The world is changing fast, and how we get our energy and power our lives is a big part of that. We’re seeing some really cool new ideas pop up that are making things cleaner and better for the planet. From how we capture sunlight and wind to storing power and even making materials, there’s a lot happening in the world of clean tech. It’s all about finding smarter, more sustainable ways to do things, and it’s pretty exciting to see where it’s all headed.

Key Takeaways

- New solar tech, like perovskites and building-integrated panels, is making solar power more efficient and useful in cities.

- Wind turbines are getting bigger and smarter, with offshore farms and better maintenance helping them produce more power reliably.

- Better battery storage and other methods are key to making sure we have renewable energy available all the time, not just when the sun is shining or the wind is blowing.

- Smart grids and AI are helping manage our energy use better, making the whole system more flexible and efficient for everyone.

- Green hydrogen and new materials are starting to clean up tough industries like shipping and construction, reducing their environmental impact.

Next-Generation Solar Systems Reshaping Clean Tech

Solar is having a second growth spurt. Panels aren’t just getting better; they’re showing up in new places and doing double-duty with land and water.

Next‑gen solar isn’t only about higher efficiency—it’s about putting clean power where it works best.

Perovskites and Tandem Cells Pushing Efficiency Limits

Perovskites are the buzzy newcomer because they soak up light well and can be printed at low temps. Pair them with tried‑and‑true silicon and you get tandem cells that grab more of the solar spectrum. Lab records keep getting broken, but the big test is how these stacks hold up in heat, humidity, and years of UV.

What’s getting traction now: better encapsulation, 2D/3D perovskite mixes to slow decay, and manufacturing methods like slot‑die coating that could scale fast. There’s also the lead question; serious players design strict capture and recycling so nothing leaks into soil or water.

Key points:

- Tandem cells aim to lift module efficiency from ~21–23% (premium silicon) toward 26–30% this decade.

- Lower energy input for perovskite layers could cut costs if reliability matches silicon’s 25+ year record.

- Bankability hinges on passing damp‑heat, thermal‑cycle, and UV tests with low annual degradation.

| Technology | Typical Module Efficiency (today) | Near‑Term Target | Notes |

|---|---|---|---|

| Crystalline silicon (PERC/TOPCon/HJT) | 20–23% | 24–25% | Mature, low degradation ~0.2–0.5%/yr |

| Perovskite single‑junction | 15–20% (pilot) | 22–25% | Needs stability gains and scale |

| Perovskite‑silicon tandem | 22–25% (early pilots) | 28–30% | Highest upside if durability proven |

Building-Integrated Photovoltaics Powering Cities

BIPV turns surfaces—roofs, facades, skylights—into power plants. It’s not just slapping on panels; the solar is the building material. That means fewer racking parts, cleaner lines, and sometimes better local approvals. The tradeoff is usually lower power density, tougher fire and wind rules, and more coordination between electricians, architects, and inspectors.

Where BIPV makes sense:

- New builds that can design wiring, fire breaks, and mounting from day one.

- Retrofits where facade or roof replacement is already budgeted.

- Sites with strict aesthetics or limited roof space.

| BIPV Type | Power Density (W/m²) | Best Use |

|---|---|---|

| Solar shingles/tiles | 100–180 | Residential roofs needing clean look |

| Semi‑transparent PV glass | 50–150 | Facades, skylights, atriums |

| PV facade cladding | 120–200 | Mid/high‑rise exteriors, carports |

Tips that save headaches:

- Lock in fire rating (e.g., Class A roof assemblies) and wind/snow load calcs before procurement.

- Model shading from parapets and nearby buildings; facades need realistic yield estimates.

- Plan for access paths and replaceable sections so maintenance doesn’t require scaffolding every time.

Agrivoltaics and Floating Arrays Optimizing Land and Water

Agrivoltaics share fields with crops or grazing. Panels add shade and wind buffering, which can cut water stress and even lift yields for shade‑tolerant plants in hot regions. You’ll need taller racking, wider spacing, and sometimes trackers that keep light even. Farmers care about gates, equipment clearance, and simple O&M more than anything.

Floating PV sits on ponds and reservoirs. The water cools modules, so output can tick up, and covering part of the surface can reduce evaporation. Anchors and corrosion control matter a lot, and you’ll want a good plan to protect wildlife and water quality.

