Aerospace labs are changing how we think about flight and space travel. These labs are not just for scientists in white coats—they’re where new ideas turn into real planes, rockets, and satellites. Whether it’s making air travel less polluting or building rockets that can be used again and again, aerospace labs are setting the pace for what’s possible in the 21st century. Here’s what’s happening right now and why it matters.

Key Takeaways

- Aerospace labs are leading the charge in making aviation cleaner and more efficient, from electric planes to new fuels.

- Reusable rockets and smaller satellites are making space exploration cheaper and more accessible for everyone.

- Defense projects in aerospace labs are focused on faster, smarter, and more autonomous systems, including drones and hypersonic tech.

- Digital tools like AI and robotics are helping aerospace labs build, maintain, and operate aircraft and spacecraft with fewer mistakes and less downtime.

- Working together—across companies, governments, and universities—helps aerospace labs push boundaries faster and solve bigger problems.

Aerospace Labs Driving Sustainable Aviation

In the last decade or so, there’s been a big shift in what aviation companies care about. It’s not just about getting somewhere fast anymore; it’s about getting there with a lot less pollution. Aerospace labs all over the globe are focusing hard on making planes cleaner, quieter, and way more efficient.

Electrification of Aircraft Fleets

A lot of research groups and big companies are now looking at electric airplanes. Some planes are already flying on short hops using only batteries. The whole idea is to ditch fossil fuels as much as possible and use electricity, either stored in batteries or generated with hydrogen fuel cells. Here’s what’s happening:

- Prototype electric planes are flying test routes, especially for regional trips.

- Hybrid systems are being developed to combine batteries with regular jet engines.

- Startups and industry giants are racing to build bigger electric aircraft.

One neat side effect is that electric motors are super quiet, which could make city airports a lot less noisy. But, battery weight is still a challenge, especially for bigger planes.

Sustainable Aviation Fuels in Practice

Sustainable Aviation Fuel (SAF) has gone from an idea to something used in commercial jets today. SAF is made from things like used cooking oil, plant waste, or even algae. It looks a lot like regular jet fuel, but it can slash carbon emissions—sometimes by as much as 80% over its lifecycle. Worldwide, Sustainable Aviation Fuel innovation is growing fast, especially in North America and Europe thanks to newer labs and test facilities.

Table: SAF vs Traditional Jet Fuel

| Fuel Type | Feedstock | CO2 Emissions (%) | Used in Commercial Flights? |

|---|---|---|---|

| Traditional Jet Fuel | Crude Oil | 100 | Yes |

| Sustainable Fuel | Plant/Organic Waste | 20–40 | Yes |

Advanced Aerodynamic Designs

There’s a lot of experimenting with new airplane shapes these days. Researchers are playing with things like blended wing-body designs, tapered tails, and even wings that can change shape a bit in flight. The end goal is more lift, less drag, and less fuel burned. Here are three recent focuses:

- Drawing up planes with smoother lines to cut air resistance.

- Testing morphing wings that flex to adapt to different flying conditions.

- Adding winglets and other tweaks to squeeze every bit of efficiency out of current designs.

Lightweight Composite Materials

If a plane weighs less, it doesn’t need as much energy to fly. So, labs are working with new materials—think strong plastics mixed with fibers like carbon or glass. Swapping out heavy metal for these light composites means better fuel efficiency and sometimes even more durability.

Key points about these materials:

- Carbon fiber composites are replacing older aluminum panels.

- Parts made from composites can be shaped for better aerodynamics.

- Maintenance costs can drop because some of these materials don’t rust.

Thanks to all this research happening in aerospace labs, the whole industry is accelerating toward a cleaner, quieter, and more efficient future.

Revolutionizing Space Exploration Through Aerospace Labs

Aerospace labs are quickly changing how we think about space travel and business. Innovative research is bringing down costs and making it possible for more people, and more types of companies, to participate in the space industry. Let’s look at what’s driving these changes.

Reusable Rocket Technologies

Back in the day, rockets were basically single-use—launched once and junked after the mission. That made space missions expensive and limited how often we could launch. Now, labs are focused on making rockets that you can land, reuse, and refuel. Reusable launch systems are cutting the cost of space access dramatically. Just think about how often SpaceX’s Falcon 9 boosters are launched, landed, and used again. It’s almost becoming routine. Here are some big shifts:

- Private companies are competing to recover rockets safely.

