We’re all hearing more about biomass energy these days, right? With the world looking for alternatives to fossil fuels, biomass is popping up as a potential player. It’s basically energy from plants and organic stuff. Sounds pretty straightforward, but like anything, it’s got its ups and downs. This article is going to break down the good and the not-so-good about using biomass for energy, looking at what makes it attractive and what hurdles we still need to clear.

Key Takeaways

- Biomass energy comes from organic materials like plants and waste, offering a renewable alternative to fossil fuels.

- A major plus is its renewable nature and potential for carbon neutrality, as plants absorb CO2 while growing.

- However, biomass often has a low energy density, meaning you need a lot of it to get a significant amount of energy.

- Collecting, transporting, and dealing with inconsistent biomass sources can be costly and complicated.

- Various conversion methods exist, like pyrolysis and gasification, turning biomass into useful fuels and heat, but technology and economics are still developing.

Understanding Biomass Energy Advantages

So, let’s talk about why biomass energy is getting so much attention. It’s basically energy from organic stuff – plants, wood, even waste. And honestly, it’s got some pretty good points going for it, especially when you compare it to digging up fossil fuels.

Renewable Resource Potential

First off, biomass is renewable. That’s a big deal. Unlike coal or oil, which we’re burning through at an alarming rate, we can actually grow more plants. Think trees, crops, or even agricultural leftovers. As long as we’re smart about how we harvest and replant, we’ve got a pretty steady supply. It’s not like we’re going to run out of trees next year. This makes it a much more sustainable option for the long haul. We’re talking about a resource that can replenish itself, which is a pretty neat trick.

Carbon Neutrality Benefits

Then there’s the whole carbon thing. Plants absorb carbon dioxide (CO2) from the air as they grow. When we burn biomass for energy, it releases that CO2 back. But, because new plants are growing and taking up CO2 again, the net effect is supposed to be neutral. It’s like a closed loop. This is a huge contrast to fossil fuels, which release old carbon that’s been locked away for millions of years, adding extra CO2 to the atmosphere. So, using biomass can help keep our carbon footprint from getting any bigger. It’s a way to use energy without adding to the problem of excess greenhouse gases.

Abundance and Distribution

Another plus is that biomass is pretty much everywhere. You’ve got agricultural waste from farms, wood scraps from forests, and even garbage from cities. This means that biomass resources aren’t just concentrated in a few spots around the globe. Many communities can tap into local biomass sources for their energy needs. This can lead to more energy independence and reduce the need for long, expensive transportation of fuels. It’s a decentralized energy solution that can work in a lot of different places. Here’s a quick look at some common sources:

- Agricultural Residues (e.g., corn stalks, straw)

- Forestry Residues (e.g., wood chips, bark)

- Energy Crops (e.g., switchgrass, poplar)

- Organic Municipal Solid Waste (e.g., food scraps)

- Animal Manure

Exploring Biomass Energy Disadvantages

While biomass energy sounds pretty great on paper, especially with all the talk about renewable resources and carbon neutrality, it’s not without its own set of headaches. We can’t just pretend these issues don’t exist if we’re serious about using biomass.

Low Energy Density Challenges

One of the biggest hurdles is that biomass just doesn’t pack as much energy per pound or per volume as fossil fuels like coal or oil. Think about it – a truckload of wood chips has a lot less usable energy than a truckload of coal. This means you need a whole lot more biomass to get the same amount of heat or electricity. It’s like trying to fill up your car with water instead of gasoline; you’d need a massive tank and a lot of water to go the same distance.

Collection and Transportation Costs

Because biomass is spread out and less energy-dense, getting it from where it’s grown or produced to where it’s going to be used can get really expensive. You’re dealing with bulky materials, often from rural areas. This involves harvesting, collecting, and then hauling it, sometimes over long distances. All that fuel for trucks, the labor, and the equipment add up fast. It’s a logistical puzzle that can eat into any cost savings you might expect from using a renewable fuel.

Feedstock Inconsistencies

Biomass isn’t like a standardized product. The stuff you get from agricultural waste one season might be different from the next, or different from forestry residue. This variation in moisture content, chemical composition, and physical form can really mess with the conversion process. Imagine trying to cook a recipe where the ingredients change wildly every time you make it – sometimes you get a great meal, other times it’s a disaster. This inconsistency makes it tough to design and operate conversion facilities that run smoothly and predictably. You often need extra steps to prepare the feedstock, like drying or sorting, which adds more cost and complexity.

Thermochemical Conversion Pathways

So, how do we actually turn all that plant stuff into usable energy? That’s where thermochemical conversion comes in. Basically, it’s about using heat to break down biomass into different forms of energy or useful materials. Think of it like cooking, but for energy production. There are a few main ways we do this, and each has its own quirks and best uses.

Pyrolysis for Bio-oil and Gas

Pyrolysis is like baking biomass in an oven with very little or no oxygen. When you heat it up, it breaks down into three main things: a liquid called bio-oil, a gas, and a solid char. The bio-oil can be further processed into fuels or chemicals. The gas can be burned for heat, and the char is a carbon-rich solid that can be used as a soil amendment or even for filtering.

- Produces a liquid fuel (bio-oil) that’s easier to transport than solid biomass.

- Can handle a variety of feedstocks, making it pretty flexible.

- The char byproduct has potential uses, which is a nice bonus.

