Understanding Why Robot Is Important in 2025

The Evolution from Simple Automation to Intelligent Systems

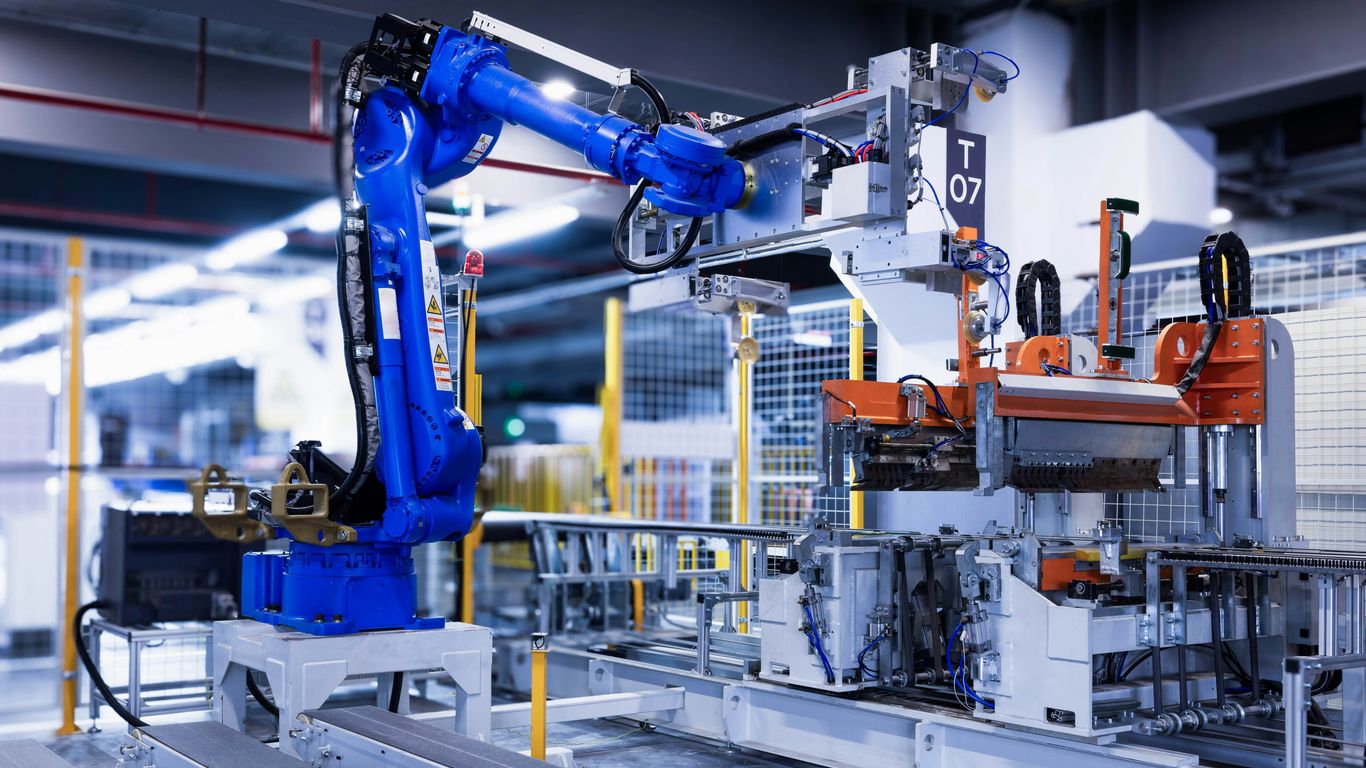

Let’s rewind a bit. When robots started showing up in factories decades ago, they were nothing like what we have in 2025. The earliest machines—mostly just stiff mechanical arms—did repetitive tasks and stayed in one spot. They worked on straightforward things like welding or putting together car parts. Over time, robotics got smarter, thanks to better software and sensors. Now, robots are not just tools but can actually make their own decisions and handle surprises. This huge leap from basic automation to thinking machines has changed the rules for businesses everywhere.

