Aerospace Labs Spearheading Artificial Intelligence and Data Science

Aerospace labs have become the front-line testing grounds for AI and data science experiments. It seems like every month, there’s a new system in some lab that’s changing how we approach spacecraft, aircraft, and even satellite missions. These places don’t just build rockets. They build the brains behind them.

AI-Driven Predictive Maintenance Systems

Predictive maintenance has gone from science fiction to something you expect on your project checklist. Engineers use AI to examine mountains of sensor data, and the results make a big difference. Problems get spotted before they cause trouble, and there’s less downtime. Unscheduled fixes—real budget eaters—are way down. For example, using AI, the industry has cut these events by about 30%. What does that actually mean?

| Maintenance Metric | Before AI | After AI (2025) |

|---|---|---|

| Unscheduled Events/Year | 100 | 70 |

| Average Downtime (hrs) | 12 | 6 |

| Maintenance Cost (%) | 100% | 75% |

Here’s how these systems work in labs and out in the field:

- Constantly gather data from engines, avionics, and climate controls

- Use machine learning to notice odd patterns or out-of-range signals

- Predict exactly which part needs attention and when

Machine Learning for Rapid Design and Prototyping

Back in the day, it would take months—or even longer—just to test new ideas. Machine learning has flipped that. Now, labs run thousands of virtual experiments in less time than it takes to pick up a sandwich. Some key shifts:

- Algorithms propose dozens of tweaks to models within hours

- Engineers focus energy on the most promising options, boosting productivity

- Prototypes get built fast—labs report time cut by more than half in some cases

Instead of endless test cycles, the machine picks out what matters. Teams can try wild ideas and get feedback before lunchtime.

Data Science Applications Enhancing Space Operations

Data science isn’t just about crunching numbers—it’s reshaping mission control. Aerospace labs rely on data-driven methods in nearly every area:

- Sharper route planning for spacecraft and satellites

- Live analysis of environmental risks, like solar storms or orbital debris

- Spotting improvement opportunities for fuel use and safety

What’s wild is seeing lab-built algorithms now running during real launches. One recent mission used live AI planning to dodge orbital debris. Instead of waiting for ground control’s call, the spacecraft got a new path in seconds.

In short: Aerospace labs don’t just mess around with cool science projects—these teams are the ones making space missions safer, cheaper, and way more reliable.

Sustainable Solutions Forged in Aerospace Labs

Aerospace labs have become testing grounds for greener, more efficient space technologies. Science fiction dreams like reusable rockets and eco-friendly fuels? Those are getting closer to reality inside these labs. The work is full of trial, error, and sometimes, real surprises. Here’s a peek at three major areas where sustainability is now front and center:

Development of Next-Generation Propulsion Technologies

There’s a major push to get rid of waste in rocket launches. Modern labs are experimenting with propulsion systems that create fewer emissions and use less toxic chemicals. Here are some of the projects making waves:

- Electric propulsion for satellites: Uses ionized gases, reducing propellant waste and extending mission lifetimes.

- Methane-fueled rockets: Easier to produce off-Earth (think Mars), lower carbon output compared to old-school fuels.

- Full reusability: Rockets designed to return safely instead of burning up or crashing after one launch.

The real headache? Balancing efficiency and cost. Some of these next-gen engines are experimental and so expensive that only big agencies or funded startups can play.

Advancements in Sustainable Aviation Fuels and Materials

Replacing standard jet fuel isn’t a small job. New sustainable aviation fuels (SAFs) can cut CO₂ by as much as 80% over their full lifecycle. These blends come from sources like used cooking oil, agricultural waste, or algae. Labs have also been toughening up carbon fiber composites, making lighter airframes and less drag.

Quick Comparison Table: Conventional vs. Sustainable Solutions

| Metric | Conventional Jet Fuel | Sustainable Fuels (SAF) |

|---|---|---|

| CO₂ Emissions (lifecycle) | Baseline | Down 60-80% |

| Source | Fossil | Bio/renewable |

| Airframe Weight | 100% | 75-80% (with composites) |

| Recyclability | Low | Improving fast |

Unlike old jet engines, these new approaches may need design tweaks—but the savings add up over time. Airlines and space programs are all over this, since the rules are tightening year after year.

Reducing Space Debris Through Lab-Inspired Innovation

The pile-up of junk in orbit is finally getting serious attention. Labs are working on smart ways to handle the mess:

- Satellites designed to deorbit themselves safely.

