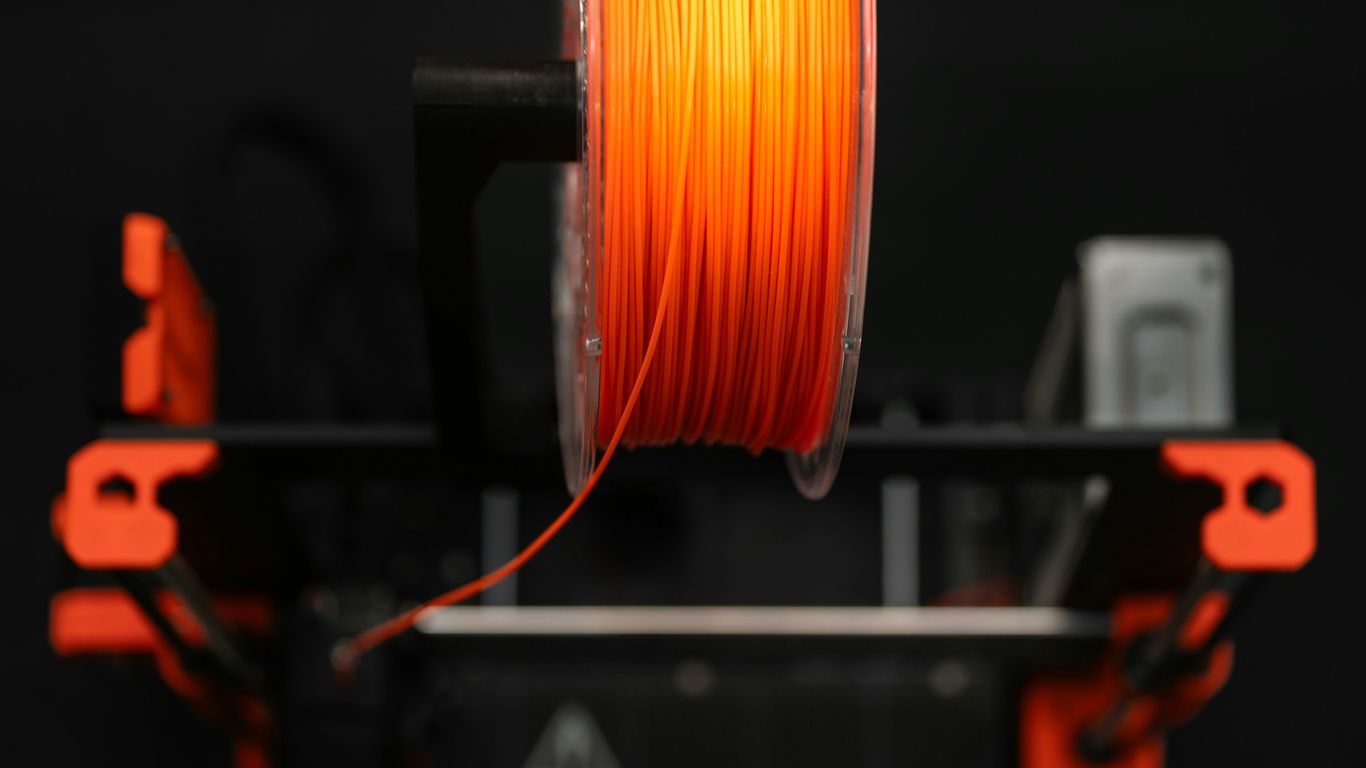

So, you’re wondering why 3D printing is becoming the go-to for making stuff these days, especially when you compare it to the old reliable, injection molding. It’s not like injection molding is going anywhere, but 3D printing has really stepped up its game. Think about it: making complicated shapes, getting exactly what you want without a huge upfront cost, and getting your ideas into your hands way faster. We’re going to break down why this modern method is shaking things up in manufacturing.

Key Takeaways

- 3D printing lets you create really intricate designs and custom parts without needing expensive molds, which injection molding requires.

- For small batches or one-off items, 3D printing is usually cheaper to get started with and much faster than setting up for injection molding.

- You can get prototypes and new products made much quicker with 3D printing because you skip the long mold-making process.

- While injection molding has a huge range of materials, 3D printing is catching up fast and offers specialized options for specific needs.

- 3D printing is great for making exactly what you need when you need it, reducing material waste compared to traditional methods that cut away material.

Unlocking Design Freedom: Why 3D Printing Excels

When you’re trying to make something new, especially if it’s a bit complicated, 3D printing really shines. Unlike older methods that need specific tools for every little shape, 3D printing just builds things up layer by layer. This means you’re not stuck with what a mold can do.

