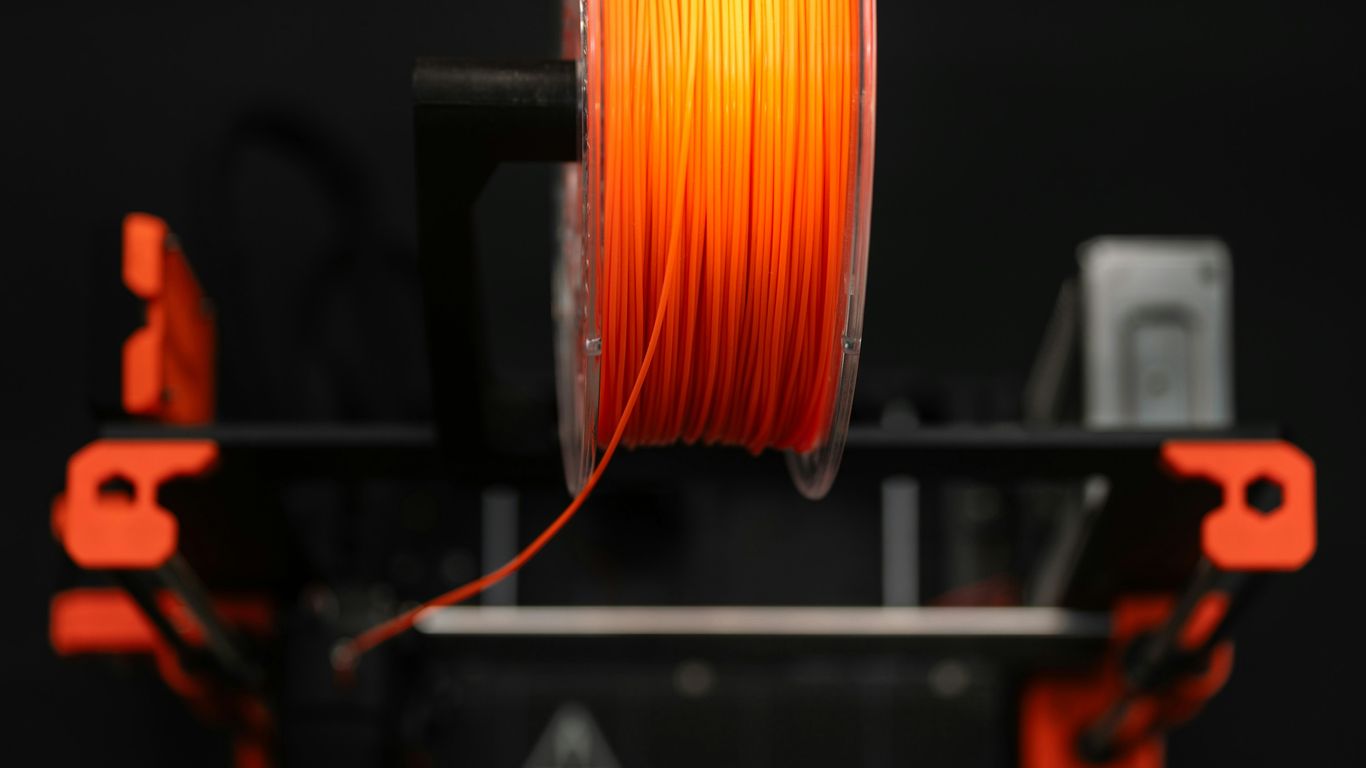

So, you’re getting into 3D printing, huh? It’s pretty cool stuff. You might be doing it just for fun, or maybe you’ve got a business idea brewing. Either way, one thing you might not have thought too much about yet is the actual material you’re printing with. It’s called filament, and there’s a bunch of different kinds. Figuring out what is the best 3D printing filament for what you want to make can feel a bit overwhelming at first. This article is here to break it down for you, looking at the common options and what they’re good for.

