Semiconductors are everywhere these days, powering everything from our phones to hospitals and cars. While a lot of attention goes to where chips are made, how they’re actually invented is a big deal too. Companies spend tons of money on research to keep making them better. This article looks at the latest ideas from a big event called IEDM, which is a major spot for semiconductor innovation.

Key Takeaways

- IEDM is a major conference where new semiconductor technologies are shown off, covering everything from how chips are made to how they work.

- New ways of designing chips, like Design Technology Co-Optimization (DTCO), are important because simply making things smaller isn’t enough anymore.

- Future chip designs are exploring things like putting power lines on the back of the chip to make them work better and be more efficient.

- Countries like China, South Korea, and Taiwan are doing more and more research in semiconductors, not just manufacturing them.

- International teamwork is becoming really important in semiconductor research because the challenges are so big, with US and European researchers collaborating more.

IEDM: A Hub for Semiconductor Innovation

The International Electron Devices Meeting, or IEDM as it’s commonly known, is a pretty big deal in the world of semiconductors. Think of it as the yearly get-together where all the latest breakthroughs and future ideas in chip technology get shared. It’s not just about the shiny new gadgets; it’s about the deep science and engineering that makes them possible.

Understanding the Scope of IEDM

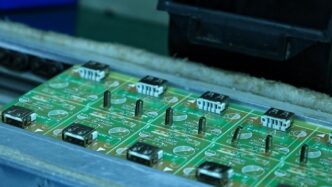

IEDM covers a massive range of topics. We’re talking everything from the basic physics of how new electronic devices work, to the actual design of those devices, and then all the way through to how they’re manufactured. It’s a place where researchers present their work on new materials, novel device structures, and advanced manufacturing techniques. Basically, if it’s a significant step forward in semiconductor technology, you’ll likely hear about it at IEDM. It really spans the entire semiconductor value chain, from the initial concept to the final product.

Historical Significance of IEDM

This conference has been around since 1955, which means it’s seen some pretty incredible shifts in technology. Early on, it was likely focused on vacuum tubes and early transistors. Over the decades, it’s tracked the progress of integrated circuits, microprocessors, and all the innovations that led to the powerful devices we use today. It’s a living history book of semiconductor advancement. Being there means being at the forefront of what’s next, building on decades of progress.

IEDM’s Role in the Semiconductor Value Chain

IEDM isn’t just an academic conference; it has a real impact on the industry. Companies and research institutions use the information shared at IEDM to guide their own R&D efforts. The discussions and papers presented can influence the direction of future chip development, from the materials used to the architectures designed. It’s a place where ideas are exchanged, collaborations are sparked, and the roadmap for the next generation of semiconductors is often sketched out. It’s a key event for anyone involved in pushing the boundaries of what’s possible with silicon, and it’s a great place to see how different parts of the industry connect, much like how Virgin Galactic is pushing boundaries in space tourism Sir Richard Branson has unveiled Virgin Galactic’s new spaceship.

Here’s a look at the kind of topics you might find discussed:

- New transistor designs for better performance and lower power consumption.

- Innovations in memory technologies, like faster and denser storage.

- Advancements in packaging and interconnects to link chips together more efficiently.

- Exploration of new materials beyond silicon to overcome current limitations.

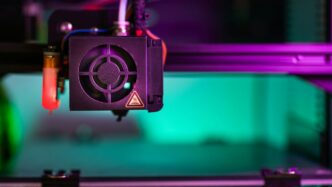

Advancements in Process Technology

The way we design and build chips is really changing. It’s not just about making things smaller anymore; it’s about smarter integration and new ways to get power where it needs to go. This is where things like Design Technology Co-Optimization, or DTCO, come into play. Basically, chip designers and process engineers are working together much more closely now. Instead of just handing off rules, they’re figuring out how to tweak the manufacturing process itself to make the designs better, often allowing for more compact standard cells. This is super important because just shrinking things down, like we used to with Moore’s Law, isn’t cutting it like it used to.