- Materials that break up faster in the atmosphere.

- Robotic arms (sometimes the size of mop buckets) to grab and drag space junk down.

It sounds simple but actually needs a lot of testing both on Earth and in space. Labs often set up simulations (with weird setups of springs, cables, and dummy satellites) to see what works before going sky-high with it.

Space is open for business, but the way forward is definitely green. Aerospace labs are scrambling every day, running tests, pulling all-nighters, trying to get us there without trashing the solar system on the way.

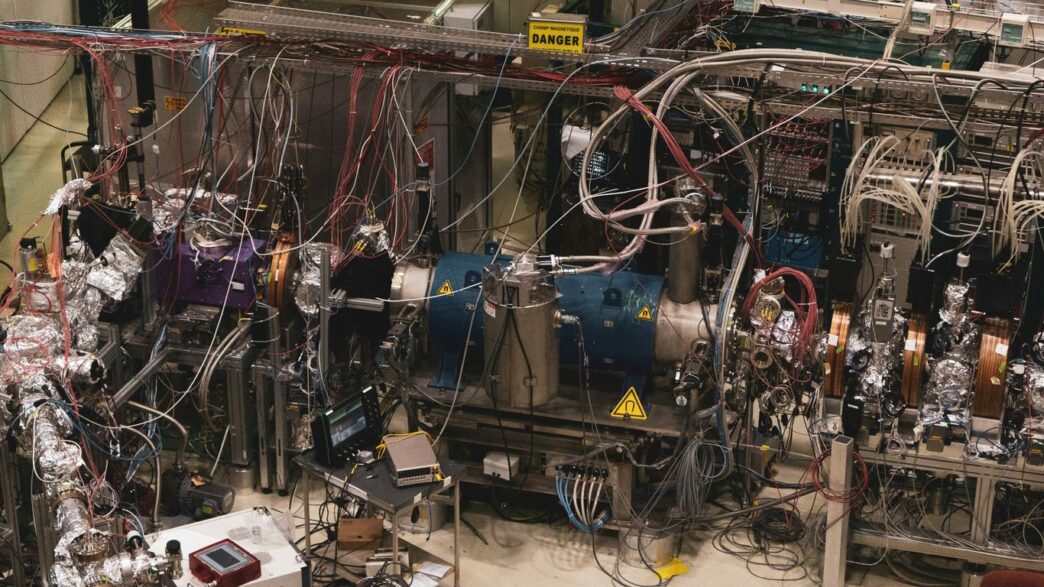

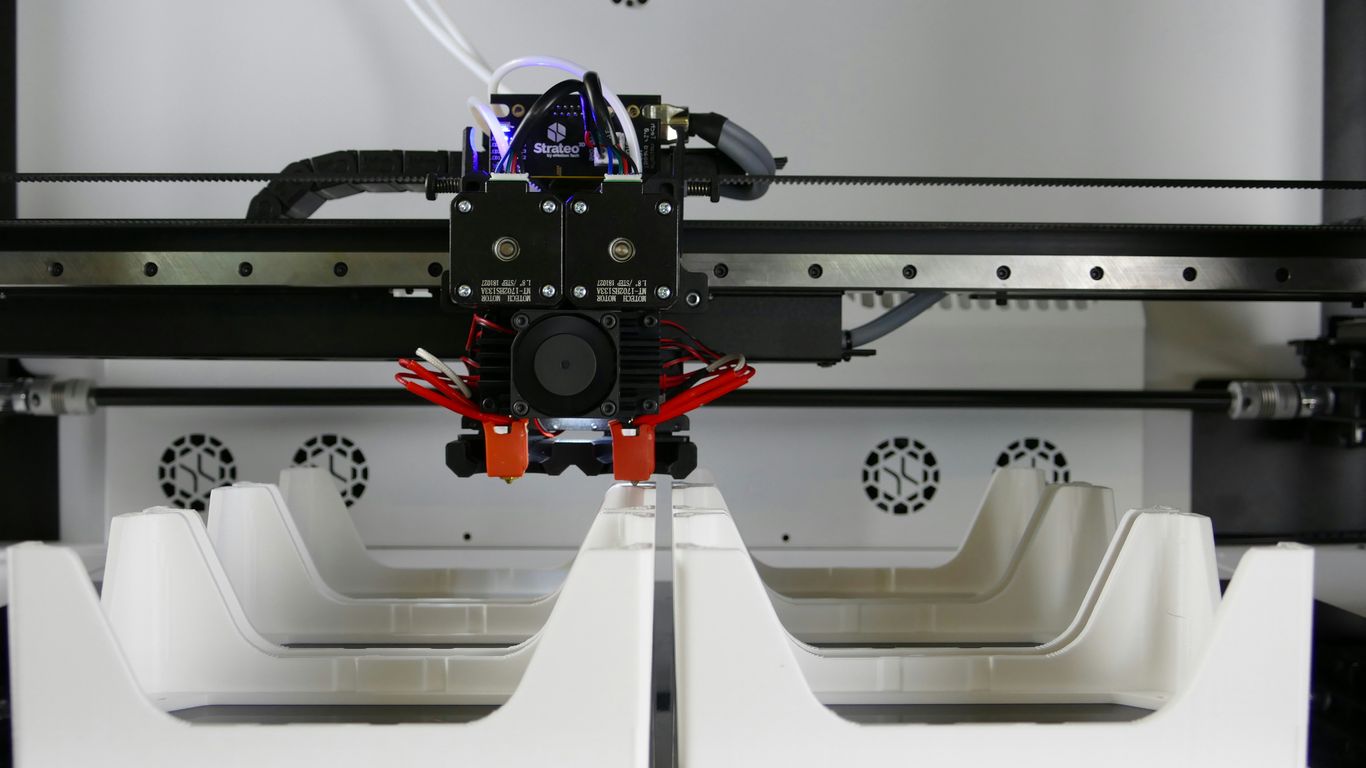

Additive Manufacturing and Advanced Materials in Aerospace Labs

Aerospace labs got serious about 3D printing and fancy new materials, and it’s made a real difference in how we build things for space. No more waiting around for months while a part is carved out—now you can print a whole satellite part in days, sometimes hours. The combo of clever design and smarter materials means everything is lighter, faster to make, and hopefully, lasts longer.

Transforming Spacecraft with 3D Printing

These days, it feels like every company is bragging about their 3D-printed parts. But for good reason. 3D printing can combine twenty separate pieces into one solid part, chopping weight and cutting the number of things that could go wrong in space. It’s not just for prototyping either. Now, we have flight-ready hardware built this way—think engine nozzles, brackets, sensor housings, even full satellite frames.

A few key perks from 3D printing in aerospace:

- Less material waste, since you only use what you need

- Custom shapes that weren’t possible (or affordable) before

- Repairs or new parts printed on-demand, maybe even in orbit someday