What to expect in practice:

- Agrivoltaics: potential 5–20% yield gains on shade‑tolerant crops and meaningful water savings in arid climates; watch for tractor access and soil compaction.

- Floating PV: 5–15% energy yield boost from cooler temps and notable evaporation cuts on the covered area; design for storms and biofouling.

- Both formats trade some simplicity for co‑benefits—land efficiency for farms, water savings for utilities.

| Format | Standout Benefit | Design Watchouts |

|---|---|---|

| Agrivoltaics | Crop resilience, water savings, dual income | Height/spacing, farm logistics, livestock safety |

| Floating PV | Higher yield per kW, less evaporation | Anchoring, corrosion, environmental permits |

| Ground‑mount (baseline) | Lowest complexity, broad vendors | Land use conflicts, visual impact |

Wind Power Reinvented With Advanced Turbines and Design

I used to think wind turbines were just big fans with a plug. Then I watched a crew assemble a modern machine and realized it’s more like a flying wing on a 150-meter stick, run by software that never sleeps. The designs keep getting smarter, and the gains add up day after day.

Here’s a quick snapshot of where turbine design stands right now:

| Design type | Typical size (2025) | Capacity factor | Notes |

|---|---|---|---|

| Onshore | 3–6 MW, 130–170 m rotor | 35–45% | Quiet, optimized for low-wind sites |

| Fixed-bottom offshore | 8–15 MW, 170–220 m rotor | 45–55% | Shallow to mid-depth waters |

| Floating offshore | 10–20 MW, 200–260 m rotor | 45–60% | Deep waters, larger sites |

Taller Turbines and Blade Innovations Boosting Yield

Taller towers reach steadier winds that don’t stall out as often. Longer blades sweep more air, which boosts output without needing more wind. Materials are changing too: carbon fiber in the blade’s backbone, lighter resins, and smarter aerodynamics along the trailing edge.

Bigger rotors and smarter controls squeeze more electricity out of the same wind.

What’s actually changing on the hardware and controls side:

- Segmented blades for easier transport to remote sites.

- Serrations and vortex gizmos that cut noise and keep airflow attached.

- Lidar on the nacelle to “see” gusts seconds before they hit, adjusting pitch proactively.

- Wake steering between turbines, so upstream machines nudge their wakes away from neighbors.

- Grid-friendly inverters that steady voltage and ride through faults.

The result isn’t flashy on a single day, but across a year, higher capacity factors mean more clean electricity from fewer machines—good for landowners and the grid.

Offshore Platforms and Floating Wind Expanding Access

Offshore used to mean fixed foundations close to shore. Now we’re talking larger machines in deeper water. Semi-submersibles, spars, and tension-leg platforms open up windy areas where the seabed drops off fast. Mooring lines spread loads, and dynamic cables move with waves without tearing apart. Ports and vessels are scaling up to handle nacelles the size of houses.

There’s also some cross-pollination from other tech fields. Advanced sensors, autonomy, and even augmented views—ideas you’ll see in concept cars like the BMW Vision Vehicle—are creeping into offshore planning and operations. Think better situational awareness for crews and smarter navigation for installation vessels.

Three things pushing costs down offshore:

- Bigger turbines mean fewer foundations per megawatt.

- Standardized floating hulls built in series, not one-off prototypes.

- Better wind resource models, so projects land in the sweet spot between high wind and workable seas.

New designs have to handle tough weather. Typhoon-class blades, anti-icing coatings, and tuned controls keep loads within limits so gearboxes and bearings live longer.

Predictive Maintenance and Robotics Extending Turbine Lifetimes

If you’ve ever watched a tech hang from a blade, you know maintenance is no joke. Today, most checks happen without stopping the turbine. Sensors track vibration, temperature, and oil quality. Software flags patterns that hint at early wear, so crews fix the small stuff before it becomes downtime.

Robotics are doing the risky climbs. Drones map blade cracks in high resolution. Crawlers sand and patch leading edges. Underwater ROVs inspect monopiles and moorings without divers. Over time, better coatings and gentler control strategies also stretch the years between major repairs.

A practical maintenance playbook looks like this:

- Start with a digital twin—basically a live model tied to sensor data.