Here’s a quick look at their journey:

- First-generation robots: Fixed, did one thing, perfect for assembly lines in cars or electronics

- Second wave: More sensors and a bit of programming, could stop if something went wrong

- Today: Intelligent systems that adjust on the fly, work with people, and learn from mistakes

Advancements in Artificial Intelligence and Adaptability

What really sets 2025 apart is how robotics and artificial intelligence work together. Now robots can figure things out, tweak their behavior, and constantly improve from the data around them. Most factories and even homes have gadgets that predict your needs or adapt when something unexpected happens. Big tech companies have launched all kinds of AI-driven robots and smart systems, especially since everyone wants smarter, safer, and more efficient solutions.

Here’s what makes new robots different:

- They learn from patterns and past mistakes (machine learning)

- They handle more than one job and can move between tasks

- They play nice with people, which cuts down on accidents and gets more done

A simple table shows this progress:

| Era | Type of Robot | What They Could Do |

|---|---|---|

| 1960s-1980s | Mechanical Arms | Repetitive, fixed tasks |

| 1990s-2010s | Automated Systems | Pre-programmed, basic safety |

| 2025 | Intelligent Robots | Learn, adapt, collaborate |

Widespread Integration Across Industries

Now, robots aren’t just tucked away in big factories. They show up everywhere: kitchens, hospitals, delivery trucks, construction sites, and even classrooms. Robots in 2025 help with everything from filling in for labor shortages to making sure goods get delivered fast. They can check a heart rate in a hospital one minute and stack groceries the next.

Here are a few reasons why robots matter so much now:

- Faster, safer production and fewer on-the-job injuries

- Help with jobs people don’t want or can’t do (especially in risky places)

- New career paths in robotics tech, maintenance, and support

- Reduce waste and save energy—robots don’t get tired or distracted

Looking back, it’s clear that robots in 2025 aren’t just background tech—they’re front and center, making daily life smoother and work less risky, more efficient, and sometimes even a little more fun.

Revolutionizing Industry and Manufacturing with Robotics

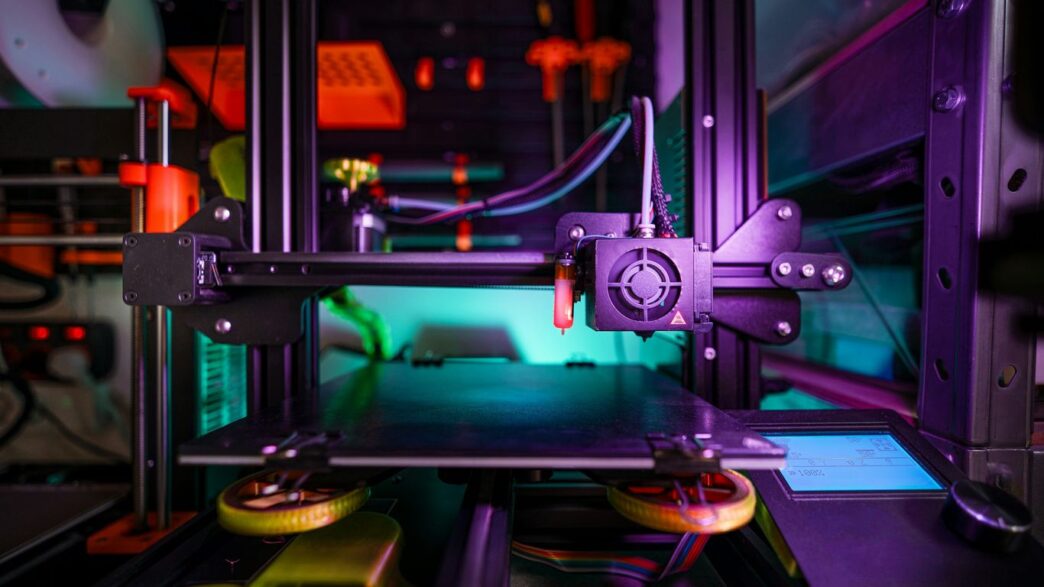

The world of manufacturing in 2025 looks so different from just a few years ago, and robots have a lot to do with that. These machines have completely changed how factories work—taking on tough, tedious tasks while helping people work smarter, not harder.

