Weighing things seems simple, right? Just put it on the scale and see what it says. But when you start looking at the technology behind it all, things get more interesting. We’ve got these old-school mechanical scales and then the fancy digital ones. Each has its own good points and bad points, and figuring out which is best for what job can be kind of a puzzle. Let’s break down the advantages and disadvantages technology brings to the table when it comes to weighing.

Key Takeaways

- Digital scales offer speed and easy-to-use features like programmable settings, but they need electricity and can be tricky in rough places.

- Mechanical scales are tough and simple, great for tough spots, but they aren’t always super precise and can be slow to read.

- Smart body composition scales give you more than just weight, showing body fat and muscle, and can track your progress over time, though they cost more and the info can be confusing.

- Choosing between digital and mechanical scales really depends on what you need – accuracy and automation for digital, or simple toughness for mechanical.

- When thinking about cost, remember that while digital scales might cost more upfront, they can save money long-term with less upkeep and better efficiency.

Understanding The Advantages And Disadvantages Of Technology

Technology, especially in the realm of weighing, has really changed things. It’s not just about knowing if you’re a few pounds heavier or lighter anymore. We’re talking about scales that do way more than they used to, and that’s both good and, well, sometimes a bit much.

Efficiency And Speed Of Digital Scales

Digital scales are generally quicker. Think about a busy warehouse or a lab where every second counts. These scales often have a faster response time, meaning you get a reading almost instantly. This speed is a big deal when you’re dealing with a lot of items or need to keep things moving. Plus, they’re usually pretty straightforward to use. You don’t need a degree to figure out how to put something on them and get a number. This efficiency can really speed up workflows.

User-Friendly Interfaces And Accessibility

Many digital scales come with clear displays and simple buttons. This makes them accessible to a lot of people, even if they aren’t super tech-savvy. Some even have features like multilingual displays, which is handy if you have a diverse team working with them. It means fewer mistakes and less confusion, which is always a win.

Programmable Settings And Multilingual Displays

This is where digital scales really shine for specific jobs. You can often program them for different tasks, like taring out containers or setting weight limits. And those multilingual displays? They’re not just a gimmick; they genuinely help in places where people speak different languages. It makes using the equipment much easier and safer for everyone involved.

Navigating The Drawbacks Of Digital Weighing Technology

While digital scales are pretty amazing for a lot of things, they aren’t perfect. You know, like how your phone is great until the battery dies? Digital scales have a similar issue. They need electricity to work, which can be a real pain if the power goes out. That’s the biggest hurdle, really. If you’re in a place with unreliable power, or maybe you’re out in a field somewhere, a digital scale might just sit there uselessly.

Then there’s the whole durability thing. These scales have delicate electronics inside. If you’re using them in a dusty workshop, a steamy kitchen, or somewhere it gets really cold or hot, those parts can get damaged. It’s not like a sturdy old mechanical scale that can take a beating. You have to be a bit more careful with digital ones, especially if your work environment isn’t exactly clean and climate-controlled.

And when something does go wrong? Fixing them can be a headache. It’s not usually a simple fix like tightening a screw. You might need a specialist, or at least someone who knows their way around circuit boards. This can mean more downtime and, let’s be honest, more money spent on repairs. It’s a trade-off for all that fancy digital accuracy, I guess.

Here are a few things to keep in mind:

- Power Dependency: They won’t work without electricity. Battery-powered models help, but batteries run out too.

- Environmental Sensitivity: Dust, moisture, and extreme temperatures can cause problems.

- Repair Complexity: Fixing them often requires specialized knowledge and parts.

- Cost of Maintenance: While often accurate, repairs can be more expensive than for simpler mechanical scales.

