So, LG Chem is making some big moves in Holland, Michigan, with a new battery factory. It’s a pretty significant investment, and it’s all part of their plan to get more batteries made right here in the U.S. for electric cars. They’ve got this new deal with Toyota, which is a pretty big deal for them, and it means they’ll be making batteries specifically for Toyota’s electric vehicles that are assembled in North America. It’s not all smooth sailing though; they’re also making some changes to their workforce at the Holland plant. Let’s break down what’s happening.

Key Takeaways

- LG Energy Solution is investing $3 billion in its Holland, Michigan facility to produce lithium-ion battery cells and modules for Toyota’s North American-assembled electric vehicles, starting in 2025.

- The new Toyota deal will give LG Energy Solution an annual battery production capacity of 20 gigawatts.

- The company is laying off 170 workers at the Holland site due to a transition to a new production facility and automakers adjusting their EV rollout speeds.

- Michigan secured this investment partly due to a $1.7 billion investment made in March 2022, which is expected to create 1,200 jobs and quintuple the plant’s capacity.

- LG Energy Solution is expanding its U.S. battery manufacturing presence through joint ventures with automakers like Hyundai, Honda, and GM, as well as building its own plants in Arizona and taking over a former GM joint venture plant in Michigan.

LG Chem’s Significant Investment in Holland, Michigan

LG Chem is making some serious moves in Holland, Michigan, and it’s a pretty big deal for the area. They’re putting a substantial amount of money into their battery production facility there. This isn’t just a small upgrade; we’re talking about a major expansion that’s set to reshape the local economy and LG Chem’s footprint in the U.S. market.

New Lithium Battery Supply Deal with Toyota

So, the big news is that LG Chem has inked a new deal to supply lithium batteries to Toyota. This partnership means Toyota’s electric vehicles, specifically those assembled right here in North America, will be powered by batteries made in Michigan. It’s a pretty significant agreement that highlights the growing demand for reliable EV battery sources within the country. This collaboration is expected to really ramp up production at the Holland plant, making it a key player in supplying batteries for a major automaker. It’s a clear sign that LG Chem is positioning itself as a go-to supplier for the electric future of the auto industry.

Expansion of Holland Campus Production Capacity

To meet the demands of this new Toyota deal, LG Chem is pumping $3 billion into its Holland campus. This investment is all about building new production lines specifically for battery cells and modules. The goal is to quintuple the plant’s current capacity, which is a massive jump. They’re aiming to have these new lines up and running by 2025. This expansion isn’t just about making more batteries; it’s about creating a dedicated, high-volume manufacturing hub right in West Michigan. It’s a move that shows a lot of confidence in the facility and the region’s ability to support such a large-scale operation. You can find out more about LG’s charging technology at LG wireless charger.

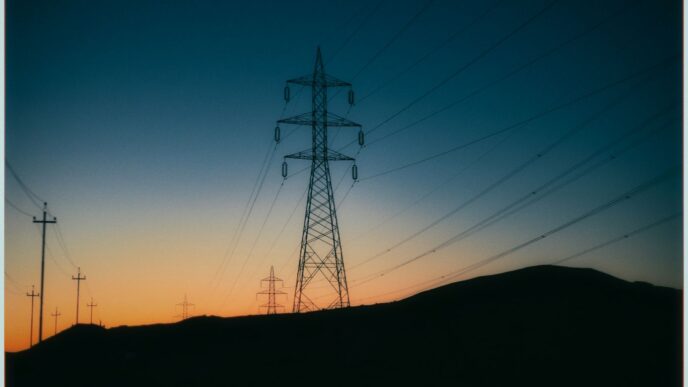

Strategic U.S. Manufacturing Network Growth

This whole expansion in Holland is part of a larger strategy for LG Chem to build out its manufacturing network across the United States. They’re not just relying on one location; they’re actively building factories and forming partnerships all over. This includes joint ventures with other big car companies like Hyundai and Honda, as well as developing their own independent factories, like the one planned for Arizona. By spreading out their operations and working with different partners, LG Chem is creating a robust and flexible supply chain. It’s a smart approach to ensure they can meet the diverse needs of the rapidly evolving electric vehicle market across the country. This strategic growth is really about solidifying their position as a leader in the U.S. battery manufacturing space.

Toyota Partnership and Production Details

LG Energy Solution and Toyota are teaming up, and it’s a pretty big deal for the Holland, Michigan plant. This partnership means LG will be supplying lithium-ion battery modules specifically for Toyota’s new electric vehicles that are built right here in North America. Think of it as a major boost for the local economy and a significant step for both companies in the EV space.