Here’s a look at what the market is doing:

| Year | Aerospace Additive Manufacturing Market Value (USD B) |

|---|---|

| 2024 | 7.5 |

| 2025 | 8.6 (est.) |

| 2029 | 9.87 (proj.) |

New Composite Materials for Lightweight Satellites

Everyone working in labs is now obsessed with making things lighter. Why? Because weight in space is expensive. So, they’re using more carbon fiber and other composites—Boeing and Airbus both make their newest jets over 50% out of composites. Even satellites are seeing this shift: whole frames are built using these materials, meaning it’s cheaper to launch, not to mention better for the planet since you need less fuel.

Some benefits of advanced composites:

- Strong-to-weight ratio beats aluminum by a mile

- Resistance to temperature swings, perfect for space

- Less fuel = less carbon emissions over a satellite or airplane’s life

Smart Materials Enabling Predictive Maintenance

You’ve probably heard about smart materials—these are kind of like the "fitbits" for satellites and planes. They’re built to sense damage, wear, or any kind of trouble. They send signals back so engineers on Earth can keep an eye on things without waiting for a failure. Predictive maintenance isn’t just a buzzword; it means catching problems early and fixing them before something (literally) breaks apart in orbit.

How are labs using these smart materials?

- Embedding sensors to monitor structural health in real-time

- Using "self-healing" coatings that repair tiny cracks or nicks automatically

- Feeding monitoring data into AI systems for faster alerts and fixes

All of this means fewer disasters, fewer emergency repairs, and hopefully less stuff turning into space junk. The future’s looking pretty clever—thanks to a mix of new tech and old-fashioned lab work.