- Set thresholds for vibration, temperature, and power curves; alert early, not late.

- Use drones after storms and during seasonal blade checkups.

- Schedule minor blade repairs immediately; waiting makes damage spread fast.

- Keep a spare-parts plan for slow-to-source items like main bearings and power electronics.

All of this adds up to fewer surprise outages, steadier output, and turbines that can run well into the high twenties for service life. It’s not magic. It’s a smarter mix of design, data, and real-world field work that respects the weather and the people doing the job.

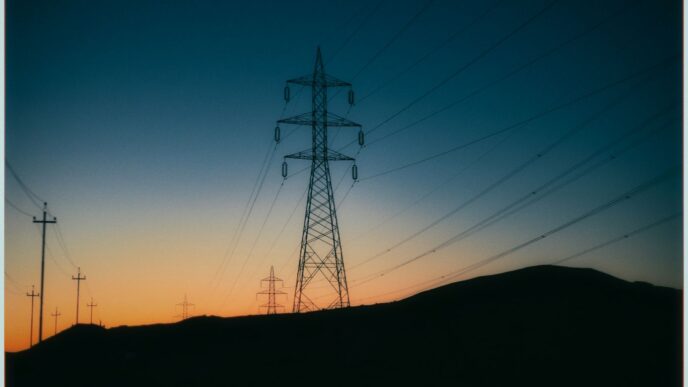

Breakthrough Energy Storage Enabling Round-the-Clock Renewables

Energy storage is the bridge that makes wind and solar behave like 24/7 power.

We’ve all watched a sunny afternoon turn into a cloudy evening and seen wind die right when folks get home and flip everything on. The grid needs backup that kicks in fast and lasts as long as the weather decides to be moody. That’s where a new wave of storage comes in—longer duration, tougher chemistry, and smarter reuse of batteries we already have.

| Storage type | Typical discharge (h) | Round-trip efficiency (elec→elec) | Cycle life (full cycles) | Best-fit use case |

|---|---|---|---|---|

| Lithium-ion (LFP) | 2–6 | 85–92% | 3,000–8,000 | Daily solar shifting, grid services |

| Long-duration (iron-air, Na–S) | 10–100 | 45–70% | 1,000–10,000 | Multi-day wind/solar lulls, resilience |

| Flow (vanadium, Zn–Br, organic) | 4–20+ | 70–85% | 10,000–20,000 | Heavy cycling, long hours |

| Thermal (molten salt, hot rocks) | 6–20+ (electric), hours–days (heat) | 30–50% (electric), high for heat use | n/a | Industrial heat, district energy, CSP |

| Second-life EV packs | 1–4 (typical) | ~80–90% (pack/BMS dependent) | +1,500–4,000 (after grading) | Buildings, community storage, mobile power |

Long-Duration Batteries Advancing Grid Reliability

Short batteries cover the evening peak. The hard part is the 2–3 day slump when clouds park over a region and the wind is lazy. Long-duration energy storage (LDES) tackles that gap.

What’s moving fast:

- Iron-air and other metal-air systems: cheap, abundant materials, 50–100-hour discharge is the aim; lower efficiency, but very low energy-side cost makes multi-day storage realistic.

- Sodium–sulfur: proven at utility scale, 6–12-hour blocks, high operating temperature but compact and long-lived.

- Next-gen Li-based (LFP/LMFP) and sodium-ion: safer cathodes, better lifetime, and lower cost per kWh; pushing 6–8 hours without exotic materials.

Why grid planners care:

- Provides clean “firm” capacity during long wind or solar slumps.

- Cuts curtailment by soaking up midday oversupply and releasing for long peaks.

- Relieves congested transmission by time-shifting power across hours or days.

- Supports black-start and microgrids during storms and wildfire shutoffs.

Practical notes:

- Power-to-energy ratio matters: 1 MW with 100 MWh is a different tool than 10 MW with 10 MWh. Design for the actual weather pattern you’re covering.

- LCOS (levelized cost of storage) wins come from cheap energy capacity, modest efficiency needs, and high utilization—multi-day use cases fit that bill.

Flow Batteries and Thermal Storage Scaling Flexibility

Flow batteries store energy in liquid electrolytes and scale by adding tanks. You choose your power (stacks) and your hours (tank size) separately, which is handy and often cheaper for long durations.