Gasification for Syngas Production

Gasification is a bit more intense. We heat biomass with a limited amount of oxygen or steam. This process converts the biomass into a "syngas" – a mix mostly of hydrogen and carbon monoxide. This syngas is super versatile. You can burn it directly for heat and electricity, or you can use it as a building block to create other fuels and chemicals, like methanol or synthetic natural gas. It’s a really adaptable process for making different kinds of energy products.

- Syngas can be used for electricity, heat, or to make other fuels.

- Can handle larger-scale operations.

- Requires careful control of temperature and gasifying agent.

Combustion for Direct Heat and Power

This is probably the most straightforward method. Combustion is just burning biomass, plain and simple. You burn it, and the heat produced can be used directly for heating buildings or industrial processes. You can also use that heat to boil water, create steam, and then use that steam to spin a turbine and generate electricity. It’s the most common way biomass is used for energy right now, especially for large power plants.

- Directly converts biomass to heat and electricity.

- Relatively simple technology.

- Emissions need to be managed carefully, just like with burning fossil fuels.

Technological Advancements in Biomass Utilization

So, we’ve talked about the good and the bad of biomass energy. Now, let’s get into how we’re actually making it work better. It’s not just about burning stuff anymore; there’s some pretty neat tech coming into play.

Role of Artificial Intelligence in Optimization

Think about trying to get the most out of your biomass. It’s complicated, right? You’ve got different types of plant matter, varying moisture levels, and all sorts of ways to process it. Artificial intelligence (AI) is starting to make a real difference here. Instead of endless trial and error, AI can look at huge amounts of data – like what kind of biomass you have, the temperature, pressure, and other settings – and predict the best way to get the most useful products, whether that’s bio-oil, gas, or char. It helps researchers and companies figure out the sweet spot for operating conditions without wasting time and resources on experiments that might not work.

Mechanical Pretreatment for Efficiency

Biomass, especially stuff like wood chips or straw, can be tough to break down. It’s like trying to digest a whole salad versus a smoothie. Mechanical pretreatment is all about making that biomass easier to process. This can involve things like grinding it up really fine, or using steam to soften it. The goal is to increase the surface area and make the complex molecules inside more accessible for the next steps, like conversion into fuel. It’s a bit like prepping your ingredients before you start cooking – makes the whole process smoother and more effective.

Reactor Design and Commercialization

Finally, getting these processes out of the lab and into the real world is a huge step. This is where reactor design comes in. Engineers are constantly working on building better "kitchens" – the reactors – where biomass gets converted. They’re designing them to be more efficient, safer, and able to handle larger amounts of material. This includes everything from small-scale units for local communities to massive industrial plants. The aim is to make biomass energy not just a good idea on paper, but a practical and affordable reality for more people.

Economic and Environmental Considerations

When we talk about biomass energy, it’s not just about the science; we’ve got to look at the money and the planet, too. It’s a balancing act, really.

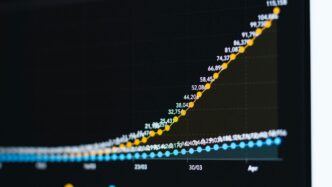

Techno-economic Analysis for Viability

Figuring out if biomass energy makes financial sense is a big deal. We need to look at all the costs involved, from collecting the stuff to turning it into usable energy. Right now, fossil fuels are still pretty cheap, so biomass has to work hard to compete. Making bio-oil cost-effective is key for it to really take off. This means finding ways to use different kinds of biomass, making the most of any byproducts, and improving the processes to lower costs and make the final fuel better. It’s also super important to have systems that can handle the fact that biomass isn’t always the same – one load might be wetter or different than the next. Setting some standards for things like moisture content could really help smooth things out.

Waste Valorization and Circular Economy

This is where biomass energy gets really interesting. Instead of just throwing things away, we can turn waste into something useful. Think about agricultural leftovers, wood scraps, or even stuff from our garbage. Turning these into energy fits right into the idea of a circular economy, where we reuse and recycle as much as possible. It’s about getting value out of things we’d otherwise consider trash. This approach can help reduce landfill waste and create new revenue streams.

Environmental Impact Mitigation

While biomass is often seen as greener, it’s not without its environmental footprint. We need to be smart about how we manage it. This involves:

- Sustainable Sourcing: Making sure we’re not cutting down forests faster than they can grow or using up land that could be used for food.

- Emission Controls: Even though biomass can be carbon neutral, burning it still releases pollutants. We need good technology to clean up those emissions.

- Land Use Planning: Carefully considering where biomass crops are grown to avoid negative impacts on local ecosystems and biodiversity.

- Water Management: Being mindful of water usage during cultivation and processing, especially in drier regions.

Getting these aspects right means biomass energy can be a truly sustainable option, but it requires careful planning and ongoing monitoring.

So, What’s the Verdict on Biomass Energy?

Alright, so we’ve looked at biomass energy, and it’s definitely not a simple black-and-white issue. On one hand, it’s renewable, uses waste materials, and can be a good way to cut down on greenhouse gases. That’s pretty big stuff. But then you have the other side of the coin: it can be tricky to collect and process, sometimes it doesn’t pack as much punch energy-wise as fossil fuels, and getting it to work efficiently on a large scale still has its hurdles. It feels like we’re still figuring out the best ways to make it work smoothly and affordably. While it’s a promising piece of the puzzle for a greener future, there’s still work to be done to iron out the kinks and make it a truly mainstream energy source. It’s a tool in the toolbox, for sure, but maybe not the only tool we need.