Key Takeaways

- PLA is a popular choice for beginners because it’s easy to print with and doesn’t smell bad. It’s good for general models and prototypes.

- ABS is tougher and more heat-resistant than PLA, making it suitable for parts that need to be strong or withstand higher temperatures, but it can be trickier to print.

- PETG offers a good middle ground, being strong, durable, and more temperature-resistant than PLA, while also being easier to print than ABS.

- ASA is similar to ABS but has better UV resistance, making it a good option for outdoor prints or parts exposed to sunlight.

- When choosing, think about what you’re printing, how strong it needs to be, and what your printer can handle. There’s no single ‘best’ filament for everyone.

1. Polylactic Acid (PLA)

When you first get into 3D printing, chances are you’ll be using PLA. It’s probably the most common material out there, and for good reason. It’s pretty easy to work with, doesn’t smell too bad when it’s printing, and it’s made from renewable resources like corn starch, which is a nice bonus if you’re thinking about the environment. PLA is a fantastic starting point for beginners and for general-purpose prints.

Think of PLA for things like decorative items, prototypes, or even toys. It holds its shape well and can capture fine details, making your prints look sharp. However, it’s not the toughest kid on the block. PLA can get a bit soft and warp if it gets too warm, so you probably don’t want to leave your PLA-printed mug in a hot car. It’s also a bit brittle, meaning it can snap if you bend it too much.

Here’s a quick rundown of what PLA is good for and what to watch out for:

- Pros:

- Easy to print, even for beginners.

- Made from renewable resources.

- Good for detailed prints.

- Low warping during printing.

- Cons:

- Low heat resistance (can warp above 60°C).

- Can be brittle and snap.

- Not ideal for functional parts that need to withstand stress or heat.

Most 1kg spools of PLA filament, typically 1.75mm in diameter, will give you around 333 meters (about 1092 feet) of material. This can vary slightly depending on the manufacturer, but it’s a good ballpark figure to keep in mind when you’re planning your prints and figuring out how much filament you’ll actually use.

2. Acrylonitrile Butadiene Styrene (ABS)

ABS, or Acrylonitrile Butadiene Styrene, is a common plastic that many 3D printing enthusiasts are familiar with. It’s known for being pretty tough and can handle a good amount of stress and impact, making it a solid choice for parts that need to be durable. Think functional prototypes or even parts that might get bumped around a bit.

One of the big advantages of ABS is its heat resistance. Unlike some other filaments, it doesn’t warp or deform as easily when exposed to higher temperatures. This makes it suitable for applications where the printed object might be near a heat source or used in a warmer environment. It also has a nice, smooth surface finish when printed correctly, which can look quite professional.

However, ABS isn’t without its quirks. Printing with it can be a bit trickier than, say, PLA. It tends to warp if the print bed isn’t heated properly, and it can release fumes that some people find unpleasant, so good ventilation is a must. You’ll often need an enclosure for your printer to keep the temperature stable around the print.

Here’s a quick rundown of what ABS brings to the table:

- Durability: It’s strong and can withstand impacts.

- Heat Resistance: It holds up better in warmer conditions.

- Post-Processing: It can be sanded and smoothed, and even chemically smoothed with acetone for a really slick finish.

- Warping Tendency: Requires a heated bed and often an enclosure to prevent prints from lifting.

- Fumes: Emits odors during printing, necessitating good ventilation.

So, if you need a print that’s tough, can handle some heat, and you’re prepared for a slightly more involved printing process, ABS is definitely worth considering.

3. Polyethylene Terephthalate Glycol (PETG)

PETG is a really popular choice for 3D printing, and for good reason. It kind of sits in the middle ground between PLA and ABS, offering some of the best qualities of both without all the fuss. It’s known for being tough and a bit flexible, making it great for parts that might take a hit or need to bend a little without snapping.