Complex Geometries Made Possible

Think about parts with lots of internal structures, curves that look almost organic, or really thin walls. Injection molding struggles with these. You’d need a super complex, expensive mold, and even then, it might not work perfectly. 3D printing, though? It handles these intricate designs without breaking a sweat. Because it adds material precisely where it’s needed, it can create shapes that would be impossible or incredibly difficult with traditional methods. It’s like the difference between carving a statue from a block of marble versus building one up with tiny bricks – you have way more control over the final form with the latter.

Customization Without Tooling Constraints

Need a part that’s slightly different from the last one? Or maybe you want to make a bunch of unique items, like personalized medical devices or custom car parts? With injection molding, changing the design means making a whole new mold, which costs a lot and takes time. 3D printing bypasses this entirely. You just tweak the digital file, and the printer makes the new version. This makes it super easy to create one-off pieces or small batches of customized items without any extra tooling costs. It really opens up possibilities for products that need to fit individuals perfectly.

Rapid Iteration For Product Development

Getting a product just right often takes a few tries. You make a prototype, test it, find a problem, fix it, and then make another. This cycle is way faster with 3D printing. You can go from a digital design to a physical part in hours or days, not weeks or months. If you spot an issue, you can adjust the design and print a new version almost immediately. This ability to quickly test and refine designs means you can get your product to market much faster and with fewer headaches. It’s a game-changer for innovation because it lowers the risk and cost of trying out new ideas.

Cost-Effectiveness For Modern Production Needs

When we talk about making things, especially in today’s world, how much it costs upfront and for each piece really matters. This is where 3D printing starts to shine, especially when you compare it to older methods like injection molding.

Lower Upfront Investment

Think about injection molding. You need to create a custom metal mold, and that can cost a lot of money – we’re talking thousands, sometimes tens of thousands of dollars. Plus, it takes a good chunk of time to get that mold made. With 3D printing, you don’t need a mold at all. You send your digital design straight to the printer, and it starts building your part. This means you can start making things with very little money spent before you even print the first item. It’s a huge difference, especially for small businesses or people just starting out with a new product idea.

Economical For Low-Volume Runs

Because there’s no expensive tooling to pay for, 3D printing is way more affordable when you only need a few items. If you need, say, 50 or 100 parts, using injection molding would mean spreading that huge mold cost over those few parts, making each one really expensive. 3D printing, on the other hand, just charges you for the material and the print time. This makes it perfect for:

- Limited edition products

- Specialized components for niche markets

- Testing the waters with a new product before committing to mass production

Reduced Tooling Expenses

This ties into the first two points, but it’s worth repeating. The cost and time associated with creating and maintaining molds for injection molding are significant. If you need to make a change to your product design after the mold is made, you’re looking at another big expense and delay to get a new mold. 3D printing bypasses this entirely. You just tweak the digital file and print a new version. This flexibility saves a ton of money and headaches, especially during the product development phase where changes are common.

Accelerating Time To Market

One of the biggest headaches in getting a new product out the door is the sheer amount of time it takes. Traditional manufacturing methods, like injection molding, often involve really long lead times. Think about it: you have to design a mold, get it made, test it, and then finally start production. This whole process can take months, sometimes even longer. 3D printing completely bypasses this lengthy mold fabrication step.

With additive manufacturing, you can go straight from a digital design to a physical part. This means you can start producing items almost immediately after the design is finalized. This is a game-changer for product development cycles. Instead of waiting weeks or months for a mold, you can have prototypes or even small production runs ready in days or hours. This speed allows for much faster iteration, letting you test designs, gather feedback, and make improvements without significant delays.

Here’s a quick look at how the timelines compare:

| Process | Typical Time to First Part | Notes |

|---|---|---|

| Injection Molding | Weeks to Months | Includes mold design and fabrication |

| 3D Printing | Hours to Days | Direct from digital file to physical part |

This on-demand production capability means you don’t need to stockpile inventory months in advance. You can print what you need, when you need it. This flexibility is incredibly useful for startups and companies looking to test new markets or offer customized products. It really helps bridge the gap between having an idea and actually selling it, making the whole journey from concept to customer much quicker. For high-volume production, injection molding is the preferred method. However, additive manufacturing (3D printing) excels in situations requiring agility, intricate designs, rapid turnaround, and cost-effectiveness for smaller production runs [fc5c].

Material Versatility And Application

When we talk about manufacturing, the materials you can use really matter. It’s not just about what something is made of, but how that material choice affects what you can actually build and where it can go. 3D printing has really opened up a lot of doors here.

Expanding Material Options

Unlike older methods that might be limited to a few types of plastics or metals, 3D printing can work with a much wider range. We’re seeing everything from standard thermoplastics and tough resins to advanced ceramics, flexible elastomers, and even metal powders. This means you’re not stuck with just one or two choices. You can pick a material that’s just right for the job, whether that’s something super strong, something that bends, or something that can handle high heat.