Where flow shines:

- 10k–20k cycle lifetimes with little degradation; great for daily and intraday cycling.

- Easy to extend duration from 4 to 12+ hours by upsizing tanks.

- Non-flammable electrolytes in many designs simplify siting and safety.

Thermal storage takes a different route—store heat first, then use it as heat or convert back to power.

- Media: molten salts, hot water, sand/rock/brick beds at 120–1,000°C.

- Best when you can use heat directly for steam, drying, or district energy.

- If you need electricity back, pair with turbines or high-temp heat engines; round-trip efficiency is lower, but the energy cost is often very low.

When to pick what:

- Flow batteries: frequent cycling, long life, 6–20+ hours without expanding interconnects.

- Thermal storage: factories and cities that already use lots of heat; CSP retrofits; heat-pump + tank combos for buildings.

- Hybrid sites: combine flow or thermal with short-duration Li-ion for fast response plus long hours.

Second-Life EV Batteries Creating Circular Storage

EV packs don’t “die” at 70–80% state-of-health; they retire from cars. Stationary storage is less demanding, so those packs can work a second shift.

Typical repurposing path:

- Intake and grading: read the battery history, test cells/modules, sort by health.

- Refurbish: replace weak modules, update the BMS, add fire detection and isolation.

- Repack: assemble standardized racks with fuses, contactors, and cooling.

- Certify: safety testing to recognized standards; clear labels and data sheets.

- Deploy: behind-the-meter, community batteries, or temporary power at sites.

Where second-life fits best:

- Buildings shaving demand charges and backing up critical loads.

- Community storage soaking up neighborhood solar and easing evening peaks.

- Mobile and seasonal jobs: events, construction sites, farm loads.

What to watch:

- Warranty and data access: good records make projects financeable.

- Traceability and recycling: design racks so modules are easy to remove later.

- Economics: pilots report 30–50% lower pack cost than new, with 5–10 years of useful life depending on SoH and duty cycle.

Bottom line: pair short, long, and repurposed batteries with thermal options, and the grid stops caring whether it’s windy or sunny at this exact minute.

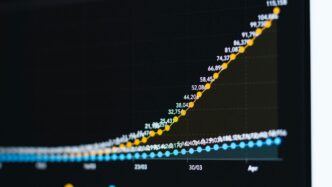

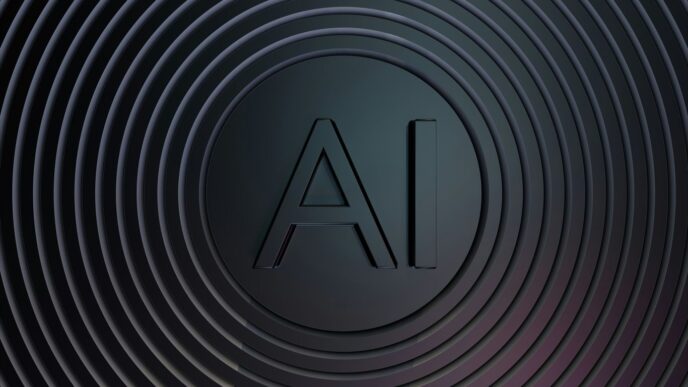

Smart Grids and AI Orchestrating a Flexible Clean Tech Grid

The grid is getting a brain. Sensors, software, and a wave of small devices now feed data from homes, streets, and substations. AI turns a patchy, one-way power network into something that balances supply and demand minute by minute. That’s the big shift—steadier power, fewer surprises, and room for lots more wind, solar, and EVs.

| Metric | Yesterday’s grid | AI-optimized grid |

|---|---|---|

| Forecast error (day-ahead) | 15–20% | 5–8% |

| Outage isolation time | 80–120 min | 20–40 min |

| Control response time | Minutes | Seconds |

| Curtailment during peaks | High | Low |

Edge Intelligence and IoT Enabling Real-Time Optimization

Edge devices—smart meters, line sensors, inverters, and EV chargers—make tiny decisions locally, fast. They don’t wait for a central command if the voltage sags or a cloud rolls over a solar farm. The spread of the Internet of Things is what makes this possible: millions of small data points, cleaned and acted on at the grid’s edge.

