Key Innovations Driving Robotics 2024

The robotics landscape in 2024 is changing faster than ever before. Tech is shifting focus from just building robots to creating smart, adaptable systems that really work alongside humans. This year, three standout trends are leading the way: smarter automation with AI, sensors that make robots more aware, and easier ways for humans and robots to connect and work together.

AI and Machine Learning for Adaptive Automation

Robotics in 2024 relies heavily on artificial intelligence and machine learning, making systems more flexible and able to handle unpredictable real-world environments. Here’s how it shows up:

- Robots no longer just repeat one task; they can recognize changes on the fly, like when parts move slightly or lighting shifts.

- ML tools let robots analyze sensor data in real time, shifting their behavior to avoid mistakes and keep processes running smooth.

- Predictive systems track performance — so, if a robot part’s about to fail, the system picks it up early, minimizing costly downtime.

Below is a simple table showing some common adaptive AI applications in modern robots:

| Application | Example in Robotics |

|---|---|

| Object Recognition | Identifying odd-shaped objects |

| Dynamic Path Planning | Avoiding sudden obstacles |

| Predictive Maintenance | Warning before motor failures occur |

For industries that rely on uptime and flexibility, this kind of automation is changing the game.

Next-Generation Sensing and Perception Systems

Sensors today do more than just detect objects; they let robots really “see” and “feel” their world with meaningful accuracy.

- Robots mix info from cameras, depth sensors, and even microphones for a 360-degree view. This is big in places like hospitals and building sites, where things change quickly.

- Touch-sensitive surfaces and force sensors help robots grip fragile things (like glassware) or do delicate assembly.

- AI combines all this data, so a robot doesn’t just spot a person— it can tell if they’re walking, carrying something, or standing still, making safety routines smoother.

These advanced perception systems are a core piece of how driverless and shared vehicles are taking off (more about the shift in transportation).

Human-Robot Collaboration Technologies

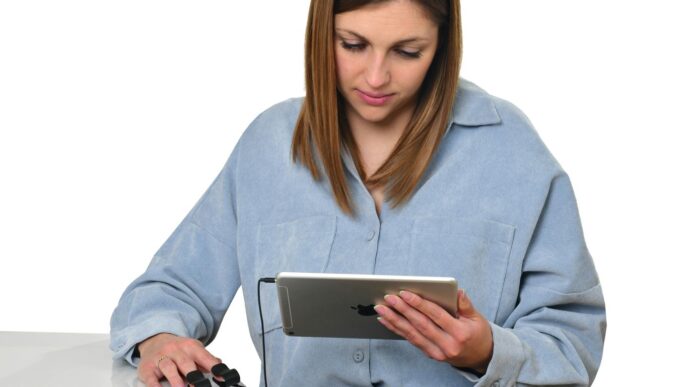

Working with machines is becoming less about pushing buttons and more about natural teamwork, thanks to smarter interactions.

- Today’s cobots use safer, more robust hardware that allows for human contact and joint tasks.

- Voice control is becoming the norm — simple commands like “lift that box” actually work.

- Robots can now notice gestures or expressions, letting people interact with them in ways that feel intuitive.

- Some workplaces use AR (augmented reality) overlays to guide both robots and humans, cutting down on confusion and speeding up setup.

To sum it up, the robotics field isn’t just advancing in power, it’s becoming more adaptable and more accessible. The line between people and machines is starting to blur, and in most cases, that means better results for everyone.

Expanding Industrial Applications of Robotics 2024

Robots aren’t just stuck in car factories or on the assembly line anymore. Now, they’re popping up all over the place, doing jobs faster, safer, and sometimes even smarter than before. In 2024, some of the biggest changes are happening in the way robots are used in industry, all thanks to tech advances, smart sensors, and companies wanting to work more efficiently. Let’s break down some of the biggest shifts.

Smart Manufacturing and Autonomous Assembly Lines

Smart factories are moving far beyond traditional automation, with humanoid robots, mobile arms, and AI working side-by-side with people.

- Modern manufacturing is run by networks of robots and machines that talk to each other, adjusting instantly if something changes on the line.

- Dark factories (places that don’t need the lights on for humans) are becoming more common. In these spaces, robots work 24/7, rarely stopping.

- Sensors track every little movement, data gets shared instantly, and predictive models nip problems in the bud before things break down.

| Process | Manual Labor (Hours/Week) | With Robotics (Hours/Week) | Defect Rate (%) |

|---|---|---|---|

| Traditional Assembly | 200 | 40 | 4.5 |

| Autonomous Assembly | 60 | 10 | 1.2 |

Advanced Robotics in Construction and Demolition

The construction world is making robots part of the crew. It’s not all futuristic either—it’s happening now.

