The RS-68A Engine’s Genesis and Design

So, the RS-68A. It didn’t just pop into existence. Its story really starts back in the early 90s when Rocketdyne decided it was time to build a new big rocket engine for the US, something that hadn’t happened in ages. They came up with the RS-68, which ended up being chosen for the Delta EELVs.

Evolution from the RS-68

The RS-68 itself was pretty impressive. It was, and still is, the biggest liquid hydrogen and liquid oxygen engine out there. Think of it as a straightforward, bell-shaped booster engine. It could push out about 650,000 pounds of thrust right at sea level. That’s like 17 million horsepower, which is a wild amount of power. It used a simple open gas generator cycle and had a regeneratively cooled main chamber. Pretty neat stuff for its time.

Simplified Design Philosophy

What really set the RS-68 apart, and by extension the RS-68A, was its design approach. The goal was simplicity. Fewer parts mean lower costs and easier manufacturing. The original RS-68 had only 11 major components. Compare that to the Space Shuttle Main Engine (SSME), which had way more parts – like 80% fewer in the RS-68. This meant a lot less hand labor, faster development, and significantly lower upfront costs. This focus on a streamlined design made it a more practical choice for certain applications.

Key Components of the RS-68A

While the RS-68A is an evolution, it keeps that core simplified philosophy. You’ve got the main combustion chamber where all the action happens, single turbopumps for both the liquid oxygen and liquid hydrogen, a gas generator to power those pumps, and heat exchangers to manage temperatures. The design aims for reliability and ease of use, building on the lessons learned from earlier engines. It’s a robust piece of engineering designed to get the job done without unnecessary complexity.

Power and Performance Metrics

Thrust Capabilities

The RS-68A engine is a real powerhouse, designed to generate some serious push. It’s built to provide a substantial amount of thrust, which is pretty important for getting heavy payloads off the ground and into space. Think of it as the muscle behind the launch. While the exact numbers can vary a bit depending on the specific mission profile and operating conditions, this engine is engineered for high-thrust applications.

Specific Impulse and Mixture Ratio

When we talk about how efficient a rocket engine is, we often look at its specific impulse, or Isp. This basically tells you how much thrust you get for a certain amount of propellant consumed over time. A higher Isp means you’re getting more bang for your buck, propellant-wise. The RS-68A uses a mixture ratio, which is the ratio of oxidizer to fuel, that’s optimized for its performance goals. Getting this ratio just right is key to maximizing both thrust and efficiency. It’s a delicate balance that engineers spend a lot of time fine-tuning.

Engine Thrust-to-Weight Ratio

Another big deal for rocket engines is their thrust-to-weight ratio, often shortened to T/W. This metric compares the engine’s thrust output to its own weight. A higher T/W ratio means the engine is lighter for the amount of force it can produce. This is super important because every bit of weight saved on the engine means you can carry more payload or use less fuel. The RS-68A aims for a competitive T/W ratio, making it a strong contender for various launch vehicle designs.

Development and Testing of the RS-68A

Lessons Learned from Previous Engines

When developing the RS-68A, Aerojet Rocketdyne really leaned on what they learned from earlier engine projects. Think of the Space Shuttle Main Engine (SSME) – it was the first reusable rocket engine to actually fly, and there were tons of lessons from its development and upgrades. Engineers looked closely at how the SSME was built and maintained, and how it performed. This knowledge was super helpful when designing new engines like the RS-68A, aiming for something simpler and more reliable. They also looked at programs like the RS-83 and RS-84, which were also designed with reusability and easier maintenance in mind. It’s all about not repeating past mistakes and building on what worked.

Advanced Design Tools and Modeling

Back in the day, designing rocket engines was a lot of trial and error, which is expensive. Rocketdyne, now part of Aerojet Rocketdyne, put a big effort into using better computer tools. They focused on things like computational fluid dynamics (CFD) and thermal modeling. Using these advanced design tools helped them cut down development costs significantly, even for the earlier RS-68 engine. They figured that if they could keep their skilled people and these tools, they could save even more money on future engine projects. The goal was to get a much clearer picture of how the engine would perform before ever building a physical part.

Ground Demonstrator Engine Testing

To really nail down the performance and reliability of new engine designs, testing is a must. Aerojet Rocketdyne made it a priority to test advanced components using ground demonstrator engines. This approach helps identify and reduce risks early on. For the RS-68A program, they focused on a few key areas that were considered high-risk. These included making sure materials could handle hydrogen well, improving how the turbine parts worked, testing a smaller version of the liquid preburner, and making sure the electronic controls were solid. This hands-on testing, even before the full engine was ready, was a big part of making sure the RS-68A would perform as expected.

Comparison with Other Rocket Engines

When we look at the RS-68A, it’s helpful to see how it stacks up against some other big names in rocket propulsion. It’s not just about raw power, but also efficiency, design choices, and what they were built for.

RS-68A vs. SSME

The Space Shuttle Main Engine (SSME), now known as the RS-25, was a marvel of its time, designed for reusability and high performance. It used liquid hydrogen (LH2) and liquid oxygen (LOX) and had a complex full-flow staged combustion cycle. This gave it incredible specific impulse (Isp), meaning it was very efficient with its fuel. However, that complexity came with a high cost and a more involved maintenance routine.

The RS-68A, on the other hand, uses a simpler gas-generator cycle and, importantly, liquid oxygen and liquid hydrogen (LOX/LH2). While its Isp isn’t quite as high as the SSME’s, it produces significantly more thrust, making it a powerhouse for lifting heavy payloads. Think of it as a heavy-duty truck compared to a high-performance sports car. The RS-68A’s design also aimed for easier manufacturing and maintenance.