Unmatched Precision in Assembly and Quality Control

If you’ve ever watched a robot assemble tiny parts in electronics or weld car panels, you know how exact they are. Modern robots deliver levels of accuracy that humans just can’t match, especially for repetitive jobs. This isn’t just about speed. It seriously closes the gap on mistakes and faulty products, which saves manufacturers a ton of money.

Here’s a quick look comparing error rates:

| Task | Manual Labor Error Rate | Robotic System Error Rate |

|---|---|---|

| Microchip Placement | 2.5% | 0.1% |

| Car Panel Welding | 1.1% | 0.03% |

| Electronic Testing | 3.2% | 0.2% |

Even in inspection, cameras and sensors catch stuff the human eye just misses. Out of thousands of products, catching a single flaw is no problem for these systems.

Enhancements in Workplace Safety and Hazardous Environments

One major reason companies lean on robots? They don’t get tired, and they don’t get hurt—instead, they take on risky work no one wants. Think about situations like these:

- Handling toxic chemicals

- Working near heavy, dangerous machinery

- Operating in extreme temperatures

Not only does this keep people safer, but it also means less downtime from accidents. Fewer injuries mean fewer workdays lost and much lower insurance costs for business owners.

Efficient Logistics and Inventory Management

Warehouses are nothing like they used to be. Autonomous robots now zip around, fetching products, stacking shelves, and even handling shipping preparations. This sorting and inventory work used to slow everything down, especially when workers struggled to keep up during busy seasons.

Here’s what robots now manage each day in the average large warehouse:

- Tracking thousands of inventory items in real-time

- Moving pallets and goods between zones

- Sorting packages by destination

- Loading and unloading materials

This has shortened delivery time and made inventory way less of a headache. Customers expect same-day delivery these days, and robots make that possible.

The Rise of Collaborative Robots (Cobots)

Cobots are the new team members on a lot of factory floors. Instead of keeping people and robots separated with cages or barriers, these cobots work right next to humans. They lend an extra pair of hands for lifting, guiding, or tightening.

Cobots stand out because:

- They’re easy to program—even for someone who’s never coded before.

- They adjust in real-time, moving out of the way if people come close.

- They take on boring, repetitive jobs, freeing humans for more interesting work.

Unlike old robots that needed whole teams just to keep running, these new machines are plug-and-play. They’re changing what it means to have a job in manufacturing, making work less exhausting and more interesting.

Overall, the shift is huge—robots in 2025 aren’t just tools, they’re dependable work partners, helping create safer workplaces and better products, much faster than ever.

Why Robot Is Important in Everyday Life

Robots are everywhere now, and not just in big factories or labs. The past few years have shown us that having robots around at home can really change daily routines, making life just a bit simpler and sometimes a lot more independent. People have mixed feelings about it—some are excited, others are a little wary—but it’s getting hard to ignore all the ways these machines are popping up in regular households.

Boosting Convenience Through Smart Home Devices

If you’ve ever watched a smart vacuum zip around the living room or called out to a voice assistant to remind you of a meeting, you’ve already witnessed how robots save brain space and effort. Smart home robots are all about making simple tasks less of a hassle.

Some common examples include:

- Robot vacuum cleaners that map your house and pick up pet hair before you even notice it building up.

- Smart kitchen aids that can stir your soup, monitor oven temps, or even prep simple meals.

- Voice-enabled hubs that let you dim the lights, adjust the thermostat, or lock the doors without lifting a finger.

And here’s the kicker—this stuff works in the background, pretty quietly, and it just lets you focus on, well, living.

