Ever wondered how quantum chips go from a plain silicon wafer to a working device? In this article, I’ll take you inside rigetti quantum computing fab 1, the first plant built just for making quantum chips. You’ll see why it was set up, what happens in the dust-free cleanroom, how each layer is added and etched, why the chips are made in Lego-style blocks, and how they link up with the gear that talks to the cloud. Let’s get started.

Key Takeaways

- Why rigetti quantum computing fab 1 was built and what it aims to achieve

- A look at the cleanroom rules and how they keep things dust-free

- How layers get added and etched away to form qubit structures

- What makes the modular layout feel like Lego blocks

- How the finished chips connect to control boards and the cloud

The Vision Behind Rigetti Quantum Computing Fab One

Origins Of Full-Stack Quantum Computing

Okay, so Rigetti wasn’t messing around when they got into quantum computing. They didn’t just want to make a single component; they wanted the whole stack. That’s why they aimed to control everything from the quantum chips themselves to the cloud software that lets you use them. It’s like building a computer from scratch, but, you know, with quantum mechanics involved. This approach lets them really optimize each part to work well with the others. It’s a bold move, but it seems to be paying off.

Commissioning Of The Dedicated Fabrication Facility

Fab-1 is a big deal. It’s not just some lab; it’s a dedicated facility specifically for making quantum chips. Rigetti realized early on that if they wanted to push the boundaries, they needed their own place to experiment and refine their manufacturing processes. Think of it like this: if you want to make the best pizza, you don’t just buy dough from the store; you make your own from scratch. Fab-1 is their from-scratch dough factory. This gives them way more control over the quality and precision of their chips. It’s a pretty big investment, but it shows they’re serious about being a leader in the quantum game. The quantum computing education is important.

Foundational Role In Superconducting Qubit Development

Superconducting qubits are kind of Rigetti’s thing. Fab-1 plays a huge role in making these qubits better and better. It’s where they test new materials, try out different designs, and generally push the limits of what’s possible. It’s not just about making more qubits; it’s about making better qubits – ones that are more stable, more accurate, and more powerful. Fab-1 is the engine that drives this innovation. It’s where the magic happens, where they turn ideas into actual, working quantum components.

Milestones In Early Modular Chip Design

Rigetti’s been working on modular chip designs for a while now. The idea is to create quantum chips that can be easily scaled up by connecting smaller blocks together, kind of like Lego bricks. Fab-1 has been instrumental in achieving key milestones in this area. They’ve gone from basic prototypes to more complex designs, constantly improving the way these modules connect and interact. This modular approach is key to building larger, more powerful quantum computers in the future. It’s all about making quantum computing scalable and practical. The company designs and manufactures its chips in-house at Fab-1, the industry’s first dedicated quantum device manufacturing facility.

State-Of-The-Art Cleanroom Workflows

Okay, so picture this: building quantum chips isn’t like assembling your average computer. We’re talking about stuff on an atomic scale, which means the environment has to be pristine. That’s where the cleanroom comes in. It’s not just about keeping things tidy; it’s about controlling every single variable to ensure the chips come out perfect. It’s a bit like a hospital operating room, but for quantum circuits.

Controlled Environment Protocols

First off, getting into the cleanroom is an event. Think full-body suits, masks, and special shoes – the whole nine yards. It’s not just for show; even a tiny speck of dust can mess up the whole process. The air is constantly filtered to remove particles, and the temperature and humidity are tightly controlled. We’re talking about Class 100 or even Class 10 cleanrooms in some areas, meaning there are fewer than 100 particles (or 10!) of 0.5 microns or larger per cubic foot of air. It’s cleaner than an operating room! Here’s a quick rundown:

- Strict gowning procedures: Full-body suits, masks, gloves, and booties.

- Air filtration: HEPA and ULPA filters to remove particles.

- Environmental monitoring: Continuous tracking of temperature, humidity, and particle counts.

Advanced Photolithography Techniques

Photolithography is how we pattern the circuits onto the silicon wafers. It’s like using a stencil to etch the design, but with light. We use incredibly precise lasers and lenses to project the circuit design onto the wafer, which is coated with a light-sensitive material. The exposed areas become the circuit. It’s a delicate process, and any vibration or imperfection can ruin the whole thing. Rigetti is working with an Air Force Office of Scientific Research award to improve chip fabrication technology.

In-House Cryogenic Testing Stations

Once the chips are made, they need to be tested at extremely low temperatures – close to absolute zero. That’s where the cryogenic testing stations come in. These are basically super-cooled refrigerators that allow us to simulate the operating environment of the quantum computer. We can then measure the performance of the qubits and identify any issues. Doing this in-house is a huge advantage because it allows us to quickly iterate on the design and fabrication process. It’s all about speed and precision. We can run new chip design starts multiple times a week.