One big hurdle we’re facing is with vias, those little connections between layers. Copper is great because it doesn’t resist electricity much, but you need a barrier layer, usually something like tantalum nitride (TaN), to stop it from spreading. The problem is, this barrier takes up space, shrinking the copper’s usable area, and it adds its own resistance. So, even though copper is good, the barrier makes the via less ideal. This is a constant battle to find better materials or ways to minimize the barrier’s impact. Some research is even looking at materials that could let light travel at near-infinite speeds on a chip, which sounds wild but could totally change how we connect things faster-than-light speeds on a microchip.

We’re also seeing a lot of work on new device architectures, especially for power delivery. Think about backside power delivery networks (BS-PDN). The idea is to put the power lines on the back of the chip, separate from the signal wires on the front. This can cut down on signal interference and make the chip area more efficient. There are a few ways to do this:

- TSV-Middle: Here, power is right next to the active transistors and shared between cells. The backside metal 1 (BSM1) lines up with the active areas.

- Buried Power Rail (BPR): Power is built into the chip next to the active transistors. Special connections tap into these buried rails, and the buried rail essentially takes over the job of the backside metal 1.

- Backside Contact: Power is placed directly under the active transistors, with vias connecting to these rails, and BSM1 aligned with the gate.

Each of these has its own set of challenges. For instance, getting the backside aligned perfectly with the frontside is incredibly tricky, needing precision down to about 10 nanometers. Also, making these backside power connections often requires thinning the wafer down to less than 10 micrometers, which is a delicate process. For buried power rails, materials like tungsten (W) and ruthenium (Ru) are being considered. Tungsten is easier to work with and less likely to cause contamination, but ruthenium, especially without a barrier, might offer even lower resistance. It’s a complex puzzle of materials and precision manufacturing.

Exploring Future Device Architectures

So, what’s next for how we build these tiny brains? IEDM always gives us a peek into the future, and this year, a lot of talk is about rethinking where we put the power delivery. You know, the stuff that actually makes the chips run.

Backside Power Delivery Networks

This is a pretty big deal. Instead of running power lines on the same side of the wafer as the actual processing bits, we’re looking at putting them on the back. Why? Well, it frees up space on the front for more logic, which means more performance. Plus, it can help manage the heat and power flow better, especially with how much power these chips are starting to use. Think of it like giving your computer a dedicated power cord that doesn’t get tangled up with everything else. Some folks are even talking about putting other components, like capacitors, on the backside too. It’s still early days, but the idea is to make things more efficient.

TSV-Middle Architectures

This is one way to do the backside power thing. Basically, the power lines run right next to the active parts of the chip, and they’re shared between different sections. It’s a bit like having a shared highway for power. The challenge here is making sure everything lines up perfectly. We’re talking about aligning things down to the nanometer scale, which is incredibly precise. It also means the wafer needs to be super thin, like less than 10 micrometers. To handle that, they often bond a support wafer to the main one before grinding it down. It’s a complex process, for sure.

Buried Power Rail Innovations

Another approach is to bury the power lines right next to the active components, but on the front side of the wafer. So, instead of going all the way to the back, some of the power infrastructure is integrated more closely. This method uses what they call ‘buried power rails’ (BPRs). The big question with these buried rails is what material to use. Tungsten is a strong contender because it’s less likely to cause contamination issues and meets the resistance targets. But then there’s Ruthenium, which, if done right without a barrier, might offer even lower resistance. It’s a trade-off, and the industry is still figuring out the best path forward. The goal is to get more power where it’s needed, without messing up the signal.

Global R&D Powerhouses in Semiconductors

US and Japan’s Historical R&D Contributions

For a long time, the United States and Japan were the undisputed leaders in semiconductor research and development. Back in the 1990s, Japan held a massive chunk of the global chip market, around 49%. This dominance was mirrored in their research output, with Japan contributing a significant 40% of research papers in the mid-90s. The US has also consistently been a major player, driving innovation through its universities and private companies. These historical contributions laid much of the groundwork for the technologies we rely on today.