Table: Popular Smart Home Robots (2025)

| Type | Task | Example Brands |

|---|---|---|

| Vacuum | Floor cleaning | iRobot, Eufy, Roborock |

| Mower | Lawn care | Worx, Husqvarna |

| Kitchen Assistant | Cooking, meal prep | Moley, Suvie |

| Security Robot | Monitoring, patrolling | Ring, Anki |

Empowering Independence for Seniors and Individuals with Disabilities

One of the biggest game changers? Robots that help people live on their own terms. This is especially true for seniors and those with mobility issues. There’s nothing quite like being able to stay in your own home safely, even if everyday jobs get a little harder as you age or if you have a disability.

Here’s what’s making a difference:

- Robotic exoskeletons that help people walk after injury or surgery.

- Personal care robots that fetch items, remind you to take medication, or monitor vital signs.

- Smart wheelchairs with sensors to prevent dangerous bumps or falls.

The tech isn’t perfect, but for a growing number of people, it’s making independent living possible.

Time Savings and Improved Lifestyle Quality

Let’s face it—most of us feel like we’re always short on time. Between work, family, and chores, downtime is tough to find. By taking care of repetitive, boring tasks, household robots start to give a little of that precious time back.

Here are three ways robots boost daily life quality:

- Less time spent cleaning or mowing means more time for hobbies or family.

- Automated reminders reduce stress about forgetting bills or appointments.

- Home robots can even help manage meals, reducing the mental load of daily planning.

All said, in 2025, many folks are no longer asking “should I get a home robot?” but rather, “which one actually fits my life?” They don’t do everything, but for many people, these machines are taking on the stuff we’d all rather skip.

Transforming Healthcare and Biotech with Robotics

Robots aren’t just operating in warehouses and cars anymore—they’re changing hospitals and labs in ways that seemed out of reach a few years ago. In 2025, robotic systems are central to almost every area of healthcare, making care safer and freeing up human workers for tasks that need a personal touch. Here’s a closer look:

Robotic-Assisted Surgeries and Patient Care

If you know anyone who’s had surgery lately, there’s a good chance robotics played a part. These machines can hold instruments steady, give surgeons a closer look, or even move with precision a human hand just can’t match. Here’s what makes robotic-assisted procedures a big deal:

- Smaller cuts and faster healing times — patients spend less time in the hospital.

- Surgeons can see detailed, magnified images, making tough or delicate operations easier.

- Some patients who were high-risk for regular surgery can now be treated safely.

And it’s not just surgery. Robots deliver medicine, disinfect rooms, and wheel food to patients all day long—quietly keeping hospitals running.

Accelerating Drug Discovery and Laboratory Automation

Drug development used to take years, with scientists testing thousands of compounds by hand. In 2025, robots can quickly shake, mix, and measure samples, moving through huge batches in a fraction of the time.

Take a look at how robotics is speeding up discovery:

| Process | Manual (Days) | Robotic (Hours) |

|---|---|---|

| Compound screening | 10 | 12 |

| Sample preparation | 8 | 1.5 |

| Data analysis | 6 | 1 |

Lab robots don’t get tired, so results are less likely to be affected by mistakes or oversight. That means more accurate tests and safer drugs for everyone.

Ensuring Consistency and Accuracy in Medical Procedures

Sometimes, it’s the smallest things that matter—like making sure a medicine dose is correct every time. Robots are naturally good at this, which helps reduce problems that come from human error. Perfection is tough for people, but robots are designed to repeat tiny steps again and again with the same result. They also log actions and share data with doctors and nurses so everyone stays in the loop.

Here are just a few routine jobs robots handle well in hospitals:

- Preparing IVs and injections to exact specifications

- Sorting and labeling medication packages

- Monitoring vital signs with zero breaks or distractions

Of course, even as robots become more common, they don’t replace the need for human caregivers. Instead, they fill in support roles, making tough days a little easier for staff and safer for patients. With more robots rolling out every year, from human-like assistants to smart touch-free devices, the healthcare and biotech world in 2025 feels very different than it did just a decade ago.