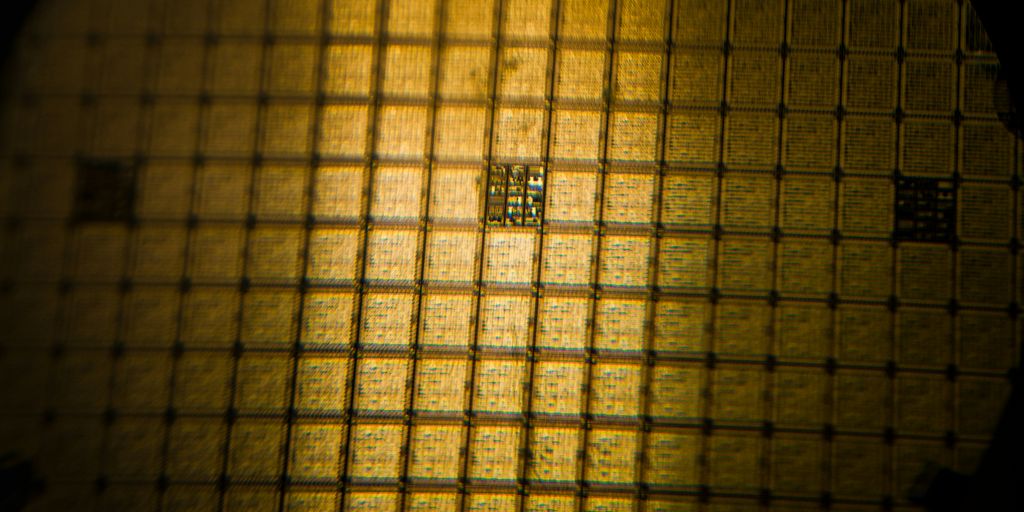

From Silicon Wafer To Quantum Chip

Layer Deposition And Etching Precision

Turning a simple silicon wafer into a complex quantum chip is quite the process. It all starts with incredibly precise layer deposition. We’re talking atomic-level control here. Think of it like building with Legos, but instead of plastic bricks, you’re using materials that are only a few atoms thick. Each layer has to be perfect, or the whole thing falls apart. Then comes etching, where we remove material to create the patterns that define the qubits and their connections. The precision needed for advanced chip design is mind-boggling; even tiny imperfections can throw off the quantum behavior.

Superconducting Material Integration

Next up is integrating superconducting materials. This is where things get really interesting. We need materials that lose all resistance to electricity at extremely low temperatures. Typically, we’re talking about aluminum or niobium. Getting these materials to play nice with the silicon and other layers is a challenge. The interfaces between the materials have to be perfect to maintain superconductivity. It’s a delicate balance, and getting the superconducting properties just right is critical for qubit performance.

Multi-Chip Assembly Strategies

As quantum computers get bigger, we can’t just cram everything onto a single chip. That’s where multi-chip assembly comes in. We fabricate smaller chiplets and then carefully assemble them into a larger quantum processor. This is like building a house from prefabricated modules. The challenge is connecting these chiplets together without introducing noise or losing coherence. It requires very precise alignment and bonding techniques. Think of it as high-tech quantum Lego building.

Tunable Coupler Fabrication

Tunable couplers are what allow us to control the interactions between qubits. They’re like tiny switches that turn on or off the connection between two qubits. Fabricating these couplers is a real art. We need to be able to precisely control their properties so that we can tune the strength of the interaction between qubits. This involves carefully designing the geometry of the coupler and choosing the right materials. The ability to fabricate high-quality tunable coupler innovations is key to building powerful quantum computers.

Rigetti’s Proprietary Modular Architecture

Okay, so Rigetti’s approach to building quantum computers is pretty interesting. They’re not just trying to cram more qubits onto a single chip; they’re thinking bigger, like building with Lego blocks. It’s all about making things scalable and manageable.

Square Lattice Qubit Layouts

Rigetti uses a square lattice layout for their qubits. Basically, instead of arranging qubits in a line or some other random way, they put them in a grid. This makes it easier to connect them and control them. It’s like organizing your desk so you can actually find stuff. The Ankaa system uses this architecture.

Scalability Through Lego-Style Chip Blocks

The idea here is that you can build bigger and bigger quantum processors by connecting these chip ‘blocks’ together. Think of it like building a computer out of individual components, but on a quantum level. Chad Rigetti even referred to them as "Lego blocks". This modular approach is key to scaling up the number of qubits without making the whole system too complex to handle. It’s a multi-chip solution quantum processor for scalable quantum computing systems.

Tunable Coupler Innovations

Tunable couplers are like the switches that control how qubits interact with each other. Rigetti has been working on making these couplers better, so they can precisely control the interactions between qubits. This is super important for performing quantum computations accurately. It’s like having a really precise volume knob on your stereo – you can fine-tune the sound just right. The Ankaa system uses tunable couplers.

Gate Speed Optimization Techniques

Gate speed is how fast you can perform operations on the qubits. The faster the gate speed, the faster you can run quantum algorithms. Rigetti is constantly working on ways to speed up these gates, which involves tweaking the materials, the chip design, and the control electronics. The latest generation Ankaa system features 2x faster gate speeds.

Integrating Quantum Chips With Classical Infrastructure

It’s not enough to just make a quantum chip. You’ve got to figure out how to make it play nice with the regular computers we already use. That’s where integrating quantum chips with classical infrastructure comes in. It’s all about building the bridges that let these two very different worlds talk to each other. This integration is key to unlocking the real potential of quantum computing.