- Automated bricklaying and 3D-printing robots are starting to build walls, facades, and even entire homes, doing it faster than traditional crews.

- Robots with sensors and cameras do dangerous demolition work, keeping people out of harm’s way. They can also handle precise excavation for tight urban spaces.

- Drones and climbing bots do inspections on tall structures, helping spot cracks, corrosion, or other problems that a human would miss.

Key benefits include:

- Lower risk of injury for workers.

- Consistent results—fewer surprises.

- Faster project timelines, so projects finish on schedule.

Predictive Maintenance and Quality Control Automation

Predictive maintenance used to sound like a buzzword, but now it’s just how things are done. Sensors on equipment send real-time updates about wear and tear, letting maintenance teams fix things before they break.

- Vision systems and robotic arms check everything from welds to cosmetic flaws, spotting problems that slip past even the sharpest eyes.

- AI crunches the numbers, looking for patterns that signal a breakdown or quality slip is around the corner.

- When something’s off, robots or technicians get an alert, and action is taken before it causes a loss.

Big advantages of this approach:

- Machines last longer—fewer costly breakdowns.

- Less waste because fewer parts fail mid-production.

- People spend less time firefighting, and more time making improvements.

The bottom line is, industrial robots in 2024 are changing what factories, construction sites, and plants look like. The jobs are safer, production is smoother, and companies can keep their promises to customers. Robots aren’t just replacing people; they’re making new kinds of work possible, too.

Robotics 2024 in Healthcare and Service Industries

The conversation about robots in 2024 isn’t just happening in labs—it’s all over hospitals and customer-facing businesses, too. The new batch of robots is starting to really change how people get medical care, keep their homes running, and even shop or stay in hotels. Let’s look at what’s happening, and how it feels up close.

Robotic-Assisted Surgeries and Patient Care

The buzz about robotic surgery began years ago, but now some hospitals won’t operate any other way. These systems can do things like stitching tiny blood vessels, cutting away tumors without making huge incisions, and even helping doctors spot complications early by using advanced imaging and data analysis. Surgeons are saying robot arms help their hands be steadier, especially for delicate moves.

Here’s a quick look at how robots are getting into patient care:

- Operating rooms with robots that enhance imaging and accuracy.

- Portable robots assisting nurses by moving heavy hospital beds and equipment.

- Smart exoskeletons that help patients learn to walk again after an injury.

| Usage Area | Outcome | Notable Facts |

|---|---|---|

| Surgery | Faster recovery, fewer errors | 25% more precision reported |

| Rehabilitation | Improved mobility | Used in 200+ clinics |

| Diagnostics | Early detection of diseases | AI-driven data analysis |

Personalized Domestic Robots for Everyday Tasks

It’s not like the sci-fi movies (yet), but home robots are taking on basic jobs. Think of them as helpful, reliable machines for simple but annoying chores. People are finding real benefits, especially the elderly or anyone who needs a little extra help:

- Vacuuming, mopping, or even prepping simple meals with minimal human oversight.

- Reminders for medications and daily routines.

- Keeping an eye on safety—like alerting someone if a fall happens.

Some folks are even giving nicknames to their robots—like calling the vacuum “Dusty”—because these things are around enough to feel like part of the family.

Robotics in Retail and Hospitality Services

Stores and hotels are getting a lot more hands-off, but not in a cold way. Robots are greeting customers, checking inventory, and handling simple tasks round the clock. If you’ve ordered fast food and a robot delivered it, you’ve probably already seen this in action.

Key ways robots are showing up here:

- Shelf-checking droids in grocery stores spotting empty spots.

- Small delivery robots bringing room service or shopping orders to guests.

- Info kiosks that answer standard questions from shoppers or travelers in multiple languages.

Robotics are making everyday services quicker and more consistent, though there’s still plenty of work for humans behind the scenes. It’s a bit odd the first time, but after a while, you start to expect it—like self-checkout lanes a decade ago. The big trick in 2024 is keeping all this tech reliable, easy to use, and genuinely helpful rather than just showing off.

Addressing the Skills Gap in Robotics 2024

Finding people with the right skills for modern robotics is a real problem in 2024. As robots show up everywhere—on factory floors, in hospitals, even in daily life—the demand for folks who know how to build, run, and fix them keeps growing. The widening gap between robotics careers and available talent isn’t just an industry headache; it shapes how fast we all adapt to these technologies.