Think of it like this: PLA is easy to print but can be brittle. ABS is strong but can be tricky to print without a heated enclosure and can warp. PETG? It’s much easier to print than ABS, doesn’t usually warp as much, and it’s way more durable than PLA. This makes it a go-to for functional prints, mechanical parts, and even things that might be used outdoors because it holds up pretty well to moisture and UV light.

Here’s a quick rundown of why people like PETG:

- Durability: It’s strong and can withstand impacts better than PLA.

- Temperature Resistance: It can handle higher temperatures than PLA, though not as high as ABS or ASA.

- Ease of Printing: While it needs a bit more heat than PLA, it’s generally less prone to warping than ABS and doesn’t typically require a fully enclosed printer.

- Chemical Resistance: It’s resistant to many common chemicals, which is a plus for certain applications.

- Food Safety: Some PETG filaments are considered food-safe, but always check the manufacturer’s specifications if this is important for your project.

One thing to watch out for with PETG is that it can be a bit stringy if your print settings aren’t dialed in just right. You might need to play around with retraction settings and print speed to get those clean prints. Also, while it’s more rigid than some flexible filaments, it does have a bit of give, which can be a good thing for absorbing shock but might not be ideal if you need a super stiff part. It’s also a bit more prone to scratching than PLA, so if you’re printing something that needs a pristine surface finish, you might need to do some post-processing or consider a different material.

4. Acrylonitrile Styrene Acrylate (ASA)

Alright, let’s talk about ASA, or Acrylonitrile Styrene Acrylate. If you’ve been around 3D printing for a bit, you might have heard of ABS. ASA is kind of like its tougher, more weather-resistant cousin. It’s basically designed to handle the outdoors better than most other common filaments.

Think about it: you print something, and you want to put it outside. Maybe it’s a garden marker, a part for your car that sees sun and rain, or even just something sitting on a windowsill that gets a lot of light. PLA can get brittle and fade, and ABS can degrade when exposed to UV rays. That’s where ASA shines. It’s got this built-in resistance to sunlight and weather, so your prints are less likely to turn yellow or become weak over time.

It’s also pretty strong and can handle some heat, similar to ABS. This makes it a good choice for functional parts that might be used in less-than-ideal conditions. You’ll find it’s a bit trickier to print than PLA, often requiring an enclosure to keep the temperature stable and prevent warping, but the results are usually worth the effort.

Here’s a quick rundown of why you might pick ASA:

- UV Resistance: It doesn’t break down or discolor when exposed to sunlight.

- Weatherability: It holds up well against rain, wind, and temperature changes.

- Strength and Durability: It’s a tough material, good for parts that need to last.

- Heat Resistance: It can handle higher temperatures than PLA before softening.

When you’re printing with ASA, remember it can give off some fumes, so good ventilation is a must. It’s not quite as easy to print as PLA, but if your project needs to survive the elements, ASA is definitely a filament worth considering.

5. Metals

When we talk about 3D printing, metals might sound a bit out there, right? It’s not your everyday filament you’d find in a hobbyist’s printer, but it’s definitely a thing, and it’s pretty impressive. Think of things that need to be super strong and last a long time. We’re talking about printing with actual metals like steel, aluminum, or even titanium. This stuff is opening up doors in some really high-tech industries, like aerospace, where parts need to be incredibly reliable, or in the automotive world for custom components. Even in the medical field, they’re using it for things like implants.

The process for printing with metal is quite different from plastic. It usually involves specialized machines that use techniques like Selective Laser Sintering (SLS) or Metal Binder Jetting. These methods essentially fuse metal powder together, layer by layer, to build the final object. It’s a complex process, and the printers themselves are a significant investment, which is why you don’t see them in every home.

So, why would you even consider metal filament for 3D printing?

- Unmatched Strength and Durability: Metal prints can handle loads and stresses that plastics just can’t. This makes them ideal for functional parts, tools, or anything that needs to withstand wear and tear.

- High-Temperature Resistance: Unlike plastics that can warp or melt, metals can endure extreme temperatures, making them suitable for applications in hot environments.