Suitability For Different Industries

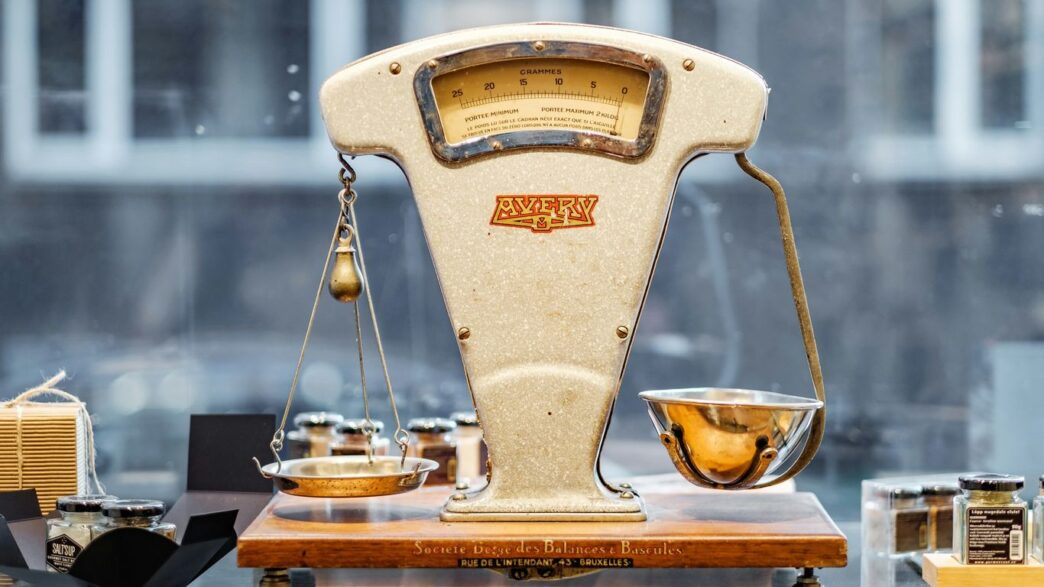

Mechanical Scales For Durability And Simplicity

When you need something tough and straightforward, mechanical scales really shine. Think about places like busy workshops or outdoor sites where electronics might get fussy. These scales don’t need power, so they’re great where electricity is spotty or just not available. They’re built to take a beating and keep on working, which is a big plus when you’re dealing with rough conditions. They use simple parts like springs and levers, making them pretty easy to figure out and keep running. You won’t find yourself wrestling with complicated manuals or needing a tech wizard to fix them.

Digital Scales For High Accuracy And Integration

On the other hand, digital scales are the go-to for jobs that demand super precise measurements. Industries like pharmaceuticals, where even a tiny bit off can cause big problems, rely on them. They’re also fantastic for connecting with other computer systems. Imagine a warehouse where scales automatically tell inventory software how much product you have – that’s digital scales at work. They can handle a lot of data and speed up processes, which is a lifesaver when you’re trying to get things done quickly and without mistakes. Plus, their displays are usually clear and easy to read, showing numbers right away.

Specialized Scales For Unique Industry Needs

Beyond the basic mechanical and digital types, there’s a whole world of specialized scales designed for very specific jobs. For example, in agriculture, special livestock scales help farmers keep track of animal weight for health and growth monitoring. In factories, bench scales are used for weighing, checking quantities, and even counting small parts quickly, which is a huge time-saver during packaging. And in labs, you’ve got precision balances and analytical balances that can measure incredibly tiny amounts, absolutely vital for scientific research and making medicines. These specialized tools are built to solve particular problems, making sure that whatever your industry, there’s a scale that can do the job right.

The Pros Of Digital Platform Scales

When you’re looking at weighing things, especially in a business or industrial setting, digital platform scales really stand out. They’ve pretty much replaced the old mechanical ones for a lot of jobs, and for good reason. The biggest win is how much more accurate they are.

High Accuracy And Precision

Digital platform scales use electronic load cells. Think of these as super sensitive sensors that measure the force applied to them. Because they’re electronic, they can pick up on tiny changes in weight that a mechanical scale would just miss. This means you get readings that are much closer to the real weight, down to fractions of a pound or even less. This level of precision is a game-changer for things like:

- Mixing ingredients where exact ratios matter.

- Shipping and receiving where every ounce counts for billing.

- Quality control to make sure products meet specific weight standards.

Unlike mechanical scales with their moving parts that can wear out or get dirty, causing errors, digital scales offer a more consistent and reliable measurement over time. They’re built to handle a lot, too, with capacities that can go way up, from a few hundred pounds to many thousands.

Automation And Integration Capabilities

This is where digital scales really shine compared to their older counterparts. They’re not just for weighing anymore; they’re smart. Most digital platform scales can connect to computers or other systems. This means:

- Data can be automatically recorded: No more scribbling down numbers by hand, which saves time and cuts down on mistakes. The scale can send the weight data straight to inventory software or a production log.

- Integration with other equipment: They can be part of a larger automated process. For example, a scale could signal a conveyor belt to stop once a certain weight is reached, or trigger a filling machine.

- Remote monitoring: In some setups, you don’t even need to be right next to the scale to see the reading or control it. You can often check it from a computer screen elsewhere.