The batteries made in Holland will head to Toyota’s biggest assembly plant in Georgetown, Kentucky. This collaboration is set to kick off in 2025, and LG Energy Solution is gearing up to produce about 20 gigawatts of batteries annually. This isn’t just a small order; it’s LG Energy Solution’s largest supply agreement outside of any joint ventures they’re involved in. It really shows how much they’re investing in their North American operations.

Here’s a bit more on what this means:

- Purpose: Powering Toyota’s upcoming battery-electric vehicles assembled in the U.S.

- Production Start: Scheduled for 2025.

- Capacity: Aiming for an annual output of 20 gigawatts from the Holland facility.

- Investment: LG Energy Solution is putting $3 billion into the Holland plant to set up these new production lines exclusively for Toyota.

This move is part of Toyota’s larger plan to ramp up its EV production, aiming for 3.5 million battery EVs annually by 2030. They’re looking to keep pace with other major EV players, and securing a solid battery supply chain is key to that. It’s all about making EVs more accessible and cost-effective, which has been a hurdle for many automakers trying to grow their electric lineups.

Workforce Adjustments at the Holland Facility

LG Chem is making some big moves in Holland, Michigan, and it’s not just about building more batteries. They’ve got a new deal with Toyota, which is pretty significant for their North American operations. This means the Holland campus is getting a serious upgrade in production capacity. Think of it as a major step in growing their manufacturing network across the U.S. It’s all part of a larger strategy to be a key player in the American EV market.

Michigan’s Role in LG Chem’s Expansion

LG Chem’s big move into Holland, Michigan, isn’t just about building a new factory; it’s a major play in how the U.S. makes electric car batteries. Michigan really stepped up to make this happen, and it shows how serious they are about being a leader in the electric vehicle world. They’ve been working hard to bring big companies like LG Chem and Toyota to the state, and it’s paying off.

Securing Major Investment for Battery Facility

Michigan really rolled out the red carpet for LG Chem, securing a massive $1.7 billion investment back in March 2022. This wasn’t just a small amount; it was a huge deal for the state’s economy. This investment is a cornerstone of LG Chem’s plan to significantly boost its battery production capabilities within the United States. It’s clear that Michigan’s commitment to the electric vehicle sector made it a very attractive place for LG Chem to put its money.

Job Creation and Capacity Quintupling

This investment is expected to bring around 1,200 new jobs to Michigan, which is fantastic news for the local workforce. On top of that, the Holland facility’s production capacity is set to increase fivefold. This means LG Chem will be able to make a lot more battery components right here in Michigan, supporting the growing demand for electric vehicles.

Michigan’s Competitive Advantage for Investment

So, why Michigan? Well, it seems like the state really knows how to compete for these big projects. Other states, especially in the Southeast, and even places overseas, were also trying to get LG Chem to set up shop. But Michigan had a few things going for it:

- Existing Industry Strength: Michigan has a long history with the auto industry, so there’s already a strong foundation and a lot of know-how.

- Skilled Workforce: The state has a deep pool of workers with experience in manufacturing and automotive production, which is exactly what a battery plant needs.

- Customer Impact: Michigan’s location and infrastructure make it easier for LG Chem to get its products to its customers across North America.

It sounds like Michigan really showed it could deliver what LG Chem needed, beating out other options. Governor Gretchen Whitmer has been quoted saying that Michigan is becoming the go-to place for global companies looking to invest in the future of mobility, and this LG Chem deal certainly backs that up.

LG Chem’s Broader U.S. Battery Manufacturing Footprint

LG Energy Solution, which spun off from LG Chem in 2020, has been busy building out its presence across the United States. It’s not just about the Holland facility, though that’s a big piece of the puzzle. The company is really spreading its wings, working with some major car companies on big projects.

Joint Ventures with Major Automakers

LG Energy Solution is teaming up with several big names in the auto industry to get these battery factories up and running. They’re working with Hyundai on a massive battery manufacturing campus in Georgia, a project that’s a pretty significant investment. Then there’s the partnership with Honda for a factory in Ohio. And let’s not forget the ongoing work with GM through their Ultium joint venture, which has multiple battery production sites planned across different states. These collaborations are key to their strategy of having a strong manufacturing base right here in North America.

Independent Factory Developments in Arizona

Beyond the joint ventures, LG Energy Solution is also putting its own money into building factories from the ground up. A prime example is their large complex in Queen Creek, Arizona. This facility is set to produce different types of EV batteries, including those cylindrical ones that are becoming more common, as well as lithium iron phosphate batteries. It’s a big move for them to have a wholly-owned operation of this scale in the U.S., showing they’re serious about their independent growth too. This kind of expansion is important for companies looking to secure their supply chains, much like how Google is testing wireless charging for its self-driving cars [be0b].