- Aesthetic Appeal: Let’s be honest, metal just looks and feels premium. For things like custom jewelry, decorative pieces, or high-end prototypes, the metallic finish is a big draw.

- Complex Geometries: 3D printing allows for the creation of intricate metal parts that would be difficult or impossible to make with traditional manufacturing methods.

While it’s not for printing a simple trinket for your desk, if your project demands serious structural integrity, heat resistance, or a truly professional metallic look, exploring metal 3D printing is worth considering. It’s a fascinating area that’s constantly evolving, pushing the boundaries of what we can create. You can find more technical details about various 3D printing materials and their properties.

6. Paper

When you think about printing, paper is probably the first thing that pops into your head, right? It’s like the default setting for most print jobs. But honestly, there’s way more to paper than just, well, paper. It comes in all sorts of weights, textures, and finishes, and picking the right one can actually make a big difference in how your final print looks and feels.

Think about it: a fancy wedding invitation probably shouldn’t be printed on the same thin, cheap paper you’d use for a flyer handed out on the street. The paper sets the tone. For something like business cards or postcards, you’ll want something sturdier, maybe a thicker cardstock that feels substantial in your hand. On the flip side, if you’re printing a newspaper or a simple booklet, a lighter, more affordable paper makes more sense. The choice of paper really impacts the overall quality and perception of your printed material.

Here’s a quick rundown of some common paper types you might run into:

- Uncoated Paper: This is your basic, no-frills paper. It has a natural feel and is great for things you’ll be writing on, like stationery or notebooks. Colors might not pop as much, but it has a nice, matte look.

- Coated Paper: This paper has a special coating, giving it a smooth finish – either glossy or matte. It makes colors look super vibrant and images really sharp because the ink doesn’t soak in as much. Think brochures, magazines, or high-quality flyers.

- Cardstock: This is basically heavy-duty paper. It’s thick and durable, perfect for anything that needs to hold its shape and withstand a bit of handling, like business cards, postcards, or event invitations.

- Recycled Paper: If you’re trying to be a bit more eco-friendly, recycled paper is a solid choice. It’s made from post-consumer waste and comes in various weights and finishes, so you don’t have to sacrifice too much on quality.

7. Canvas

Canvas printing is a bit different from your typical paper print. Instead of a smooth surface, you get this nice, textured feel. It’s often used for artwork, like replicating paintings or printing designs that you want to have a more artistic, tactile quality. Think of it as giving your digital image a physical presence with a bit of character.

The texture of canvas can really make a print pop, especially for photographs or art pieces. It absorbs ink differently than paper, which can lead to a softer look, but also a richer depth for certain images. It’s not usually the go-to for everyday documents, but for something special, it’s a solid choice.

When you’re thinking about canvas prints, consider these points:

- Durability: Canvas prints can be quite durable, especially if they’re coated or protected. They hold up well to handling.

- Aesthetic: The woven texture gives a unique, gallery-like appearance that many people find appealing for decorative purposes.

- Ink Absorption: Because it’s a fabric, the ink soaks in a bit, which can affect the final color vibrancy compared to a glossy paper. This isn’t always a bad thing; it can create a more muted, artistic effect.

- Applications: Best suited for photographs, art reproductions, and decorative wall hangings. It’s less common for things like flyers or business cards.

8. Vinyl

When you need something tough that can handle the outdoors, vinyl is a material that often comes up. It’s not really for your typical desktop 3D printer, but it’s a big deal in the world of large-format printing and signage.

Think about those big banners you see at events, or the graphics on the side of a delivery truck. A lot of that is printed on vinyl. Why? Because it’s built to last.

Here’s what makes vinyl a good choice for certain jobs:

- Weather Resistance: Rain, sun, wind – vinyl can take it. It doesn’t easily fade or get damaged by the elements, which is a huge plus for anything that’s going to live outside.

- Durability: It’s a strong material that resists tearing and stretching, so your printed message stays looking good.

