Advancements Driving Robotic Capabilities

Robots used to be pretty much stuck in factories, doing the same thing over and over. They were expensive, clunky, and couldn’t really handle anything outside their programmed tasks. But things are changing, fast. A bunch of cool stuff happening in both hardware and software is making robots way more useful and, honestly, a lot more interesting.

The Hardware Revolution: Smaller, Cheaper, More Capable

Think about the parts that make up a robot. Things like motors, batteries, sensors, and the little computer chips inside have gotten way better and cheaper over the last decade. This means we can build robots that are not only more powerful but also smaller and less expensive. We’re seeing all sorts of new robot designs, from little drones that zip around to more complex machines that look a bit like us.

Plus, batteries are lasting longer, and materials are lighter. This lets robots move around more freely and work for longer stretches without needing a recharge. It’s a big shift from those old, rigid machines to systems that can actually move through different places, pick things up carefully, and even interact with people.

Software Breakthroughs: AI and Spatial Intelligence

On the software side, artificial intelligence (AI) is making huge leaps. New AI models can now understand all sorts of information at once – text, pictures, sounds, and even 3D space. This is starting to give robots a sense of "spatial intelligence." They can begin to figure out what’s around them, recognize objects in context, and make smarter decisions about what to do next.

It’s like giving robots a better understanding of the physical world. They can start to grasp their own position and how to move and interact with things more effectively.

Bridging the Gap: Proprioception and Real-World Data

One of the trickier parts for robots has been figuring out their own body and how it relates to the world – this is called proprioception. It’s like knowing where your hand is without looking at it. Getting AI to learn this for real-world robots is tough because there isn’t always enough good data. But people are getting creative.

They’re using computer simulations, basically creating virtual worlds with realistic physics, to train robots. This way, robots can learn and make mistakes in a digital space before they’re ever let loose in the real world. It’s a smart way to speed up learning and make robots more ready for whatever they encounter.

Transforming Industries with Automation

Robots used to be mostly stuck on assembly lines, doing the same thing over and over in factories. That’s changing, though. Thanks to cheaper parts and smarter software, robots are starting to show up in places that are way more complicated and unpredictable.

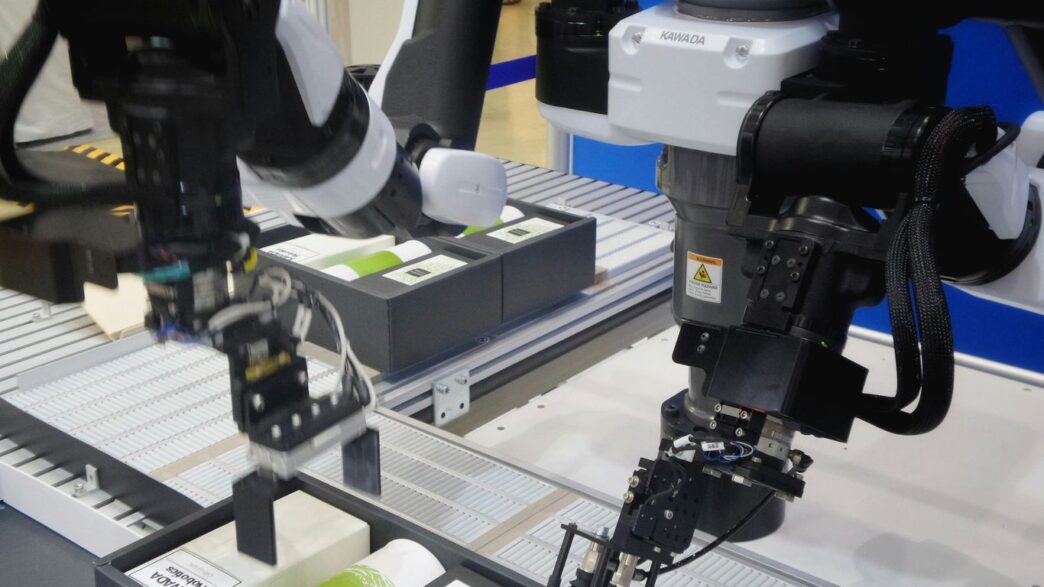

The Evolution of Industrial Robotics

For a long time, if you wanted robots, you needed a lot of money upfront and a very controlled environment. Think car manufacturing, where everything is predictable. But now, the cost of things like motors, sensors, and batteries has dropped a lot. This means robots are becoming more flexible. They can move around, grab things more carefully, and even work alongside people better than before. Warehouses and delivery services have already seen a big shift, but now other industries are catching on.