High-Performance Cryogenic Control Electronics

Quantum chips need to be kept super cold – we’re talking temperatures colder than outer space. To achieve this, we use cryogenic systems. But keeping them cold is only half the battle. You also need electronics that can operate at those temperatures to control the qubits. These aren’t your average circuits; they need to be specially designed to work in extreme cold without adding too much heat. It’s a tricky balancing act, but essential for precise qubit control. Think of it like trying to play a delicate piano piece while wearing mittens – you need specialized tools for the job.

Cloud Connectivity And Data Routing

Okay, so you’ve got your quantum chip humming along in its super-cooled environment. Now, how do you actually use it? That’s where cloud connectivity comes in. We need to be able to send instructions to the chip and get the results back out, all through the cloud. This means building robust data routing systems that can handle the unique demands of quantum data. It’s not just about bandwidth; it’s about making sure the data arrives intact and on time. Rigetti launched the first hybrid cloud platform in 2018, and it’s been a priority ever since to make QPUs accessible to the quantum computing ecosystem.

Automated Calibration And Error Correction

Qubits are notoriously finicky. They’re easily disturbed by noise, which can lead to errors in calculations. That’s why automated calibration and error correction are so important. We need systems that can constantly monitor the qubits, detect errors, and correct them in real-time. This is a complex task that requires sophisticated algorithms and a lot of computing power. It’s like having a spellchecker for quantum computations, constantly working in the background to make sure everything is accurate. The goal is to solve problems that would be taxing if not impossible for classical computers.

Quality Assurance And Performance Validation

Quality assurance is super important in quantum computing. You can’t just build these things and hope they work. You need to test, test, and test again. We’re talking about incredibly sensitive systems, so even the smallest error can throw everything off.

Cryogenic Acceptance Testing

Before a quantum chip even makes it out of the fab, it goes through rigorous testing at cryogenic temperatures. This is because superconducting qubits only exhibit quantum behavior at extremely low temperatures, typically just a few millikelvins above absolute zero. We need to make sure everything is working as expected in the actual operating environment. This involves:

- Checking for shorts or open circuits.

- Verifying the resonant frequencies of the qubits.

- Measuring the coherence times of the qubits.

Fidelity Measurement Protocols

Once the chip passes the initial acceptance testing, we move on to more detailed performance characterization. This is where we really put the qubits through their paces. We use a variety of techniques to measure the fidelity of quantum gates, which is a measure of how accurately the qubits perform the desired operations. Some of the key metrics we track include:

- Single-qubit gate fidelity: How accurately can we rotate a single qubit?

- Two-qubit gate fidelity: How accurately can we entangle two qubits?

- Readout fidelity: How accurately can we measure the state of a qubit?

| Metric | Target Value | Achieved Value |

|---|---|---|

| Single-Qubit Fidelity | >99.9% | 99.92% |

| Two-Qubit Fidelity | >99.5% | 99.65% |

| Readout Fidelity | >99.0% | 99.20% |

These measurements help us identify any problems with the chip and optimize its performance. Novera QPU calibration is a key step in this process.

Automated Fault Detection

As quantum computers get bigger and more complex, it becomes impossible to manually monitor every single qubit. That’s why we’re developing automated fault detection systems that can quickly identify and diagnose problems. These systems use machine learning algorithms to analyze data from the qubits and detect anomalies that might indicate a fault. This allows us to quickly address any issues and minimize downtime. It’s like having a team of quantum mechanics constantly monitoring the system, but without the need for sleep or coffee breaks. This is especially important as we scale up to larger qubit counts, where manual calibration becomes a bottleneck. AI-powered calibration tools are becoming essential for maintaining the exacting standards required for quantum computation.

## Conclusion

In this tour of Rigetti’s Fab-1, you saw how a chip goes from drawing to real hardware. You saw the clean rooms, the circuits and the test stands. It’s part workshop and part science fair. They design a chip, make it, test it on their cloud control system, then do it again until it works better. It’s not all smooth. Some runs fail, some parts break. But having their own factory means they can change things on the fly. That’s how they move from the first Agave device to today’s fast Ankaa system—and beyond.

Frequently Asked Questions

What is Rigetti’s Fab-1 factory?

Fab-1 is Rigetti’s own chip factory. It opened in 2016 and was the first place built just for making quantum chips.

Why does Rigetti use a cleanroom?

A cleanroom keeps dust and dirt away from the chips. This helps the tiny parts stay perfect and work the right way.

How do they turn a silicon wafer into a quantum chip?

They start with a smooth silicon disc. Then they add and remove thin layers with special tools until the chip has the right shapes and parts.

What makes Rigetti’s chip design special?

Rigetti uses a modular design like Lego blocks. This lets them snap small chip pieces together so they can build bigger systems easily.

How do quantum chips connect to regular computers?

They use fast, cold electronics that send signals back and forth at super-low temperatures. Then the data moves over the cloud to normal servers.

How does Rigetti check chip quality and speed?

They cool each chip down and run tests to see if the qubits work well. They also measure how fast the chips can do basic quantum operations.