- Versatility: You can find vinyl in different finishes, like matte or glossy, and it adheres well to various surfaces, making it suitable for everything from simple stickers to complex vehicle wraps.

The main reason vinyl shines is its ability to withstand harsh conditions while keeping prints looking sharp. If your project needs to survive the great outdoors or endure a lot of handling, vinyl is definitely worth considering. It’s a workhorse material for signs, banners, and outdoor advertising where longevity is key.

9. Film

When you think about printing materials, film might not be the first thing that pops into your head, especially if you’re focused on typical home 3D printing. However, film plays a role in certain printing applications, often where transparency or a unique visual effect is needed. Think about things like backlit signs or graphics applied directly to glass surfaces. These often use specialized films.

These films are generally chosen for their ability to transmit or diffuse light, or for their smooth, non-porous surface. They aren’t typically used in standard FDM or resin 3D printers you’d find at home. Instead, they are more common in industrial printing processes or for creating specific display elements. The exact type of film used can vary a lot depending on the intended use, but common examples include polyester or vinyl-based films. If you’re looking for materials that offer a different kind of visual output than solid plastics, exploring specialty printing films might be interesting, though it’s a bit outside the usual 3D printing filament discussion. For more on common 3D printing filaments, you can check out various 3D printing filaments.

10. Reusable Filament Spools

So, you’ve been 3D printing for a while, and you’ve noticed all those empty plastic spools piling up. It’s a bit of a bummer, right? Well, there’s a growing trend to cut down on that waste: reusable filament spools. These are designed so you can buy just the filament refill and wind it onto a spool you already own. It’s a pretty neat idea for reducing plastic waste and, honestly, it can save you some space too.

The big advantage here is cutting down on single-use plastic.

If you’re thinking about printing your own reusable spool, there’s a really important detail to remember: don’t use PLA. Seriously, don’t do it. PLA can warp and deform when it gets warm, like during filament drying. You really want to use something tougher, like ASA or PETG, which can handle the heat much better. ASA is super durable and holds up well to temperature, while PETG offers a good mix of being flexible and tough.

Even with PETG, though, DIY spools can sometimes be a bit finicky. Sometimes, filament refills aren’t wound perfectly, and they can snag on the edges of a printed spool. This is where a well-made, commercially produced reusable spool can make a difference. They’re often designed with tighter tolerances and more robust connections to prevent these kinds of issues. For example, some have threaded connections that keep them from coming apart, even when you’re printing for a long time. It means less wobble and no chance of filament spilling everywhere.

Here are a few things to keep in mind:

- Material Choice is Key: If you’re printing your own, stick to heat-resistant materials like ASA or PETG. PLA is a no-go for spools.

- Refill Winding Matters: Not all filament refills are wound perfectly. Some can be a bit loose or off-center, which can cause problems on DIY spools.

- Bundles Can Save Money: Often, buying a reusable spool bundled with filament is cheaper than buying them separately. It’s worth checking out these deals.

- Don’t Swap Mid-Roll: Unless the spool is completely empty, leave the filament on it. Trying to swap filaments halfway through can lead to a tangled mess.

When you’re looking at reusable spools, check out options that are made from sturdy materials like ABS, which are built to last. They should be easy to put together and compatible with most filament refills you find. It’s a small change, but it really helps with the environmental impact of 3D printing material sourcing.

So, What’s the Verdict?

Alright, so we’ve talked about a bunch of different filaments, right? From the easy-going PLA to the tougher ABS and PETG. It’s not really about one being the ‘best’ for everyone. It really just depends on what you’re trying to make. If you’re just starting out or making display stuff, PLA is probably your go-to. Need something stronger that won’t warp when it gets a little warm? PETG or ASA might be better. Think about what your print needs to do after it’s off the printer. Does it need to bend? Withstand heat? Just look cool on a shelf? Figuring that out is half the battle. Don’t forget about your printer too; make sure it can handle the material you pick. It’s all about matching the filament to your project, your printer, and your budget. Happy printing!