Automating Construction and Infrastructure

Building things and keeping them in good shape has always had problems with not enough workers, going over budget, and just being slow. Robotics is stepping in to help. There are new companies making robots that can help build things like power grids faster and with less manual labor. Others are creating robotic ways to make complex building parts, which could lead to totally new building designs. We’re even seeing big construction machines being automated to make job sites safer and more efficient. Plus, robots with cameras and sensors can constantly check on things like roads and power lines, spotting problems before they get expensive to fix.

Enhancing Energy Infrastructure and Manufacturing

In the energy sector, robots are being used to speed up the building of new infrastructure, cutting down on the need for people to do dangerous or repetitive tasks. For manufacturing, especially in areas like construction, robots are enabling the creation of intricate components that were previously too difficult or costly to produce. This opens up new possibilities for design and construction methods. The falling costs of these systems make them a practical choice for industries that have a lot of physical assets to manage.

The Investment Landscape in Robotics

It feels like just yesterday that robots were mostly stuck on factory floors, doing the same thing over and over. But things are changing, and fast. Venture capital money is pouring into robotics like never before, and 2024 was a huge year for it. We’re seeing more startups pop up everywhere, tackling all sorts of problems with robots.

A New Frontier for Venture Capital

So, why all the sudden interest? Well, the tech itself has gotten way better and, importantly, cheaper. Think about it: motors, batteries, sensors – they’re all more powerful and cost less than they used to. This means robots can do more, move better, and last longer on a single charge. Plus, the software side has made huge leaps. Artificial intelligence, especially the kind that helps robots understand where they are and what’s around them, is getting really smart. This combination of better hardware and smarter software is opening up a whole new world for what robots can do.

Focus on Foundational Technologies

While there are tons of companies building robots for specific jobs, like building houses or inspecting power lines, a lot of the smart money is going into the underlying tech. This includes things like the operating systems that run robots, platforms for managing fleets of robots, and the core AI that makes them intelligent. It’s like investing in the plumbing and electricity for a whole city, rather than just one house. These foundational pieces are what will allow thousands of different robots to work together and scale up.

The Rise of Robotics-as-a-Service Models

Buying a bunch of robots outright can be a massive expense for businesses. That’s where the "Robotics-as-a-Service" (RaaS) model comes in. Instead of buying, companies can rent or subscribe to robotic solutions. This lowers the barrier to entry, making automation accessible even for smaller businesses or those in industries that haven’t traditionally used a lot of robots, like construction or agriculture. It’s a much more flexible way to adopt new technology. Here’s a quick look at how RaaS can help:

- Reduced Upfront Costs: Businesses don’t need huge capital to start using robots.

- Scalability: Easily add or remove robots as needs change.

- Maintenance Included: Often, the service provider handles upkeep and repairs.

- Access to Latest Tech: Companies can upgrade to newer models without buying them outright.

Empowering the Next Generation with Robotics

It’s pretty wild how much technology is changing, right? And when we talk about the future, robots are a huge part of that picture. Getting kids involved with robotics now isn’t just about playing with cool gadgets; it’s about giving them a real head start. Think of it as building a toolkit for whatever comes next.

Cultivating Creativity and Critical Thinking

Robotics projects are like a blank canvas for young minds. Kids can dream up and build robots that look like anything – a little helper bot, a drone, or even something that mimics an animal. This freedom to experiment and come up with new ideas keeps them curious and engaged. It’s not just about following instructions; it’s about figuring out how to make something work, which really sharpens their thinking skills. When a robot doesn’t do what they expect, they have to stop, look at the problem, and figure out a solution. That’s critical thinking in action, and it’s a skill that helps with everything, from schoolwork to everyday challenges.