Upskilling and Workforce Retraining Initiatives

Companies are pouring resources into reskilling workers who might otherwise get left behind. Some major approaches include:

- Free or subsidized robotics bootcamps for employees

- On-the-job mentorships pairing newcomers with robotics engineers

- Online micro-credential courses in programming, hardware maintenance, and AI fundamentals

Here’s a quick look at retraining efforts by sector:

| Sector | % Companies Investing in Retraining |

|---|---|

| Manufacturing | 68% |

| Healthcare | 54% |

| Logistics | 41% |

| Retail | 33% |

As emerging technologies like gesture-controlled machines and AI-powered vehicles reshape routine tasks, upskilling isn’t optional—it’s survival.

Integrating Robotics Education in STEM Programs

Schools and universities are revising STEM curriculums so robotics isn’t just a side project. You’ll see:

- Hands-on robotics labs added as required courses

- Classes focused on computer vision, sensors, and ethical questions

- Opportunities for students to team up on community robotics competitions or industry-sponsored hackathons

The trick is making sure the learning stays practical, not just theory. Many students now build robots for real-world challenges, not just simulations.

Promoting Diversity and Inclusion in Robotics Careers

Bridging the skills gap also means opening doors to more kinds of people. Some ways the field is making progress:

- Partnering with minority-serving colleges and groups to run free robotics workshops

- Career days and mentorship programs led by underrepresented engineers

- Encouraging more women to join robotics by highlighting leaders and creating inclusive hiring practices

There’s growing evidence that greater workforce diversity brings new ideas to robotics and helps close the gender gap in the industry. The push for inclusion goes beyond just numbers—it’s about encouraging everyone to see themselves as part of the future of robotics.

Ethical and Societal Considerations in Robotics 2024

The spread of robotics in daily life and industry isn’t just about new gadgets. It’s also about new questions for people, companies, and governments. Robots are popping up everywhere, so it’s time to talk honestly about safety, bias, and trust in this tech.

Ensuring Safety in Human-Robot Interactions

People want to feel safe around robots, whether at work or in public. Robots are moving from cages on factory floors into homes, hospitals, and busy workplaces. But it’s not as simple as putting in an emergency stop button or a warning sign. Programs have to be checked and updated. People need clear rules for how to act when a robot is nearby. There are a few basics everyone’s trying to sort out:

- Setting clear boundaries for where robots should and shouldn’t go.

- Training users and operators—not just on buttons, but on what to expect from a robot’s movement or decisions.

- Making sure all robots, from small delivery bots to surgical arms, meet new safety standards before they ever get near the public.

| Year | Robot/Human Injury Incidents (Reported)* |

|---|---|

| 2021 | 128 |

| 2022 | 139 |

| 2023 | 132 |

| 2024 (projected) | 127 |

*Data: International Robotics Safety Association.

Tackling Bias and Fairness in Intelligent Systems

As robots get smarter, problems with bias show up in new places—like hiring bots refusing certain applicants or delivery robots avoiding certain neighborhoods. How do we know the AI making choices inside these machines is fair?

- Testing robots with all kinds of real data, not just perfect lab datasets.

- Regular, public audits of robot decision systems.

- Involving more people—from different walks of life—in designing and checking robotic systems.

A lot of these systems learn from data that might be old or unfair by accident. Until there are better ways to check for these patterns, bias won’t go away on its own.

Building Public Trust and Transparency

If robots are going to work side-by-side with people, trust is a must. That’s not just about safety—it’s about explaining how robots work, what data they use, and what choices they’re allowed to make. The problem? Most people don’t want a technical manual, they want plain-English answers. Here are a few things that help:

- Simple explanations (not buried in fine print) for users and the public about what a robot knows, sees, and does.

- Clear contact points or hotlines if someone wants answers about a robot’s actions.

- Open announcements when a robot’s job or programming changes.

Public trust will be won—and lost—one small decision at a time. If companies or governments hide problems, suspicions will grow. It’s a slow process, but clear rules and honest conversations matter more than technical wizardry in the long run.

Overcoming Technical Challenges in Robotics 2024

The robotics world faces some big hurdles that go beyond flashy demos and prototypes. This year, technical challenges like getting different robots to cooperate, keeping them safe from hackers, and powering them for long stretches without a recharge are all front and center.

Interoperability and Industry Standards

Trying to get robots and all their parts to work together is, honestly, a huge headache. Every company seems to use its own software, connectors, and controls, so putting two different bots on the same assembly line is a recipe for frustration.

Industry standards are the glue that holds the future of robotics together. Here’s what companies (and engineers) are running into:

- Integration nightmares: It’s easy for even simple robots to talk past each other if their systems aren’t compatible.

- Custom fixes everywhere: No global standard means every new connection is a patch job.

- Slowed progress: Developers and manufacturers spend more time troubleshooting than building new features.

A few groups are working on unified robotic frameworks, but broad adoption has been slow. Labs and startups need clear standards to collaborate, scale, and compete globally.