Cybersecurity and Digital Resilience in the Space Sector

With the explosion of satellites, unmanned vehicles, and connected ground assets, the space sector has become a prime target for cyber threats. Attacks have jumped by 600% in just one year, shaking up how aerospace labs approach cybersecurity. New tools and strategies—like zero trust frameworks and quantum-safe encryption—aren’t just buzzwords; they’re everyday necessities.

Zero Trust Frameworks for Satellite Networks

Trust used to be the default, but not anymore. Zero trust in the aerospace world means that every attempt to access a system—by a user, device, or third-party tool—is double-checked. Some key elements include:

- Every device or user must be verified, no matter their location

- Continuous monitoring for unauthorized changes or odd behavior

- Limited access according to job role and credentials

These frameworks keep sensitive mission data safer as satellites constantly exchange information across a mesh of networks.

AI-Powered Threat Detection and Response

Manual threat hunting? Not possible at this scale. Aerospace labs now use AI tools trained to spot the smallest anomalies. Here are a few things AI does better and faster than humans:

- Analyzes log files across hundreds of satellites in real time

- Flags irregular traffic that might signal malware or a breach

- Generates automatic system security reports for regulators

Take a look at what’s changed:

| Method | Time Required (2020) | Time Required (2025) |

|---|---|---|

| Manual vulnerability scan | Weeks to months | Minutes |

| Automated AI detection | Hours | Seconds |

| Incident response & reporting | Days | Automated, real-time |

Labs also now run monthly cyberattack drills—just like fire drills—so teams know exactly what to do.

Quantum-Safe Encryption for Space Missions

Quantum computers threaten to break today’s strongest encryption. Labs are already adopting new cryptographic methods to stay ahead, including:

- Lattice-based encryption that resists quantum attacks

- Key exchanges using quantum key distribution (QKD) between satellites

- Frequent updates of cryptographic keys mid-mission

Engineers say this is like upgrading a bike lock to a bank vault—future hackers don’t stand a chance, or at least not for a while.

In the end, today’s space cybersecurity is like a moving target: attackers find new gaps, and labs respond just as quickly. Thanks to smart strategies and relentless testing, the sector isn’t just catching up—it’s staying a step ahead.

Immersive Technologies Redefining Aerospace Training and Collaboration

Immersive technologies are shaping the way aerospace professionals learn, practice, and work together—sometimes far apart. These tools blur the line between real and digital, changing what’s possible in training, testing, and engineering.

Virtual and Augmented Reality in Pilot and Astronaut Training

Virtual reality (VR) and augmented reality (AR) are quickly replacing old-school simulators and training rooms. Why?

- VR cuts traditional aerospace training time by up to 75%. Boeing pulled this off when they overhauled training programs for technicians and pilots, saving both time and money.

- US military programs now run their crews through complex scenarios in VR, letting them make mistakes and learn risks—without real-world danger.

- Astronauts use high-res VR headsets to prep for every phase: pre-launch, docking, even emergency landings. It’s so real they can reach for controls and read cockpit dials like they’re on the station.

- AR overlays live flight data on pilot visors, offering real-time feedback and reducing errors.

Key benefits:

- Risk-free practice for tricky situations.

- Faster, more frequent repetition of maneuvers.

- Cost savings by ditching expensive simulators and extra flight hours.

Digital Twins for Mission Simulation and Testing

Building a rocket or spacecraft is expensive and slow. What if you could test dozens of versions without ever leaving a computer?

- Digital twins are detailed digital copies of real equipment, letting teams run every possible scenario before launch.

- Bell’s helicopter group cut months—sometimes years—off timelines by using virtual models for design, crash testing, and troubleshooting.

- XR platforms mean multiple teams can work on the same virtual satellite at once, tweaking parts, planning launches, and fixing problems before they happen.

Here’s a look at the impact in real numbers:

| Project Type | Traditional Testing Time | Digital Twin Testing |

|---|---|---|

| Avionics Simulation | 8 weeks | 2 weeks |

| Full Mission Rehearsal | 3 months | 4 weeks |

| Design Review | 1 month | 3 days |

Remote Engineering and Maintenance Using Immersive Tools

Aerospace labs are going global with remote work—using immersive tech to close the distance. With full 3D graphics, teams can see and interact with parts as if they’re in the lab, even across continents. This is a game-changer for both everyday maintenance and complex repairs.

- 3D live technology, once just for stage shows like the Lucent Dossier Experience, is now popping up on engineering floors and in mission control rooms.