Hands-On Learning and Problem-Solving Skills

Let’s be honest, sometimes reading about things just doesn’t cut it. Robotics is all about learning by doing. Kids get to physically build robots, connect wires, and write code. This hands-on approach makes complex ideas, like how gears work or how a program makes a robot move, much easier to grasp. It’s way more interesting than just looking at diagrams. And when things go wrong – which they often do, even for grown-ups trying to fix things – kids learn to stick with it. They learn that mistakes are just part of the process. This builds resilience and teaches them how to tackle problems head-on, rather than giving up. It’s a great way to build confidence because they see that they can figure things out.

Introducing Essential Coding and STEM Concepts

Coding is becoming a basic skill, like reading or writing, and robotics offers a really fun way to get started. Kids use programming languages, often visual ones like Scratch or block-based coding, to tell their robots what to do. They can make a robot move forward, turn, pick something up, or even react to its surroundings. This isn’t just about making a toy move; it’s about understanding logic and sequences. It also naturally introduces them to science, technology, engineering, and math (STEM) concepts without feeling like a chore. They start to see how these subjects connect and how they can be used to create something real and interactive. It’s a fantastic way to spark an interest that could lead to future studies or even a career.

The Software Layer for Scalable Robotics

So, we’ve got these amazing robots getting cheaper and smarter, right? But how do we actually get them to work together, especially when you have a whole bunch of them doing different jobs? That’s where the software layer comes in. It’s like the conductor of an orchestra, making sure all the different instruments (robots) play in harmony.

Fleet Management for Diverse Robot Fleets

Imagine a warehouse with fifty robots. Some are picking orders, others are moving pallets, and a few are cleaning the floors. You can’t possibly manage each one individually. That’s why fleet management software is a game-changer. It lets you oversee the entire group, assign tasks, monitor performance, and even update all the robots at once. This centralized control is key to making robotics practical on a large scale. It means you can deploy robots from different manufacturers and still have them work together without a hitch.

Simulation Tools for Pre-Deployment Testing

Before you send a new robot or a whole fleet out into the real world, you want to know it’s going to work. Sending robots into a busy factory or a construction site without testing is just asking for trouble. Simulation tools create digital twins – virtual copies of your environment. You can then test how your robots will move, interact, and perform tasks in this digital space. It’s like practicing a play before the big performance. This saves a ton of time and money by catching problems early, before they cause real-world delays or damage.

Making Robotics More Accessible and Manageable

Ultimately, all these software advancements are about making robots easier for more people and businesses to use. Think about it: if you need a team of highly specialized engineers just to get a few robots running, that’s a huge barrier. The goal is to create software that’s intuitive, perhaps even using simple interfaces or AI assistants. This way, companies that aren’t robotics experts can still benefit from automation. It’s about taking complex technology and making it manageable, so more businesses can adopt it and see the benefits.

Why Robotics is Essential Today

Robots aren’t just for sci-fi movies anymore. They’re becoming a big part of our everyday lives, and for good reason. Think about it: we’re facing some pretty big challenges, and robots are stepping up to help.

Addressing Labor Shortages and Inefficiencies

Lots of industries are finding it hard to find enough workers. This isn’t just a minor inconvenience; it can really slow things down and make businesses less productive. Robots can fill these gaps, especially in jobs that are repetitive, physically demanding, or just plain dangerous. They can work around the clock without getting tired, which helps keep things moving smoothly. This means businesses can keep up with demand and operate more efficiently.