What actually runs at the edge today:

- Grid sensors spot abnormal current and flag faults before a feeder trips.

- Inverters tweak reactive power to hold voltage within safe bounds.

- EV chargers ramp down when a neighborhood transformer gets close to its limit.

- Building controllers pre-cool or pre-heat when cheap wind is forecast for the next hour.

- Microgrids island during a disturbance, then resync when the main grid is stable.

Why it matters: faster feedback cuts losses, reduces outages, and trims the cost of integrating variable renewables.

Virtual Power Plants Unlocking Distributed Energy

A virtual power plant (VPP) links thousands of small assets—home batteries, smart thermostats, commercial HVAC, EVs—and coordinates them like a single resource. Instead of building a new peaker plant, you tap flexible load and storage that already exists.

How a VPP run might look in practice:

- Enrollment: homes and businesses opt into a program with clear limits and incentives.

- Forecast: software predicts solar output, demand spikes, and available flexibility.

- Bidding: the VPP offers capacity (kW) or energy (kWh) into a market or utility event.

- Dispatch: devices discharge, charge slower, or shift usage for 1–4 hours.

- Settle: participants get paid, and the system logs performance for the next event.

A 50 MW VPP might come from 40,000 households contributing 1–2 kW each, plus a handful of commercial sites. The upside is not just cheaper peaks; it’s also lower emissions because you avoid firing up the dirtiest generators.

Demand Response and Dynamic Pricing Empowering Consumers

Prices that change by time—hourly or by blocks—nudge the system to use power when it’s clean and cheap. Smart water heaters, thermostats, and EV chargers can follow simple rules: shift to off-peak, avoid critical peaks, and soak up excess solar at midday. Most people don’t want to babysit their devices, so automation does the heavy lifting.

A simple playbook for households and small businesses:

- Pick a rate that matches your routine (time-of-use or real-time pricing).

- Set your thermostat with a modest pre-cool or pre-heat window.

- Schedule EV charging after midnight or at midday solar peaks.

- Let your water heater run during low-cost hours with a small temperature buffer.

- Join a demand response program with clear opt-out rules for comfort.

On the utility side, better price signals and fair incentives help cut peak demand, trim bills, and reduce strain on feeders. The result is a cleaner grid that feels boring—in a good way—because it just works, even on the hottest day of the year.

Green Hydrogen and Power-to-X Fueling Hard-to-Decarbonize Sectors

Green hydrogen is made by splitting water with clean electricity. Power-to-X turns that hydrogen into other products like ammonia, e-methanol, or e-kerosene. This combo goes after emissions in steel, fertilizers, shipping, and aviation where batteries fall short.

High-Efficiency Electrolyzers Driving Cost Parity

Electrolyzers are getting cheaper, larger, and more flexible. The biggest cost driver is electricity, which can be 60–80% of green hydrogen’s price. So, low-cost power and smart operation hours matter as much as the hardware.

Key shifts happening now:

- Higher current densities and bigger stacks cut capex per kilogram of H2.

- Better membranes and catalysts aim to reduce precious metals in PEM units.

- High-temperature SOECs tap waste heat from industry to raise efficiency.

- Pressurized operation trims compression costs downstream.

Typical electrolyzer profiles (indicative ranges):

| Technology | Efficiency (LHV) | Capex (2025, $/kW) | Response | Best Fit |

|---|---|---|---|---|

| Alkaline (AEL) | 55–65% | 500–900 | Seconds–minutes | Steady, low-cost power, large plants |

| PEM | 55–70% | 800–1,400 | Sub-second–seconds | Fast-ramping with wind/solar |

| SOEC (high-temp) | 75–85% (with heat) | 1,000–2,000+ | Minutes | Sites with high-grade heat, e-fuel plants |

Where costs are landing:

- Today’s green H2: roughly $3–6/kg in many markets (wind/solar-rich sites are lower).

- Parity with gray H2 is often pegged near $1–2/kg, depending on gas prices.

- Path to get there: cheap renewable power (2–3¢/kWh), high utilization, better stacks, and policy credits (like 45V in the U.S.).