- Turnaround times between launches are dropping every year.

- The focus is on making space travel more like air travel: frequent and affordable.

| Feature | Single-Use Rockets | Reusable Rockets |

|---|---|---|

| Cost per Launch | $100M+ | $30M-$60M |

| Maximum Flights per Unit | 1 | 10+ |

| Environmental Impact | High | Lower |

CubeSats and Satellite Miniaturization

It used to take years and billions to build and launch traditional satellites. Now, mini-satellites like CubeSats are changing the game. These small, modular satellites fit inside a breadbox but can do things that only huge satellites managed before. Labs are working on new ways to build and launch these quickly.

Some key advantages:

- Fast development cycles

- Lower launch costs (as CubeSats hitch rides on rockets headed for bigger missions)

- Flexibility for companies and universities to run experiments or commercialize new services

This shift means more types of organizations can join in—sometimes even groups that move between companies as one, looking for new challenges (teams of professionals).

Space Tourism and Commercial Ventures

Commercial labs aren’t just about government contracts anymore. They’re also making space more accessible to regular folks and private businesses, not just astronauts with decades of training. Space tourism is slowly getting off the ground, with companies running short suborbital flights and longer missions being planned to the Moon and beyond.

Steps making this possible:

- Safety testing new vehicles for private passengers

- Developing training programs for non-professional astronauts

- Designing spacecraft for comfort as well as utility

Plus, aerospace labs are working with regulators on safety standards so anyone heading to the edge of space can do it with less risk and more confidence.

Space is no longer just for scientists and government agencies. With these changes, we’re starting to see everyday people looking out the window at Earth from above, and that’s a view you just can’t get anywhere else.

The Role of Aerospace Labs in Defense Innovation

Aerospace labs have changed how countries prepare for security challenges by coming up with cutting-edge solutions no one would have dreamed of twenty years ago. The pace of change is fast, and the work done in these labs is setting the tone for what the next wave of defense technology looks like. Let’s talk about where the action is happening:

Hypersonic Aircraft and Weapons Development

Just a few years ago, Mach 5 speeds seemed only possible in science fiction. Now aerospace labs are working with military contractors to design and test hypersonic missiles and unmanned vehicles that move so quickly, they can outpace traditional detection systems. Hypersonic weapons change how nations think about both offense and defense.

Key characteristics:

- Can travel over five times the speed of sound

- Unpredictable flight paths, making interception really tough

- Used for rapid global strikes or intelligence missions

Here’s how different countries are approaching hypersonics:

| Country | Funding (USD billions) | Major Projects |

|---|---|---|

| USA | 3.8 | ARRW, HAWC, LRHW |

| China | 2.6 | DF-ZF, Starry Sky-2 |

| Russia | 1.9 | Avangard, Zircon |

Stealth Technologies and Electronic Warfare

Stealth isn’t only about making jets invisible. Labs are coming up with ways to scramble sensors, jam signals, and fool enemy radar altogether. It’s like a game of digital cat and mouse.

Stealth and electronic warfare projects usually focus on:

- Special shapes and materials to deflect or absorb radar

- Systems for digital jamming and signal disruption

- Software that creates false images or hides movement

Modern fighters and drones wouldn’t last long without layered stealth and electronic defense systems developed on lab benches.

Autonomous Combat Drones

Combat drones that can patrol borders or enter hostile zones with no pilot onboard are already here. But the work in labs is now about making these drones:

- Smarter—planning their own routes and switching between objectives

- Safer—avoiding obstacles and threats on their own

- Connected—working in teams or sharing what they see back to human operators instantly

There’s a lot of competition in the industry right now with big names from both aerospace and tech, and a whole swarm of startups. Some drones even come equipped with onboard AI to identify and track targets without direct instructions from home base.

Defense innovation in aerospace isn’t slowing down anytime soon. With every breakthrough, the gap between today’s and tomorrow’s battlefield just gets wider. Labs remain the starting line for these leaps forward.

Digital Transformation and Automation in Aerospace Labs

These days, aerospace labs are moving past clipboards and spreadsheets. Digital transformation has become the backbone of how they operate. With machine learning, automation, and real-time data, labs are pushing boundaries that would’ve seemed impossible a decade ago. From production lines to airspace operations, almost everything has a digital touch. Let’s break it down by the key areas driving these changes.