Improving Safety and Productivity

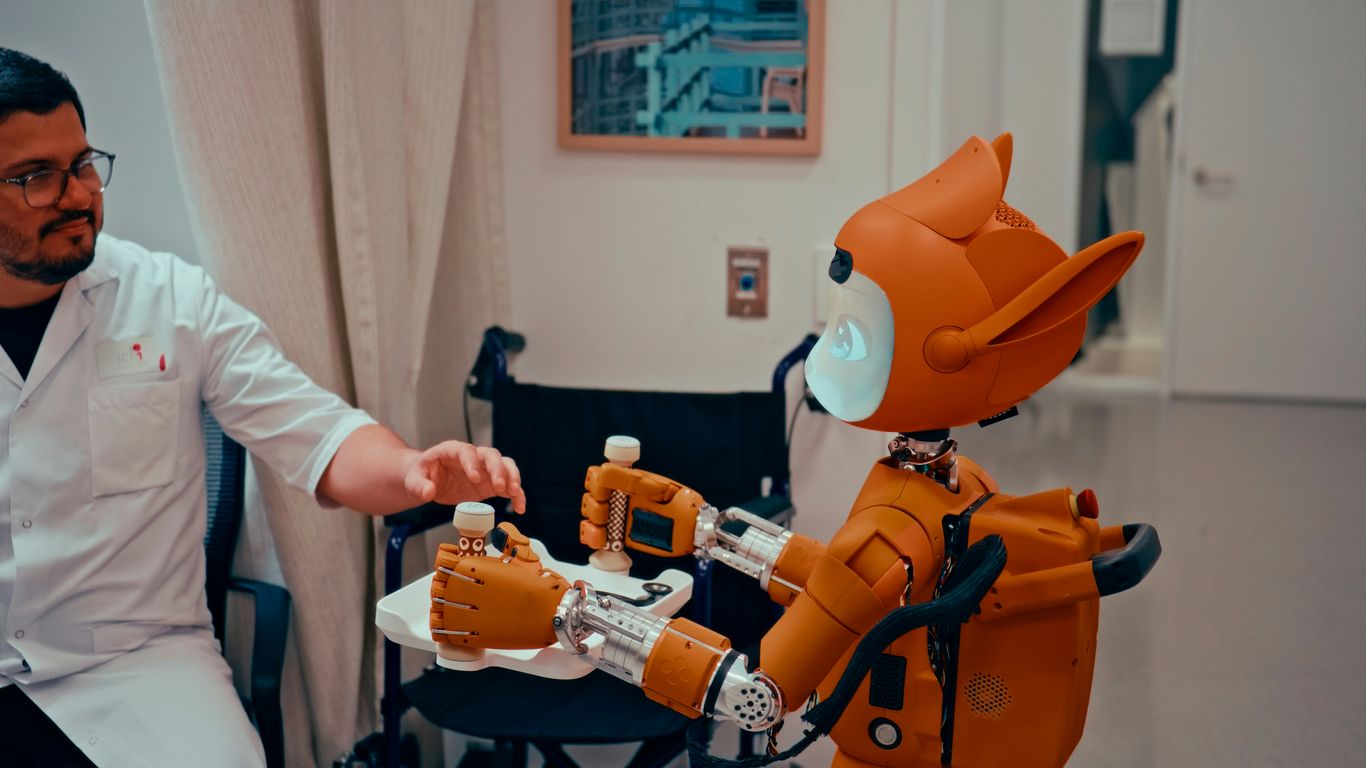

Let’s be honest, some jobs are risky. Working with heavy machinery, handling hazardous materials, or performing tasks in unstable environments puts people in danger. Robots can take on these high-risk tasks, keeping human workers out of harm’s way. This leads to fewer accidents and a safer workplace overall. Plus, robots are often more precise and consistent than humans, which can significantly boost productivity and the quality of work. Imagine a factory floor where robots handle the heavy lifting and dangerous welding, while humans focus on quality control and complex assembly. It’s a win-win.

Driving Innovation and Future Opportunities

Robots are also pushing the boundaries of what’s possible. They’re helping us explore new frontiers, from deep-sea research to space exploration. In medicine, robotic surgery is making procedures less invasive and recovery times shorter. The continued development and integration of robotics are not just about solving today’s problems; they’re about creating new possibilities and shaping a more advanced future. As the technology gets better and cheaper, we’ll see robots doing even more amazing things, opening up new fields and career paths we can’t even imagine yet.

So, What’s Next?

Look, robots aren’t just for sci-fi movies anymore. They’re showing up everywhere, from helping build things to keeping our infrastructure in good shape. The tech is getting better and cheaper, and the software is catching up fast, letting robots do more complex jobs. It’s not just about making factories run smoother; it’s about tackling big challenges in areas like construction and energy. As these machines get smarter and more adaptable, they’re going to change how we work and live. Investing in the tools and systems that make all this possible seems like the smart move. The future is looking pretty automated, and it’s exciting to see what comes next.