Ammonia and E-Fuels Decarbonizing Shipping and Aviation

Ammonia is gaining traction for ships because it carries hydrogen without carbon at the point of use. Engines and fuel cells that burn ammonia still need NOx control and careful handling, since it’s toxic. The upside: global trade already moves ammonia, and storage is easier than liquid hydrogen.

Aviation is a different puzzle. E-kerosene (synthetic jet fuel) slots into today’s planes and engines after blending and certification. It’s made from green hydrogen plus captured CO2. It’s pricey right now, but the drop-in fit is a big deal.

Quick snapshot (directional values):

| Fuel | GHG Reduction vs Fossil (lifecycle) | 2025 Cost Signal | Notes |

|---|---|---|---|

| Green Ammonia (NH3) | ~60–90% | $700–1,200/ton NH3 | Needs NOx control; ship engines maturing |

| E-Methanol | ~60–95% | $600–1,200/ton | Used in next-gen ships; simpler storage |

| E-Kerosene (SAF) | ~70–95% | $4–8/gal | ASTM pathways; blends today, higher shares later |

What helps these fuels scale:

- Round-the-clock hydrogen via baseload renewables, storage, or grid contracts.

- Heat integration (great with SOEC) to lift plant efficiency.

- CO2 offtake from biogenic sources or direct air capture for e-fuels.

- Clear fuel standards, NOx limits for ammonia engines, and long-term offtake deals.

Hydrogen Hubs Linking Renewables and Industrial Loads

Hydrogen hubs bundle production, storage, transport, and big users in one region. Think wind and solar feeding electrolyzers, salt caverns holding weeks of hydrogen, and pipelines or trucks sending it to steel, fertilizer, refineries, and ports.

What a working hub usually includes:

- Large, cheap clean power plus water supply and permits.

- Centralized electrolyzers sized for high run hours.

- Storage (salt caverns where geology allows; otherwise tanks or LOHCs).

- Shared pipelines, compression, and refueling depots.

- Anchor customers with multi-year contracts (ammonia, steel, SAF plants, heavy trucks).

Practical steps that cut risk:

- Start with one or two anchor loads that can take most of the output.

- Add storage first; it smooths curtailment and keeps plants running.

- Build pipelines last, after volumes are proven; use tube trailers early on.

- Co-locate with process heat users to favor SOEC where it makes sense.

- Track a short list of KPIs: electrolyzer capacity factor, LCOH, storage days, leak rate, and delivered-fuel price.

Policy tailwinds to watch:

- Production tax credits tied to verified carbon intensity.

- Contracts for difference or price floors to steady early projects.

- Clear rules for what counts as “renewable” power and time-matching.

Bottom line: green hydrogen and Power-to-X won’t replace electrons in every case, but they give heavy industry, ships, and planes a path forward without fossil fuels.

Circular Manufacturing and Low-Carbon Materials Elevating Clean Tech Supply Chains

Circular manufacturing cuts waste and carbon while saving money, and it’s finally scaling.

Clean tech gear—turbines, panels, batteries—runs on heavy stuff like steel, cement, aluminum, and plastics. Most emissions hide in the supply chain, not at the project site. The fix isn’t one magic material; it’s smarter design, low-carbon feedstocks, and more loops for repair and reuse. Buyers have real pull here: switch specs from “what it’s made of” to “what it must do,” and suppliers start showing up with better mixes and lower-footprint parts.

Low-Carbon Cement and Steel Reducing Industrial Emissions

Cement and steel are the heartbeat of clean energy projects and also big emitters. The good news: proven routes can cut their footprints now.

- Cement moves first by swapping clinker with supplementary materials (fly ash, slag, calcined clay/LC3), tuning mix design, and using better curing. CCUS and kiln electrification are coming up fast in pilots, but availability varies by region.

- Steel drops fast when you use scrap in electric arc furnaces (EAF) with clean power. New direct-reduced iron (DRI) plants using hydrogen feed near-zero pathways, though they need steady renewable electricity.