AI-Powered Manufacturing and Robotics

Factories building airplanes and spacecraft are starting to look more like something out of a sci-fi film. Robots powered by artificial intelligence are tackling jobs that used to be slow, repetitive, or error-prone for humans. For example:

- Large aircraft manufacturers use AI-enabled machines to assemble complex parts, which improves accuracy and speeds up delivery.

- Sensors and cameras on production lines constantly feed data to AI systems, so adjustments happen on the fly.

- Robotics don’t take breaks or get tired, which means the night shift is just as efficient as the day one.

Collaboration is key too. Companies like RTX have found that by using powerful AI and combining aerospace data, they can create feedback loops. That keeps their AI-driven systems ahead of the pack.

Predictive Maintenance for Aircraft

It used to be that a plane would get checked every so often, whether it needed it or not. Now, predictive maintenance has turned that on its head. Each aircraft is packed with sensors, constantly feeding information about engine health, structural integrity, and more. AI crunches these numbers to spot trouble before it lands:

| Maintenance Strategy | Pros | Cons |

|---|---|---|

| Scheduled (time-based) | Simple to manage | Wasteful, lots of downtime |

| Reactive (fix after break) | Uses parts to limit | Can cause grounded planes, expensive |

| Predictive (AI-driven) | Early warnings, less waste | Needs data and tech investment |

Predictive maintenance brings

- Fewer surprise repairs

- Longer lifespan for expensive parts

- Safer flights, as problems are fixed before they become real issues

Data-Driven Flight Operations

Imagine planning a flight with only gut instinct. That’s basically what pilots and airlines did before data-driven systems took hold. Today, real-time analytics power decision-making in the air and on the ground. Flight operations use AI and big data for things like:

- Route optimization to avoid traffic and weather

- Fuel use monitoring in real time

- Fast rerouting and scheduling during disruptions

Aerospace companies are now sharing this type of data across suppliers, airlines, and labs. That way, everyone can act faster—sometimes even before problems crop up. This approach shows how digital transformation isn’t just about fancy gadgets, but about making the whole ecosystem smarter and more responsive.

Advanced Materials Research Transforming Aerospace Labs

Aerospace labs today look a lot more like high-tech workshops than the old concrete hangars you might picture. What’s driving all the recent buzz? It’s new materials—stuff you wouldn’t find on any plane from twenty years ago. These labs are pouring research time and resources into making materials that are lighter, tougher, and smarter. The right material can save millions on fuel, make flights safer, and even help spacecraft survive brutal conditions in space. Here’s where things are changing fast:

Ultra-Light Composites for Spacecraft

Planes and rockets used to be made from heavy metals, but now, composites—think carbon fiber or even newer blends—are everywhere. Why? They give you strength without the weight penalty. Saving weight in a plane or rocket generally means:

- Using less fuel for the same trip

- Hauling more cargo or equipment

- Achieving longer range

Let’s keep it simple. Here’s how composite materials stack up against classic metals:

| Material | Strength-to-Weight | Corrosion Resistance | Common Use Case |

|---|---|---|---|

| Aluminum Alloy | Medium | Medium | Fuselages, wings |

| Carbon Fiber | High | High | Spacecraft, drones |

| Titanium Alloy | High | High | Engine parts, landing gear |

Aerospace labs keep tweaking these blends for even better results. Tomorrow’s planes might weigh half as much and last twice as long.