Rising R&D Influence of Asian Nations

Things have shifted quite a bit over the last decade or so. We’re seeing a big jump in research activity coming from countries like China, South Korea, and Taiwan. It’s not just about manufacturing anymore; these nations are deeply involved in creating the next generation of chips. For instance, China’s research paper contributions have grown substantially, now surpassing those of countries like Belgium. South Korea and Taiwan, already key manufacturing hubs, are also pouring resources into R&D, with their companies and research groups actively publishing at major conferences.

Here’s a look at the changing landscape in terms of research paper contributions to leading semiconductor conferences:

| Country/Region | Share in 2014 | Share in 2020 |

|---|---|---|

| China | 5% | Significantly Increased |

| South Korea | 8.8% | Significantly Increased |

| Taiwan | 13% | Significantly Increased |

The Importance of International Collaboration

While it’s interesting to see which countries are leading in R&D, it’s also important to remember that semiconductor development is a global effort. The sheer cost and complexity of developing new chip technologies mean that collaboration is key. Countries that might have seen their market share drop, like Japan, still have valuable knowledge and experience. Likewise, regions like Europe, with strong research institutions, contribute significantly to the R&D landscape even if their market share isn’t as high. This interconnectedness highlights why international cooperation is so vital for pushing the boundaries of what’s possible in semiconductor technology.

Key Technological Challenges and Solutions

So, we’ve talked about some of the cool new ways chips are being designed, but it’s not all smooth sailing. There are some pretty big hurdles the industry is trying to jump over.

Addressing Wafer Thinning Requirements

One of the main issues, especially with things like backside power delivery, is how thin the silicon wafers need to be. We’re talking less than 10 micrometers. To even get close to that, companies have to bond a support wafer to the main one before they start grinding it down. It’s a delicate process, and getting it right is a big deal for making these advanced designs work.

Frontside to Backside Alignment Precision

Then there’s the alignment. Imagine trying to line up microscopic features on the front of a wafer with features on the back. For things like nano-through-silicon vias (nTSVs), the precision needed is around 10 nanometers. That’s incredibly tight, and any slight misalignment can cause big problems. It’s like trying to thread a needle while wearing mittens – really, really difficult.

Material Choices for Power Rails

When you’re building these new power delivery networks, the materials you use for the power rails matter a lot. For buried power rails, tungsten and ruthenium are the main contenders. Tungsten is good because it doesn’t contaminate things as much and can hit the resistance targets. But ruthenium, especially without a barrier layer, seems to offer lower resistance in the vias. Finding that sweet spot between resistance, manufacturability, and reliability is key. It’s a constant balancing act, and the choices made here can really impact chip performance. This is where innovations in material science really come into play, helping to amplify each charged particle from a source into thousands of charge carriers, which could open up new applications in electronics [56f4].

These challenges aren’t small, but the progress being made at conferences like IEDM shows that the industry is actively working on solutions. It’s a complex puzzle, but one that’s vital for the future of semiconductors.

The Evolving Landscape of Semiconductor Research

Impact of Policy on R&D Investment

Governments around the world are really pushing for more semiconductor manufacturing, which makes sense given how much it costs to build new factories. But focusing only on where chips are made misses a big part of the picture. The actual technology inside those chips, the stuff that makes them faster and more efficient, comes from a ton of research. Companies are spending a lot, like over 18% of their revenue on R&D, just to keep up. Recent policies in places like the US and Europe are trying to boost manufacturing, but we can’t forget that research is what really shapes what chips will be like in the future. It’s not just about having the factories; it’s about who’s designing the next big thing. This balance between manufacturing and research investment is something policymakers are still figuring out.