Acquisition of Former GM Joint Venture Plant

LG Energy Solution has also been involved in acquiring or taking over existing operations. While the specifics can get a bit complex with joint ventures, the overall trend is that they are actively expanding their footprint. This includes taking on new facilities or increasing their stake in existing ones, which helps them grow their production capacity and market reach without starting entirely from scratch. It’s a smart way to get more batteries made for the growing electric vehicle market.

Global Market Dynamics and LG Chem’s Position

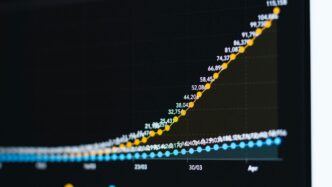

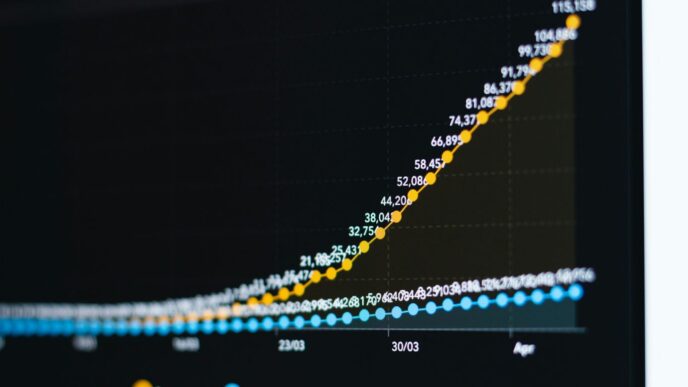

It’s a bit of a mixed bag out there for battery makers right now, and LG Energy Solution is no exception. While the push for electric vehicles is still on, the pace has slowed a bit more than some expected. This means companies like LG Energy Solution, which is a big player, have to adjust their plans. They’ve been investing heavily in places like Holland, Michigan, to build up their U.S. production, but they’re also seeing some shifts in demand.

Navigating Slower-Than-Expected EV Demand

So, what’s happening? Basically, not as many people are buying EVs as quickly as forecasts predicted a year or two ago. This isn’t just a small hiccup; it’s causing some companies to rethink their production schedules and even make workforce changes, like we’re seeing in Holland. LG Energy Solution itself reported a dip in revenue recently, partly because sales in Europe weren’t as strong as they hoped, even though North America is still doing pretty well. It’s a balancing act, trying to meet long-term goals while dealing with current market conditions. Other battery companies are facing similar issues, with some having to temporarily reduce staff at their plants due to this demand slowdown.

Comparison with Other Battery Manufacturers

When you look around, LG Energy Solution is in a crowded field. Companies like Panasonic, which has a big operation in Nevada and Kansas, are also major suppliers, especially to Tesla. Then there are Chinese companies like CATL, which is a giant in the global market. BYD is another big name, known for offering EVs at competitive prices in Europe. Each company has its own strengths and strategies. LG Energy Solution, for instance, is really focusing on building out its U.S. presence through partnerships with big automakers like Toyota, Honda, and Hyundai, as well as building its own factories. They’re aiming to be a top supplier in North America by 2030.

LG Energy Solution’s Global Market Share

Globally, LG Energy Solution holds a significant chunk of the EV battery market, around 10% or so. That’s a pretty solid position, especially considering how many companies are trying to get a piece of this pie. They’ve got factories in South Korea, China, Poland, and of course, the growing network here in the U.S. Their large facility in Poland is a big deal for the European market. The company’s strategy involves a mix of joint ventures with car manufacturers and building its own independent factories, which gives them flexibility. They’re also securing big, long-term supply deals, like the recent ones with Mercedes-Benz for their new 46-series cells, which are quite substantial orders. This diversification of production and customer base is key to their approach in this evolving market.

Looking Ahead for LG Chem in Holland

So, what does all this mean for LG Chem’s presence in Holland, Michigan? It’s a mixed bag, really. On one hand, the company is making a huge investment, a cool $3 billion, to ramp up battery production, especially with that big deal with Toyota starting in 2025. This means more batteries for electric cars being built right here in the U.S. But, it’s not all smooth sailing. We’ve also seen some layoffs, which the company blames on a temporary production gap and automakers adjusting their EV plans. It seems like the electric vehicle market is still finding its footing, and companies like LG Chem are having to adjust their operations. Still, Michigan seems to be a key spot for this kind of manufacturing, and LG Chem has been a big part of the Holland community for a while now. It’ll be interesting to see how they navigate these changes and continue to grow in the evolving world of electric vehicles.