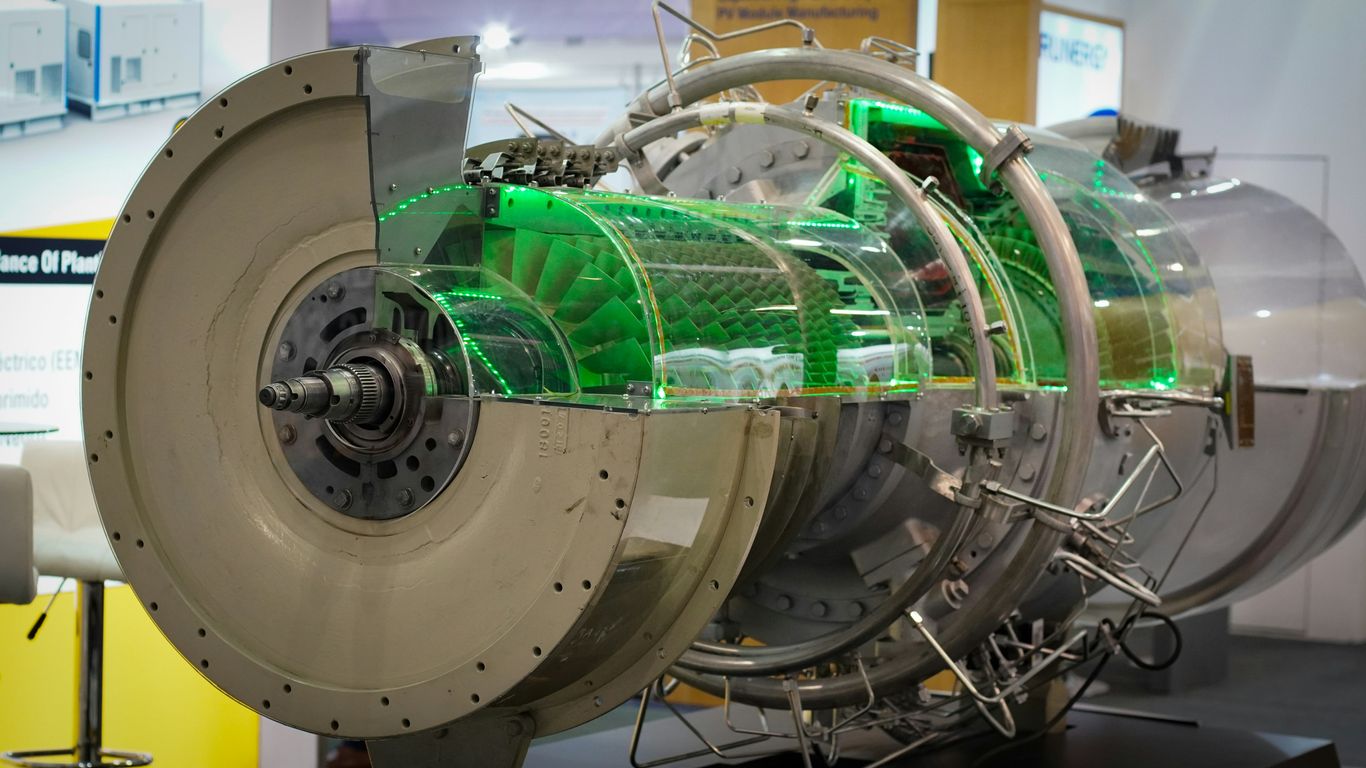

Heat-Resistant Alloys and Their Applications

Space travel means a ton of heat and cold swings. On takeoff, re-entry, or even orbit, regular metals can’t always cut it. So, labs are inventing new alloys—superalloys, really—so that engine parts and skin panels can handle:

- Repeated, drastic temperature changes

- Exposure to plasma and intense sun

- High pressures without melting or breaking

What’s interesting is the combination of metals: engineers blend nickel, cobalt, even rare elements to get the right mix. Imagine launching a rocket, knowing its engines can tolerate thousands of degrees over and over without turning brittle or falling apart. That’s the power of modern alloys.

Smart Materials for Adaptive Structures

This sounds futuristic, but it’s already real. Smart materials can change shape or stiffness, which helps with aerodynamic control or rapid repairs. Some can even sense damage and "heal" themselves, kind of like biological tissue healing a scratch. In aerospace labs, these materials are used to create wings that change shape in flight, or spacecraft skins that patch up minor cracks automatically.

Honestly, there are still challenges with costs and scaling up production, but researchers are working on that. Here’s what smart materials are starting to do:

- Change form automatically to reduce turbulence

- Absorb and disperse heat more evenly

- Alert ground control to structural weaknesses before they become a problem

If all this sounds a bit sci-fi, that’s because it is—but it’s happening right now in aerospace research centers. The next generation of planes and rockets will be defined more by what they’re made of than ever before.