The Growing Role of Research Institutions

It’s not just big companies doing all the heavy lifting in semiconductor research anymore. Universities and research centers are stepping up their game. They’re publishing more papers and collaborating on new ideas. This is super important because the pace of innovation is so fast. It takes way more people working together now than it did back in the 70s to keep up with things like Moore’s Law. So, having these institutions involved is key to tackling the big technical hurdles we face.

Lessons from Global Semiconductor Market Shifts

We’ve seen some big changes in who’s leading the pack in semiconductor research over the last couple of decades. The US has always been strong, but countries in Asia, especially China, South Korea, and Taiwan, have become major players. They’re not just manufacturing hubs anymore; they’re actively involved in developing future chip technologies. For instance, companies like TSMC in Taiwan and Samsung in South Korea are investing heavily in R&D, often working with others. This shift shows how important it is for countries to invest in research if they want to stay competitive. It also highlights how much international collaboration has grown. Back in the 90s, US research was mostly domestic, but now a big chunk involves international partners. This global teamwork is pretty much the only way we’re going to solve the really tough problems ahead in chip development. It’s like how the new iPager is making communication easier, but it took a lot of different people and ideas to get it made obsev.

Here’s a quick look at how research contributions have shifted:

| Country/Region | 2014 Share | 2020 Share |

|---|---|---|

| China | 5% | ~13% |

| South Korea | 8.8% | ~15% |

| Taiwan | 13% | ~18% |

Wrapping Up: What’s Next for Semiconductors?

So, after looking at all the cool stuff presented at IEDM, it’s clear the world of semiconductors is always moving. We saw talks about new ways to get power to chips, which sounds pretty wild, and also how designing chips and the manufacturing process have to go hand-in-hand now. It’s not just about making things smaller anymore; it’s about finding clever ways to make them work better and use less energy. It really makes you think about how much research goes into these tiny components we all rely on. Countries like China, South Korea, and Taiwan are really stepping up their game in research, not just manufacturing. It’s a reminder that while we talk a lot about where chips are made, who’s actually inventing the next big thing is just as important. It’ll be interesting to see how all these advancements play out.

Frequently Asked Questions

What is IEDM and why is it important for chip technology?

IEDM, or the International Electron Devices Meeting, is a big yearly event where scientists and engineers show off the newest ideas and inventions in computer chips and electronic devices. It’s like a showcase for the future of technology, covering everything from how chips are made to how they work and how they’re designed. It’s a key place to see what’s next in the world of semiconductors.

What is ‘Design Technology Co-Optimization’ (DTCO)?

DTCO is a modern way of making chips where the design of the chip and the methods used to build it are planned together from the start. Instead of just giving designers rules, the people who make the chips work closely with the designers to find clever ways to improve how chips are made and how well they work, especially as chips get smaller and more complex.

What are some new ideas for how chips are built in the future?

New ways to build chips are being explored, like putting power lines on the back of the chip instead of the front. This helps make chips smaller and work better. Other ideas include using special tunnels called TSVs or burying power lines right next to the working parts of the chip to improve how power gets to them.

Which countries are leading the way in chip research?

While countries like the US and Japan have a long history of leading in chip research, countries like China, South Korea, and Taiwan have become very important in recent years. They are not just making a lot of chips but are also doing a lot of the research and development to create the next generation of chip technology.

What are the main difficulties in making advanced chips?

Making the smallest and best chips today faces several hurdles. One big problem is making sure the tiny connections, called vias, don’t add too much resistance, which slows down the chip. Another challenge is precisely lining up different parts of the chip, especially when working on both the front and back sides, and finding the right materials for new designs.

Why is research and development (R&D) so important for semiconductors?

The chip industry needs constant innovation to keep improving. Even though governments are focusing on building more factories, research is crucial for creating more energy-efficient, sustainable, and powerful chips. Companies spend a lot of money on R&D because it’s the key to staying ahead and solving tough technical problems, ensuring we have the advanced chips needed for everything from phones to cars.