This ability to connect and automate makes operations much smoother and faster, especially in busy environments.

Ultra Precision With Advanced Technology

For jobs that need the absolute highest level of accuracy, there’s even more advanced tech available. Some digital platform scales use special designs, like multiple load cells placed strategically under the platform. This setup helps distribute the weight evenly and reduces errors from where you place the item on the scale. There’s also technology that uses special surface acoustic waves (SAW) to measure weight. This is a patented method that offers an incredible level of precision, far beyond what standard digital scales can achieve. If your work demands measurements that are extremely exact, down to the tiniest fraction, these advanced digital scales are the way to go. They can handle the most demanding applications where even a minuscule error is unacceptable.

Limitations Of Mechanical Weighing Scales

Mechanical scales, while sturdy and reliable in many ways, do come with their own set of drawbacks that are worth considering. They’ve been around forever, using springs and levers to figure out weight, and that old-school approach means they just can’t keep up with modern demands in some areas.

Precision Challenges With Light Or Heavy Objects

One of the main issues is accuracy, especially when you’re dealing with things at the extreme ends of the weight spectrum. Measuring something super light can be tricky because the slightest bit of friction in the mechanism, or even a tiny vibration, can throw off the reading. It’s like trying to balance a feather on a wobbly table. On the flip side, really heavy loads can sometimes put too much stress on those same moving parts, leading to wear and tear that also messes with precision over time. It’s not uncommon for mechanical scales to have a margin of error that’s just too big for today’s sensitive applications. Think about needing to measure ingredients down to the gram for a pharmaceutical product; a mechanical scale would likely struggle to give you that level of detail consistently.

Complex Calibration And Regular Maintenance Needs

Keeping a mechanical scale accurate isn’t a set-it-and-forget-it kind of deal. These things need regular attention. The pivots, bearings, and linkages can get dirty or worn out, and that means they need cleaning and adjusting. Calibration, which is making sure the scale reads correctly, often involves fiddling with weights and making manual adjustments. This isn’t a quick process, and if it’s not done often enough, the scale’s readings will start to drift. It’s a bit like maintaining an old car; it runs, but it needs constant tinkering to keep it running right. This can add up in terms of time and labor costs, especially if you have a lot of scales to manage.

Slower Response Times And Reading Difficulties

When you put something on a mechanical scale, you often have to wait for the needle or pointer to settle down before you can get a reading. This can be a real drag in busy environments where you need to weigh a lot of items quickly. Imagine a shipping dock where packages are constantly coming through; waiting for each scale reading to stabilize would create a huge bottleneck. Plus, reading the dial itself can be a pain. Depending on the angle you’re looking from, or the clarity of the markings, you might misread the weight. It’s easy to make a mistake, especially if the dial has fine increments or if the lighting isn’t great. This human element adds another layer of potential error that digital scales largely avoid with their clear, digital readouts.

Advantages Of Smart Body Composition Scales

So, you’re thinking about getting a new scale, huh? Forget those old-school ones that just tell you how much you weigh. Smart body composition scales are a whole different ballgame. They give you a much more detailed look at what’s actually going on inside your body.

These aren’t just for serious athletes, either. If you’re trying to get healthier, lose some fat, or build muscle, these scales can be super helpful. They use a little trick called bioelectrical impedance analysis. Basically, a tiny, safe electrical current runs through your body. Different tissues, like fat and muscle, mess with that current in different ways, and the scale figures it out from there.

Detailed Insights Beyond Simple Weight Measurement

This is where things get interesting. Instead of just one number, you get a whole report card for your body. You can see things like:

- Body Fat Percentage: How much of your weight is actually fat.

- Muscle Mass: How much muscle you’re carrying.

- Body Water: Your hydration levels.

- Bone Mass: The weight of your bones.

- BMI: Your Body Mass Index.

Seeing these numbers can be way more motivating than just watching the pounds go up or down. For example, you might be losing weight, but if your muscle mass is going up and your fat percentage is going down, that’s a win! It shows you’re getting fitter, not just lighter.

Tracking Progress Over Time With Connectivity

This is the ‘smart’ part. Most of these scales connect to an app on your phone, usually through Bluetooth or Wi-Fi. Every time you step on the scale, your measurements get sent straight to the app. This means you get a history of all your readings. You can look back and see how your body fat has changed over weeks or months. It’s like having a personal health journal that updates itself. This makes it way easier to spot trends and see if what you’re doing with your diet and exercise is actually working.