- For buyers: request environmental product declarations (EPDs), set performance specs (compressive strength, durability) instead of recipe mandates, and source nearer to site to cut transport.

| Material | Conventional CO2e (tCO2e per t) | Lower-carbon route (near-term) | CO2e range (tCO2e per t) |

|---|---|---|---|

| Cement | 0.6–0.9 | SCM/LC3 blends, optimized mixes | 0.4–0.6 |

| Steel | 1.8–2.3 | Scrap-based EAF with clean power | 0.3–0.6 |

| Steel (next) | 1.8–2.3 | H2-DRI + EAF (renewable power) | 0.1–0.4 |

Practical tips you can act on this quarter:

- Replace prescriptive mixes with performance-based specs and cap EPD intensity (e.g., kg CO2e/m³ concrete).

- Design lighter structures: fewer materials, same safety. Often a quick win with good engineering.

- Lock in “green steel” or LC3 through offtake deals so supply actually shows up when you build.

Modular Design and Remanufacturing Extending Product Life

If it comes apart cleanly, it can be repaired, upgraded, and sold again. That’s cheaper than new and faster than waiting on long lead times.

- Design rules that pay off:

- Standard fasteners and minimal adhesives.

- Clear labeling on parts and materials for sorting.

- Swappable subassemblies (power electronics, bearings, battery modules).

- Firmware that accepts new modules without drama.

- Digital product passports to track parts, cycles, and warranties.

- Good candidates: inverters, turbine gearboxes, pitch systems, EV drive units, and battery packs. These see predictable wear and can be factory-refreshed.

- Metrics that keep programs honest:

- Parts reuse rate (% by cost)

- Turnaround time vs. new

- Failure rate in field vs. new

- CO2e saved per refurbished unit

One workable loop: collect cores with a deposit, grade them at a regional hub, remanufacture high-value modules first, and feed the rest to parts harvest and certified recycling. Warranty the reman unit like-new, or people won’t touch it.

Advanced Recycling and Bio-Based Polymers Replacing Virgin Plastics

Plastics are everywhere in clean tech—cable insulation, housings, films. Virgin resin carries a heavy footprint. Two tracks are moving fast: better recycling and bio-based options.

- Mechanical recycling works when parts are clean, single-polymer, and lightly colored. It’s cheap and low-carbon but can drop properties.

- Advanced recycling helps with mixed streams:

- Depolymerization (great for PET, nylon): back to monomers with near-virgin quality.

- Solvent-based dissolution: removes additives and color, keeps polymer chains.

- Pyrolysis: turns mixed PE/PP into oil, then back into resin via mass balance systems.

- Bio-based polymers:

- Drop-in types (bio-PET, bio-PA) keep performance and integrate easily.

- New families (PLA, PHA) fit select parts, but heat and durability need attention.

| Option | Typical GHG change vs. virgin | Best fits | Watch-outs |

|---|---|---|---|

| rPET (mech) | 40–70% lower | Housings, trays | Color/quality varies |

| PET depolymerized | 60–80% lower | Films, high-spec parts | Higher cost, limited capacity |

| rPP/PE (mech) | 30–60% lower | Cable ducts, covers | Odor, property drift |

| Pyrolysis-based PE/PP | 40–70% lower | Food/medical-grade needs | Energy intensity, certification |

| Bio-PET | 20–40% lower | Bottles, durable parts | Feedstock sourcing |

| PLA/PHA | 30–70% lower | Trays, trims | Heat resistance, end-of-life |

Make it work at scale:

- Design for recyclability: mono-material parts, no dark pigments, easy-to-remove labels.

- Specify minimum recycled or bio-based content with third-party certification (ISCC PLUS, UL, or equivalent).

- Set up take-back for end-of-life components and write end-of-life into supplier contracts.

Bottom line: cleaner inputs plus products built to be taken apart beat one-way supply chains. It’s not flashy, but it sticks, and it cuts both cost and carbon over time.

Electrified Mobility and Charging Ecosystems Accelerating Clean Tech Adoption

Electric transport isn’t just about zippy cars anymore. It’s chargers on every corner, smarter software, and batteries that don’t flinch at winter mornings. The pieces are finally clicking together, sometimes awkwardly, but fast enough that gas stations are starting to feel a little old.