Here’s a quick look at some numbers:

| Characteristic | RS-68A (Delta IV) | SSME (RS-25) |

|---|---|---|

| Thrust (sea level) | 3,560 kN (800,000 lbf) | 2,280 kN (510,000 lbf) |

| Isp (vacuum) | 414 s | 453 s |

| Propellants | LOX/LH2 | LOX/LH2 |

| Cycle | Gas Generator | Full-Flow Staged Comb. |

| Engine T/W (sea level) | 51 | 73.12 |

RS-68A vs. RS-83

The RS-83 was another engine concept that aimed to improve upon existing designs. It was intended to be simpler to build and maintain than the SSME, using a fuel-rich preburner in its staged combustion cycle. It also used LOX/LH2.

Compared to the RS-68A, the RS-83 was designed for a different role, potentially as a booster engine. While the RS-68A is known for its massive thrust output for the Delta IV launch system, the RS-83 was envisioned with a focus on reliability and ease of operation. The RS-83’s design included features like accessible turbopumps and components made with powder metallurgy, aiming for a good balance between performance and manufacturability. It’s interesting to see how different design philosophies can lead to engines suited for slightly different missions, much like how different vehicles are designed for various tasks, from carrying passengers to hauling cargo.

RS-68A vs. RS-84

The RS-84 was an interesting project because it explored using RP-1 (kerosene) and LOX as propellants, unlike the RS-68A and SSME which use LOX/LH2. This choice has some significant implications. Kerosene is denser than liquid hydrogen, meaning you need smaller fuel tanks for the same amount of energy. It’s also not cryogenic, which simplifies ground operations and reduces the need for heavy insulation on fuel lines and tanks. This can lead to lower costs and faster turnaround times between launches.

However, liquid hydrogen, despite its handling challenges, offers a higher specific impulse. The RS-83 and SSME, using LH2, achieved higher vacuum Isp values. The RS-84 was designed to produce a very large amount of thrust, even more than the RS-68A in some configurations, making it a contender for heavy-lift boosters. The RS-68A, with its LOX/LH2 combination and gas-generator cycle, strikes a balance, providing substantial thrust with good efficiency for its intended role on the Delta IV family of rockets.

Aerojet Rocketdyne’s Propulsion Innovations

Focus on Liquid Propulsion

Aerojet Rocketdyne has put a lot of effort into making liquid rocket engines better. They’ve been working on things like upper-stage engine technology, aiming to create design tools that are based on actual physics rather than just past experiences. This helps them build better components, like turbopumps for hydrogen, which are needed for future rockets. They’re also looking into new materials, like liquid crystal polymers, to make parts lighter and cheaper for these demanding cryogenic engines. It’s all about pushing the boundaries of what liquid engines can do.

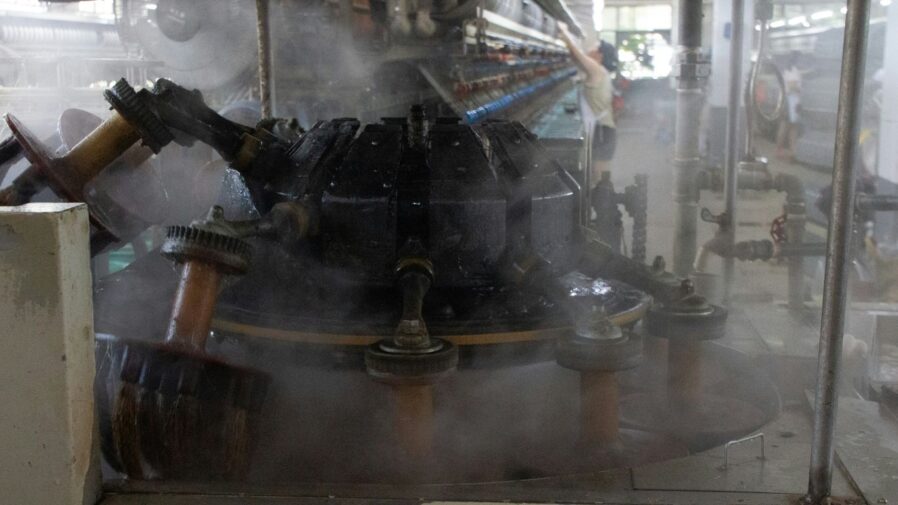

Advancements in Turbomachinery

When it comes to the heart of a rocket engine, the turbopumps are pretty important. Aerojet Rocketdyne has spent years developing hydrostatic bearings for these. These bearings are different from the usual rolling ones and can handle more coolant flow and last longer. They’ve tested them, but there’s still more work to do before they’re ready for actual flights. Beyond bearings, they’re also working on ways to stop turbine blades from vibrating too much, which can cause them to break. Plus, they’re exploring stronger materials for the parts that spin fast, which could let smaller turbopumps run even quicker. It’s a lot of detailed work to make these complex parts more reliable and efficient.

Health Management Systems

While not directly related to the RS-68A’s core function, Aerojet Rocketdyne also invests in systems that monitor the health of rocket engines. This involves developing ways to predict and prevent problems before they happen. Think of it like a car’s diagnostic system, but for rockets. By using advanced sensors and data analysis, they can keep an eye on how the engine is performing during operation. This helps ensure missions go smoothly and can also provide valuable information for future engine designs. This proactive approach to engine monitoring is key to improving overall mission success and reliability.

Wrapping Up the RS-68A

So, after looking at all this, it’s pretty clear the RS-68A is a big deal in rocket engines. It’s a powerful piece of tech that’s been put through its paces. They really focused on making it simpler and cheaper to build compared to older engines, which makes a lot of sense for getting things into space more often. It’s not just about raw power, but also about smart design and making sure it works reliably. The testing and upgrades show a real effort to keep improving it, even as space flight changes. It’s a solid engine that’s played a key role in getting rockets off the ground.