Driving Sustainable Solutions and Environmental Impact

Robots have become a surprising ally in tackling some of the biggest environmental problems we’re dealing with in 2025. As pressure grows to reduce waste and protect resources, automation isn’t just changing the way businesses work; it’s also helping us take care of the planet in ways that used to be impossible or far too expensive. Here’s a closer look at how:

Robots in Recycling and Resource Optimization

Trying to sort recycling manually just isn’t realistic anymore, not with the volume cities deal with. Robots powered by machine vision can pick out recyclables from trash at lightning speed.

- Sorts materials more quickly than any human crew

- Reduces contamination, leading to higher-quality recycled products

- Recovers valuable resources, cutting raw material demand

Here’s a simple comparison of typical human and robotic sorting rates:

| Method | Items Sorted/Hour | Estimated Accuracy |

|---|---|---|

| Human Crew | 800 | 80% |

| Robotic Arm | 2,500 | 95% |

Supporting Agricultural Efficiency and Sustainability

Farmers face both weather changes and increasing demand for food. Robots in tractors or drones help solve production and sustainability problems with precision tasks, like:

- Automated planting — seeds get spaced perfectly, so nothing’s wasted.

- Targeted pesticide application

- Soil and crop analysis to catch problems before harvest is at risk

As a result, farmers use less water, cut chemical runoff, and yield more from every field. It adds up to healthier farms and better food security.

Reducing Industrial Waste and Emissions

Factories once produced tons of scrap because mistakes went unnoticed until it was too late. Now, robots run constant checks and adjust machinery on the fly, so less goes to landfill. Here’s what industrial robots help accomplish:

- Cut flawed product rates dramatically

- Lowered energy use by keeping lines running efficiently

- Identify leaks or emissions no human eye can spot

This shift isn’t just saving companies money—it’s shrinking their environmental footprints in a way regulations alone never could.

In short, the way robots are being used in 2025 changes how we deal with the planet’s finite resources. The tech might not be perfect yet, but it’s giving us more sustainable options than we ever had before.

Addressing Workforce Challenges and Economic Growth

Robotics has forced everyone to rethink how we work. Factories, offices, and even farms are solving problems that have bugged them for years. What’s wild is, it’s not just about robots replacing jobs, but actually filling the gap where jobs can’t be filled and creating opportunities where nobody expected. Let’s break down how robots are shaking up the workforce and the whole economy in 2025.

Filling Labor Gaps in Critical Sectors

You don’t need to go far to see labor shortages right now, whether it’s hospitals, warehouses, or construction sites. A lot of jobs just aren’t getting enough takers—some are too risky, others are too repetitive or physically hard. Robots step in exactly there, doing the heavy lifting:

- Robots can handle dangerous tasks in mining, manufacturing, and even emergency response.

- Automation keeps supply chains running even when there aren’t enough workers available.

- Healthcare robots take care of simple monitoring and patient transport, freeing up overworked staff.

Here’s a simple table breaking down where the biggest labor gaps exist and how robotics is helping:

| Sector | Labor Shortage 2025 | Robotics Solution |

|---|---|---|

| Healthcare | 320,000* | Patient care, logistics |

| Agriculture | 210,000* | Crop picking, monitoring |

| Manufacturing | 450,000* | Assembly, inspection |

*Numbers are rough global estimates.

Enabling New Job Creation in Robotics and Technology

The myth that robots only steal jobs doesn’t really fit what’s actually happening today. If anything, robotics is opening doors for:

- Technicians and engineers who design, test, and maintain robots.

- Software developers writing control code, apps, and AI routines.

- Support and training staff who teach others how to work with new tech.

Plus, whole new roles are being invented as smaller companies figure out their own ways to use robots. Sure, some old jobs are going away, but a lot of people are moving into better-paying work that didn’t even exist a few years ago.

Shaping the Future of Work with Human-Robot Collaboration

It’s not all about machines working alone. What’s happening more and more is robots and people teaming up:

- Collaborative robots (cobots) work right beside humans on production lines.

