keeping things solid.

Now, a 3D printer is a different beast. The print head, or hotend, is just skimming over the part, laying down melted plastic. There aren’t huge forces pushing back against it. So, 3D printers can get away with lighter frames and, often, flexible belts for movement. While this makes them nimble and capable of complex movements, it’s not ideal for cutting.

Forces Experienced During Operation

The forces are where things really diverge. In CNC machining, the cutting tool is actively removing material. This creates significant forces that push and pull on the tool and the workpiece. If the machine isn’t rigid enough, these forces cause deflection, leading to inaccuracies, chatter marks, or even tool breakage. It’s like trying to carve a statue with a flimsy butter knife – you just won’t get clean results.

On the flip side, 3D printing involves much lower forces. The main forces are related to the movement of the print head and the bed, and the extrusion of plastic. While precise movement is still important, it doesn’t compare to the cutting forces in milling. This is why you often see 3D printers using elastic belts, which would be a disaster for a milling machine trying to cut metal or hard plastics.

Speed And Efficiency Differences

Because of the rigidity and the nature of the forces, CNC machines and 3D printers operate at different speeds and efficiencies. CNC machines, while sometimes slower in terms of overall build time for a single complex part, are incredibly efficient at removing material once set up. They can often produce finished parts much faster than a 3D printer for certain types of jobs, especially when you need high accuracy and strength.

3D printers, on the other hand, can be faster for creating intricate, one-off prototypes where the complexity of the shape is the main challenge. However, the layer-by-layer building process can be slow, especially for larger or solid parts. The efficiency of a 3D printer is often measured in how quickly it can produce a complex shape, not necessarily in material removal rate. It’s a trade-off between speed of iteration and speed of material processing.

Analyzing Cost, Speed, And Production Viability

When you’re trying to figure out the best way to make a part, cost and speed are usually pretty high on the list of things to think about. It’s not just about how much it costs to make one part, but also how long it takes to get that first part, and then how many you can churn out over time. This is where CNC machining and 3D printing really start to show their differences.

Initial Setup And Iteration Costs

Getting started with either method has its own costs. For CNC machining, you often need to factor in the cost of programming the machine, setting up the workpiece, and potentially creating custom tooling if your part is complex or you’re using unusual materials. This initial investment can be higher, especially for one-off parts or very small batches. However, once the setup is done, making more identical parts can become quite efficient.

3D printing, on the other hand, often has a lower barrier to entry for the initial setup. You load a digital file, and the machine starts building. This makes it really attractive for quick iterations. If you need to tweak a design and print it again, it’s usually faster and cheaper to do so with 3D printing than to re-program and re-tool for CNC. This flexibility in iteration is a big win for 3D printing during the early design phases.

Cost-Effectiveness For Different Volumes

The sweet spot for each technology really depends on how many parts you need.

- Low Volumes (1-50 parts): 3D printing often wins here. The per-part cost doesn’t drop dramatically with quantity, making it economical for prototypes, custom one-offs, or very small production runs. It avoids the high upfront tooling costs associated with traditional manufacturing.

- Medium Volumes (50-500 parts): This is often a grey area. Depending on the part’s complexity and material, both methods can be competitive. 3D printing might still be faster for complex geometries, while CNC could be more cost-effective for simpler parts if setup costs are amortized.

- High Volumes (500+ parts): CNC machining generally becomes the more cost-effective option for larger quantities. The per-part cost decreases significantly as the initial setup and tooling costs are spread across many units. For very high volumes, other methods like injection molding might even become more economical than CNC.

Time To First Part And Throughput

When you need a part now, time is of the essence. 3D printing typically excels at getting that very first part into your hands quickly. You can often have a functional prototype within hours or a day, depending on the size and complexity. This speed is fantastic for rapid prototyping and validating designs early on.

CNC machining, while potentially slower for the first part due to setup, can achieve much higher throughput once it’s running. If you need hundreds or thousands of identical parts, a CNC machine can often produce them faster per unit than a 3D printer, especially for simpler geometries. The overall production speed for a large batch can therefore be much greater with CNC, even if the initial time to the first part is longer.

Considering Practical Aspects Of Each Method

When you’re actually making parts, not just designing them, a few other things pop up that can make a big difference in your choice between CNC machining and 3D printing. It’s not all about the final product’s specs; sometimes, it’s about the mess, the noise, and what’s left over.

Waste Material and Environmental Impact

This is a pretty big one for a lot of companies these days. CNC machining, being a subtractive process, tends to create more waste. Think of all the chips and shavings that come off a block of metal or plastic – that’s material that’s being removed and often can’t be easily reused. 3D printing, on the other hand, is additive, meaning it builds parts layer by layer. Generally, this means less material is wasted, especially for complex shapes where machining would have to remove a lot of excess material. However, support structures in 3D printing can also contribute to waste, and not all 3D printing materials are easily recyclable.

- CNC Machining: Generates significant waste in the form of chips and swarf. Recycling options for these byproducts vary depending on the material.

- 3D Printing: Typically produces less waste material, as parts are built up layer by layer. Waste comes mainly from support structures and failed prints.

Noise Levels and Operational Environment

If you’re planning to set up your manufacturing process in a shared space or even a home workshop, the noise factor is something to consider. CNC machines, with their high-speed cutting tools and powerful motors, can be quite loud. They often require dedicated spaces with sound dampening. 3D printers, especially FDM (Fused Deposition Modeling) types, are generally much quieter, often comparable to a loud office printer or a small fan. Some industrial 3D printers can still be noisy, but it’s usually less intense than machining.

Tooling and Automation Differences

When you’re thinking about setting up a production line, the tools and how automated things can get are important. CNC machining often requires specific cutting tools for different operations and materials. While these tools can be automated in tool changers, there’s still a need for tool management and replacement. 3D printing, in many cases, doesn’t require specialized cutting tools; the print head or laser is the primary

So, Which One Wins?

Alright, so we’ve gone over the nitty-gritty of how CNC machining and 3D printing do their thing. It’s pretty clear they’re not really interchangeable, even though they both use computer controls. Think of it like this: 3D printing is like building with LEGOs, adding piece by piece to create something. CNC machining, on the other hand, is more like sculpting, starting with a big block and carving away until you get your final shape. Each has its own strengths. If you need something super strong, made from tough materials, or with really tight measurements, CNC is probably your best bet. But if you’re looking to create complex shapes quickly, test out a bunch of ideas fast, or work with plastics without needing fancy molds, 3D printing is a solid choice. Often, the best part isn’t picking one over the other, but figuring out which one, or maybe even a combination of both, makes the most sense for your specific project. It really just depends on what you’re trying to make and what’s most important to you – speed, material, or accuracy.