Tailoring Properties For Specific Uses

This variety in materials isn’t just for show. It lets manufacturers get really specific about what a part needs to do. For example, if you need a component for a car that has to withstand a lot of vibration, you can choose a specific polymer blend designed for that. Or in the medical field, you might need a biocompatible material for an implant that also has a certain level of flexibility. 3D printing makes it possible to fine-tune these properties without needing a whole new manufacturing setup.

Functional End-Use Parts

What’s really changing the game is that 3D printing isn’t just for making prototypes anymore. We’re now seeing parts printed that are actually used in the final product, out in the real world. Think about aerospace components that need to be lightweight but incredibly strong, or custom tools for specific industrial tasks. The ability to print with high-performance materials means that 3D printed parts can meet the demanding requirements of end-use applications, often performing just as well as, or even better than, parts made with traditional methods.

Streamlining Production Processes

When we talk about making things, there are generally two main ways to go about it: building things up or taking things away. 3D printing falls into the first category, known as additive manufacturing. Think of it like building with LEGOs, but on a much more precise level. You start with nothing and add material, layer by layer, exactly where it’s needed, based on a digital blueprint. This is a big change from older methods like subtractive manufacturing, where you start with a block of material and carve away the bits you don’t need. That’s how a lot of traditional machining works.

Additive Versus Subtractive Manufacturing

This difference in approach has some pretty big implications. With additive manufacturing (3D printing), you’re not wasting material by cutting it away. You’re essentially using only what you need for the final part. This can be a huge win for efficiency and reducing scrap. Plus, because you’re building from the ground up, you can create shapes that would be incredibly difficult, if not impossible, to make with subtractive methods. Imagine intricate internal channels or complex organic forms – 3D printing handles these with relative ease.

Layer-By-Layer Precision

The magic of 3D printing really happens in how it builds things. Each layer is laid down with incredible accuracy, following the digital design down to the micron. This layer-by-layer precision means you can achieve very detailed and complex geometries without needing specialized tools for every single curve or angle. It’s like having a super-smart robot that can draw your object in 3D, one thin slice at a time. This level of control is what allows for the customization and intricate designs we talked about earlier.

Reduced Waste Through Material Efficiency

Let’s circle back to that waste point. Because 3D printing only adds material where it’s needed, it’s inherently more material-efficient than subtractive processes. This isn’t just good for your bottom line; it’s also better for the environment. Less material used means less raw material extraction and less waste to dispose of. While some materials might be more expensive upfront, the overall reduction in waste can make a significant difference, especially for complex parts where subtractive methods would create a lot of leftover material.

Addressing Production Volume Demands

Ideal For Small Batch Manufacturing

When you’re just starting out, or maybe you’ve got a niche product, making a few hundred or even a thousand units makes sense. This is where 3D printing really shines. You don’t need to spend a fortune on a giant mold that’s only going to be used a handful of times. You can print what you need, when you need it. This flexibility means you’re not stuck with a ton of inventory if demand is lower than expected. Plus, if you need to tweak the design based on early customer feedback, it’s way easier and cheaper to adjust a 3D print file than to retool an entire injection mold.

Scalability Challenges For Mass Production

Now, if you’re talking about making millions of parts, injection molding is still the king. 3D printing, while getting faster, can be slow when you need to produce a massive quantity. Imagine trying to print a million identical phone cases one by one – it would take ages! Setting up a 3D printing farm with hundreds of machines could work, but the cost and complexity can quickly add up, potentially making it more expensive per part than traditional methods for very large runs. It’s a different ballgame when you’re aiming for that kind of volume.

Bridging The Gap To High-Volume Needs

So, what’s the solution when you need more than a few hundred parts, but maybe not millions? This is where things get interesting. 3D printing can be fantastic for creating the initial molds or tooling that are then used in smaller-scale injection molding processes. Think of it as a stepping stone. You can use 3D printing to quickly produce a custom mold, run a limited batch of parts using that mold, and then, if demand really takes off, you can invest in a more permanent, high-volume injection mold. This hybrid approach lets you test the market and scale up gradually, reducing risk and getting your product out there faster without committing to massive upfront costs for tooling that might not be needed.

Wrapping It Up

So, when you look at it all, 3D printing really shines for a lot of modern needs. It’s not about replacing injection molding entirely, but it’s definitely a game-changer for getting ideas made fast, especially when you need custom parts or just a few items. The ability to tweak designs on the fly and avoid huge upfront costs makes it super practical for businesses trying to innovate or just get a product out the door quickly. While injection molding still has its place for massive production runs, 3D printing offers a flexibility and speed that’s hard to beat for many projects today.