Multiple User Profiles For Family Use

Got a family? No problem. These scales usually let you set up different profiles for everyone. So, you and your partner, or even your kids, can all use the same scale and keep your measurements separate. Each person gets their own data tracked in the app. It’s pretty neat for keeping everyone accountable and on track with their own health goals without mixing up the numbers. It makes it a useful tool for the whole household, really.

Cost Considerations For Weighing Technology

When you’re looking at weighing scales, it’s easy to just focus on the price tag. But honestly, there’s a lot more to think about than just the initial cost. You’ve got to consider the whole picture, from how much it costs to buy it to what it’ll cost to keep it running over the years.

Initial Investment Versus Long-Term Savings

Mechanical scales often seem cheaper upfront. They don’t have fancy electronics, so the sticker price can be lower. But, and this is a big ‘but’, they tend to need more upkeep. Think regular check-ups, replacing parts that wear out, especially if you’re using them a lot in a busy workshop or factory. Digital scales, on the other hand, might cost more when you first buy them. That’s because they have all that advanced tech built-in. However, they usually need less maintenance. Plus, features like automation can actually save you money down the line by cutting down on labor and mistakes. It’s a classic case of paying a bit more now to save a lot later. A good cost-benefit analysis can really help you see which option makes more financial sense for your specific situation.

Ongoing Maintenance And Calibration Expenses

This is where the costs can really add up, no matter what kind of scale you have. Mechanical scales might need frequent calibration to stay accurate, and if a spring or lever breaks, that’s another repair bill. Digital scales generally hold their calibration better, but they still need to be checked periodically. If a load cell goes bad or the display glitches, that’s a repair cost too. It’s important to factor in these regular expenses when budgeting for your weighing equipment. Some scales might need calibration every few months, while others can go a year or more.

Streamlining Operations Through Automation

This is a big one, especially for businesses. Digital scales can often connect to computers or other systems. This means you can automate tasks like recording weights, calculating totals, or even controlling other processes based on the weight. Imagine a production line where the scale automatically tells a machine to stop adding ingredients once the right weight is reached. That kind of automation can seriously cut down on manual labor, reduce errors that happen when people are doing repetitive tasks, and speed up your whole operation. While setting up these automated systems can have an upfront cost, the efficiency gains and labor savings can be huge over time. It’s about making your weighing process work smarter, not just harder.

Wrapping It Up

So, we’ve looked at how technology can be a real game-changer, making things faster and giving us more details than ever before. Think about how much easier it is to track progress or get precise measurements now. But, it’s not all smooth sailing. Sometimes, these gadgets need power, can be tricky to figure out, and let’s be honest, they can cost a pretty penny. It really comes down to what you need. For some jobs, simple and tough is best. For others, all those fancy digital features are a must. The key is to pick the right tool for the job, weighing what you gain against what you might give up. It’s all about finding that balance that works for you.

Frequently Asked Questions

What makes digital scales faster than old-fashioned ones?

Digital scales use electronic parts that react super quickly to weight. Think of it like a light switch that turns on instantly, compared to a dimmer switch that takes a moment to adjust. This speed is great when you need to weigh a lot of things fast.

Can digital scales break easily if I drop them or use them in a dusty place?

Sometimes, yes. Because they have delicate electronic parts, digital scales can be sensitive to rough handling or dusty, wet, or very hot places. Mechanical scales, with fewer moving parts, might handle tough environments better.

Do I need electricity for all digital scales to work?

Most digital scales need electricity to power their sensors and displays. However, many modern ones come with rechargeable batteries, so you can still use them even if there’s no power outlet nearby. Some very basic mechanical scales don’t need any power at all.

Are mechanical scales always less accurate than digital ones?

Generally, digital scales offer higher accuracy and precision, especially for very light or very heavy items. Mechanical scales can sometimes struggle with exact measurements and might need more frequent checking and adjusting to stay accurate.

What’s the big deal with smart body composition scales?

These aren’t just for weighing! Smart scales can also tell you about your body fat, muscle mass, and more. They connect to your phone to track your progress over time, which can be super motivating for fitness goals.

Is it cheaper to buy a mechanical scale or a digital scale?

Mechanical scales often cost less to buy at first. But, digital scales, even though they might cost more upfront, can save you money in the long run because they usually need less maintenance and last longer. Plus, their smart features can make work faster and reduce mistakes.