Ultra-Fast Charging and Bidirectional Power Integration

Ultra-fast DC chargers (150–350 kW) paired with 800V vehicle platforms cut wait times way down. In perfect conditions, many new models can jump from 10–80% in about 15–30 minutes. Real life is messier—charge taper, cold packs, and crowded stations get in the way—but preconditioning and smarter routing help a lot. Bidirectional charging turns parked EVs into helpful batteries for homes and the grid.

| Charging mode | Typical power (kW) | 10–80% time (77 kWh pack) | Common use |

|---|---|---|---|

| Level 2 AC | 7–11 | 300–420 min | Home/workplace |

| DC Fast | 100–200 | 25–45 min | Highway, urban hubs |

| DC Ultra-fast | 250–350 | 12–25 min | High-throughput corridors |

What makes bidirectional work in the real world:

- Vehicle + charger standards (ISO 15118-20, CCS updates) so cars and stations speak the same language.

- Tariffs that pay for timing (sell during peaks, charge when cheap) without surprise fees.

- Aggregation software to manage thousands of cars, limit battery wear, and follow grid rules.

- Hardware that’s homeowner-friendly: automatic transfer switches and clear backup modes (V2H), plus workplace and fleet options (V2B/V2G).

Typical V2H power today is 3.6–11 kW, plenty to cover a fridge, lights, and some HVAC. Many EVs store 60–100 kWh, which can keep a house running for a day or two if you’re careful.

Battery Chemistry Innovations Extending Range and Safety

LFP batteries are spreading beyond entry-level models thanks to long cycle life and stable behavior; the tradeoff is lower energy density. Nickel-rich chemistries (NMC/NCA) still win on range but need tight thermal control and better sourcing. Silicon-heavy anodes are creeping in, trimming charge times while managing swelling. Solid-state is the next big swing—higher energy per kilogram and better safety on paper—but scaling factories and quality control is the hard bit. Sodium-ion looks promising for budget cars and scooters, with decent cold-weather gains and simpler materials.

What drivers actually feel from all this:

- Longer range without bigger price tags as pack-level energy creeps from ~180–200 Wh/kg to ~220–260 Wh/kg in mainstream models.

- Better fast-charge repeatability from improved electrolytes, pack cooling plates, and 800V architectures.

- Lower costs from cobalt-light chemistries (LFP, manganese-rich cathodes) and higher-yield manufacturing; sub-$100/kWh packs are appearing in some LFP supply chains.

- More robust packs: cell-to-pack designs, thermal propagation barriers, and smarter BMS that throttle fast charging when cells need a breather.

- Clearer warranties (often 8 years/100,000 miles) and data showing shallow daily cycles barely touch long-term health.

Transit Electrification and Micromobility Cutting Urban Emissions

City air gets cleaner fastest when buses, delivery vans, and two-wheelers go electric. Depot charging suits overnight schedules; on-route pantographs (300–600 kW) top up in minutes at end stops. E-buses typically carry 300–500 kWh packs and can cover 100–200 miles a day, while maintenance savings stack up because there are fewer moving parts than diesel. Meanwhile, e-bikes and scooters sip energy—roughly 0.5–1 kWh for 20 miles—making short trips cheap and quiet.

What forward-looking cities and fleets are doing now:

- Converting bus routes in phases, pairing each route with the right charger mix (depot AC, on-route DC) and software that plans charge windows.

- Updating building codes so new parking comes pre-wired for a high share of Level 2 ports.

- Rolling out curbside charging in dense neighborhoods and making it reliable, not just installed.

- Bulk-buying e-buses and vans with long-term service plans, then training mechanics on high-voltage systems.

- Supporting safe micromobility with UL-certified batteries, better storage rules, and simple fire-safe charging rooms.

- Using open data so apps can tell drivers which chargers work, what they cost, and whether they’re free right now.

The big picture: if charging stays simple, batteries keep getting sturdier, and fleets lock in long-term plans, the switch to electric transport starts to feel normal—not flashy, just part of daily life.

Looking Ahead: A Sustainable Future Powered by Innovation

So, we’ve talked a lot about all the cool new tech coming out, from solar panels that work better to cars that run on electricity. It’s pretty clear that innovation is really driving us toward a cleaner planet. We’re seeing big changes in how we get our energy and how we get around, and that’s a good thing. It’s not always easy, and there are still hurdles to jump, like making sure everyone can afford these new technologies and building the right infrastructure. But the progress we’re making is undeniable. By continuing to support and develop these green solutions, we’re really setting ourselves up for a healthier world for everyone, now and for the future.