Cybersecurity for Connected Robotic Systems

Let’s get real—robots aren’t just cool machines; they’re computers on wheels (or tracks, or arms). The minute you connect them to a factory network or Wi-Fi, doors open for possible attacks. Security holes can lead to:

- Unauthorized control: Hackers could take over robotic systems.

- Data leaks: Sensitive info from sensors or cameras could fall into the wrong hands.

- System shutdowns: Cyberattacks can slow production or, worse, cause safety risks for people nearby.

Companies are starting to:

- Encrypt all data sent between robots and control systems

- Regularly update firmware and software

- Segment networks, so one breach doesn’t bring everything down

But the ongoing cat-and-mouse game between cybersecurity experts and hackers is far from over.

Energy-Efficient Hardware and Autonomous Power

Running robots on batteries is no joke. In warehouses or on job sites, power draws are always a limiting factor. There’s just no fun in watching a robot stop mid-task to charge.

Key approaches to power problems:

- Lightweight batteries: Every ounce counts, so performance per weight is king.

- Smarter power management: Robots that adjust movement and processing to save juice.

- Harvesting energy: Some systems try to draw power from light or heat in their surroundings, but it’s early days.

Here’s a side-by-side look at some battery types commonly used in 2024 robotics:

| Battery Type | Energy Density (Wh/kg) | Typical Runtime (hrs) | Recharging Speed |

|---|---|---|---|

| Li-ion | 150–200 | 6–12 | Fast |

| Li-Po | 180–220 | 8–14 | Moderate |

| Solid-State | 250+ | 10–18 | Slow |

Getting longer runtimes without bulkier batteries is the ongoing challenge. Small gains in energy density mean hours of extra work in the field or factory.

Bottom Line

Technical hurdles aren’t stopping robotics, but they do slow things down. Standards get everyone speaking the same language, cybersecurity is the gatekeeper, and smart power keeps robots rolling. Cracking these problems will make robots cheaper, safer, and way more useful for everyone—not just the biggest companies on the block.

Making Robotics 2024 Accessible and Scalable

Robotics used to be something only big companies could afford, but 2024 is changing the rules. New developments are bringing costs down and making robots easier to use, even for small businesses or people who aren’t engineers. Let’s talk about three key things making this possible: modular design, no-code tools, and cloud-based services.

Lowering Costs with Modular Designs

Robots aren’t just expensive one-size-fits-all machines anymore. Today, makers are building them in pieces—so businesses can start with the basics and add features later. This helps:

- Avoid big upfront spending

- Make repairs and upgrades less of a headache

- Support a mix-and-match approach—need a gripper or a vision sensor? Just add it

| Feature | Traditional Robots | Modular Robots |

|---|---|---|

| Upfront Cost | High | Lower |

| Upgrades | Complex/Expensive | Simple/Add-on |

| Customization | Limited | Flexible |

Simplified Programming and No-Code Tools

A huge barrier used to be programming—writing lines and lines of code isn’t easy. Thankfully, that’s not a must anymore. There’s a push toward easy-to-use tools:

- Drag-and-drop visual interfaces

- “Teach by demonstration” (physically show a robot a task)

- Apps and dashboards with ready-made functions

This means someone who knows the job—but not how to code—can teach a robot what to do. It opens doors for schools, workshops, and local businesses everywhere.

Cloud Robotics and Robot-as-a-Service Models

Think Netflix, but for robots. Companies now offer robots or automation as a subscription. No mega investment needed, just pay as you go. Plus, connecting robots to the cloud lets you:

- Use powerful software hosted online, cutting hardware costs

- Update and manage fleets of robots from anywhere

- Share data and insights for smarter operation

| Benefit | Impact |

|---|---|

| Lower entry cost | More people can try robots |

| Easier management | Fewer headaches, quicker fixes |

| Flexibility | Scale up or down anytime |

Robotics 2024 isn’t just about more powerful machines—it’s about making them something everyone can access, use, and actually afford. It’s not perfect yet, but we’re seeing the first signs that robots might just be for everyone soon.

Conclusion

So, where does all this leave us? Robotics in 2024 is moving fast, and it’s not just about fancy machines in labs or factories anymore. We’re seeing robots pop up in hospitals, warehouses, and even in our homes. Sure, there are some big questions to answer—like how we keep jobs for people, make sure robots are safe, and protect against hacking. But there’s also a lot to be excited about. Robots are helping us do things that are tough, boring, or even dangerous. They’re making some jobs easier and opening up new ones that didn’t exist before. As long as we keep learning, stay open to change, and work together, the future of robotics looks pretty bright. It’s not about robots taking over—it’s about people and machines teaming up to do more than either could alone. The next few years should be interesting, to say the least.