Collaborative Partnerships Shaping Aerospace Labs Innovations

Aerospace labs today don’t work in a vacuum—they rely on strong partnerships to get things done, and those partnerships are changing the whole industry.

Cross-Sector Research Initiatives

Let’s be honest: aerospace projects are way too big for any single player to handle alone. It’s pretty common to see universities working with manufacturers and research centers, pooling their brainpower and resources to tackle tough problems. For instance, aerospace innovation centers bringing together universities and industry leaders are showing how much can be achieved when everyone works together.

Some things that make these initiatives work include:

- Sharing expensive lab equipment and simulation software

- Combining different areas of expertise—think engineers, software developers, and material scientists all in one room

- Jointly publishing research, which helps the whole field move forward

When all these worlds collide, new ideas move from sketches on napkins to actual working technology much faster.

Government Funding and Grants

Government support keeps the momentum going, especially when it comes to early-stage innovation. Agencies at both the national and local level pour money into promising aerospace ideas that might not attract private investors right away. That means more people can test out risky concepts, and the biggest breakthroughs often start with public funds.

Here’s a quick comparison of who’s giving what in the last five years:

| Country | Total Grant Funding (USD, Billions) | Focus Areas |

|---|---|---|

| United States | 7.8 | Space propulsion, avionics, AI in flight |

| Canada | 2.1 | Materials, sustainability, urban mobility |

| European Union | 5.4 | Satellite tech, reusable rockets |

Grant cycles move fast, and labs that stay plugged in are the ones that keep testing, building, and pushing ahead.

Public-Private Partnerships in Space Missions

When you see a new satellite launch or a commercial rocket test, there’s a good chance it came out of a public-private mix. These partnerships bring the best of both worlds: government stability and regulatory know-how paired with the speed and fresh thinking of private firms.

Some successful examples:

- NASA’s collaboration with SpaceX and Boeing for crewed missions

- Joint ventures between smaller startups and government research agencies for orbital transfer vehicles

- Local aerospace innovation hubs that blend municipal support with industry commitments

Public-private partnerships are reshaping how space missions are planned, funded, and even who can participate. The bottom line is that with everyone at the table, more ideas get out the door and into the sky.

Conclusion

So, after looking at all the wild stuff happening in aerospace labs, it’s pretty clear we’re living in a time where science fiction is starting to feel like regular news. These labs aren’t just building faster planes or cooler rockets—they’re changing how we think about travel, safety, and even life on other planets. Sure, there are still some big hurdles, like figuring out the rules for new tech or making things affordable, but the progress is hard to ignore. Every year, new ideas come out of these labs that make yesterday’s breakthroughs look old. Whether it’s electric planes, reusable rockets, or tiny satellites, the pace is only picking up. If you ask me, the future of aerospace isn’t just about flying higher or farther—it’s about making the impossible seem normal. And honestly, that’s pretty exciting.

Frequently Asked Questions

How are aerospace labs making airplanes more eco-friendly?

Aerospace labs are working on new ways to make airplanes better for the environment. This includes using electric engines, special fuels made from plants or waste, and building planes out of lighter materials. These changes help airplanes use less fuel and create less pollution.

What is the importance of reusable rockets in space travel?

Reusable rockets can be used more than once, which makes space trips much cheaper and less wasteful. Instead of throwing away rockets after one use, companies like SpaceX land them safely so they can fly again. This helps us explore space more often and saves money.

How do aerospace labs help keep countries safe?

Aerospace labs create new technology for defense, like super-fast planes, stealthy jets that are hard to spot, and smart drones that can fly by themselves. These inventions help protect countries and make them ready for new kinds of threats.

What role does artificial intelligence play in aerospace labs?

Artificial intelligence, or AI, is used in aerospace labs to make building and fixing airplanes easier and faster. AI can help robots build parts, predict when something might break, and help pilots make better decisions during flights.

Why are new materials important for airplanes and spaceships?

New materials, like super-light composites and metals that can handle extreme heat, help airplanes and spaceships go faster, use less fuel, and stay safe in tough conditions. These materials are strong but don’t weigh much, which is very important for flying.

How do partnerships help aerospace labs create new ideas?

Aerospace labs often work together with schools, companies, and governments. By sharing knowledge and money, they can solve big problems faster and invent things no one could do alone. These partnerships are key to making big leaps in technology.