- Robots handle the boring or unsafe parts, while humans do quality checks and solve tricky problems.

- Workers don’t need to be engineers to use these robots; new systems are built to be easy for everyday people to use and program.

Some of the main benefits people are seeing with these human-robot teams:

- Higher productivity without burning out staff.

- Fewer injuries and less repetitive strain.

- Opportunity for workers to move into roles that need decision-making, creativity, and people-skills.

Bottom line: Robots are taking care of tough problems with the workforce, but they’re also making room for people to do the jobs only humans can do. That’s why robotics is such a big deal for the economy and the future of work in 2025.

Building Public Trust and Overcoming Adoption Hurdles

Convincing people to trust robots is honestly one of the trickiest parts of rolling them out everywhere. It’s not just about having the right tech—it’s about making people feel safe and like these new gadgets actually make life better. Here’s how the industry is tackling it in 2025:

Demonstrating Real-World Benefits to Society

People want to see with their own eyes how robots actually make a difference in daily life. If a robot can’t make mornings easier, keep the house safer, or let someone with mobility issues get around better, trust just doesn’t grow. The "show, don’t tell" attitude is alive and well—you can talk all you want, but results speak louder.

Recent surveys show that about 39% of developers believe people need to see direct benefits, like:

- Robots helping with tough or repetitive chores (think laundry or vacuuming)

- Making everyday living safer or more comfortable (fall detection for seniors, anyone?)

- Taking care of boring jobs so people can do more of what they love

If your neighbor’s robot cooks them dinner or senses a gas leak, it’s way easier to imagine yourself trusting one too.

Navigating Safety, Ethics, and Privacy Concerns

This is where the headaches start. Safety is everyone’s biggest worry, especially in places like homes with kids or in hospitals. And there’s also the fear of robots being misused on purpose or going haywire due to glitches.

Here’s what’s on most folks’ minds:

- Who’s responsible if a robot messes up and someone gets hurt? (The person controlling it? The company? The techs?)

- Can a hacker take control of my home robot?

- Will these things take everyone’s jobs?

Some new standards are starting to help, like UL 3300, made just for certifying home and service robots. But rules are still all over the place, and it’s keeping a lot of robots from hitting the market as fast as possible.

Here’s a quick look at survey data from 2025:

| Concern | % of Respondents Worried |

|---|---|

| Accountability & Liability | 68% |

| Job Displacement | 60% |

| Home Safety & Reliability | 63% |

| Misuse for Malicious Purposes | 57% |

Establishing Industry Standards and Certification

Robotics is moving fast, but laws and safety rules are still playing catch-up. For anyone designing robots, keeping up with changing standards is its own challenge. Certification isn’t a nice-to-have—it’s a must if robots are going to live or work side-by-side with people.

Current pushes include:

- Updating international safety standards (like ISO 10218) as robots become smarter and more independent

- Getting third-party safety certifications for anything meant for home use

- Building fail-safes and backup plans into robots so they can be shut down or remote-controlled if something goes wrong

Ultimately, adoption comes down to people seeing robots as reliable, helpful, and safe. The more industries, engineers, and lawmakers work together, the more robots will move from being gadgets for techies to being trusted parts of daily life.

Conclusion

Looking at where we are in 2025, it’s kind of wild to see how much robots have changed both work and daily life. What started as simple machines on factory lines is now everywhere—helping doctors in surgery, delivering packages, and even cleaning up around the house. Sure, there are still some bumps in the road, like figuring out costs and making sure people feel safe with robots around. But the benefits are hard to ignore. Robots save us time, help keep people safe, and even open up new jobs we couldn’t have imagined a decade ago. As these machines get smarter and more common, it’s clear they’re not just a passing trend. They’re shaping the way we live and work, and honestly, it’s exciting to think about what’s next. If you’re curious or maybe a little nervous about robots, you’re definitely not alone. But one thing’s for sure—robots are here to stay, and they’re making a real difference.