- Engineers overlay digital instructions right onto their work through AR glasses—no more missing steps or lost time flipping paper manuals.

- Real-time sharing means a specialist can guide a field team, pointing out exactly where to make a fix—without ever hopping on a plane.

A few ways labs and teams get things done faster:

- Virtual walkthroughs let everyone preview missions and spot issues before launch.

- Expert knowledge is available instantly, anywhere in the world.

- Less downtime waiting for travel or parts, more problems solved on the spot.

These technologies aren’t a distant dream—they’re already making aerospace work safer, cheaper, and a lot more flexible. The era of training in isolation is over, and aerospace labs are leading this charge.

Aerospace Labs Driving Satellite and Advanced Air Mobility Innovation

It’s 2025 and aerospace labs aren’t just busy with traditional rocketry—they’re shaking things up with satellites and new ways to move people through the sky. There’s a real shift happening in how labs work with satellites, autonomous aircraft, and ways to keep us all connected from high in the atmosphere. These changes aren’t just for big government programs, either. Startups and private companies are rolling out inventions that make space more accessible, safer, and actually useful for everyday life.

Miniaturization and Rapid Deployment of Satellite Systems

Launching satellites used to take years and cost a fortune. Now, labs are building and testing tiny satellites that can be launched on short notice—and on a shoestring budget. These new satellites often weigh less than 10 kg and pack way more tech inside than their older, heavier cousins. The point? Quick response times for communication, imaging, or weather tracking. Companies like Muon Space are making low Earth orbit constellations that provide fancy tools for climate and security work.

Table: Traditional vs. Modern Nanosatellite Deployment

| Feature | Traditional Satellite | Modern Nanosatellite |

|---|---|---|

| Development Timeline | 3-5 years | 6-18 months |

| Launch Cost | $150M+ | <$1M |

| Mass | 500+ kg | 1–10 kg |

- Fast deployment means better handling of disasters or unexpected outages.

- You can upgrade tech more often, which keeps things up to date.

- This approach makes satellites work almost like smartphones—upgrades are normal, not rare.

Autonomous Aircraft and eVTOL Testing and Development

Flying vehicles are no longer a thing of science fiction. Aerospace labs are making electric vertical takeoff and landing (eVTOL) aircraft, which might change how we get around cities. They’re working on flight-control systems, extra-safe batteries, and autopilot features. There’s a push for safety and reliability above anything else. Some companies are even working toward flying cars with genuine road-to-air flexibility—like what AeroMobil describes in their commercial flying car plans. Testing focuses on real-world problems: sky congestion, energy use, and making sure flights are just as safe as anything on four wheels.

What labs focus on when building eVTOLs:

- Flight control and autonomy testing

- Battery performance and quick charging

- Reducing noise for city operations

- Pilotless (fully autonomous) vs. piloted flight options

By 2045, it’s estimated there could be over 30,000 eVTOLs moving up to 3 billion passengers per year.

Integrating High-Altitude Platforms for Improved Connectivity

Keeping everyone online—whether in Tokyo, a rural farm, or the Atlantic—depends on new platforms flying above commercial jets but below satellites. High-altitude platforms (HAPS)—think solar drones or balloons—act as cell towers in the sky and are being brought to life by real-world lab experiments. These labs work on power management, flight duration, and how to keep a station floating where it needs to be for weeks or months.

Some quick facts:

- HAPS can provide emergency communication when land networks go down

- They’re cheaper to launch and recover than satellites

- They help fill connectivity gaps, especially in remote areas

Aerospace labs are pushing satellite and mobility innovations that people will notice, not just space industry insiders. Whether it’s a sudden bump in your phone’s coverage in the middle of nowhere or flying over traffic in the city, lab-driven work is making it all possible.

University and Industry Partnerships Fueling Aerospace Lab Breakthroughs

Collaboration between universities and aerospace companies is producing some of the biggest changes in space innovation right now. These partnerships give students a way to step out of the classroom and into labs where big ideas are actually built. Universities provide the research know-how and fresh talent, while industry brings the funding, real-world problems, and the infrastructure to scale up solutions fast. Here’s how these connections are shaping the future of aerospace in 2025:

Collaborative Research with Leading Universities

Joint research projects are at the heart of these partnerships. Aerospace labs are joining forces with top schools to tackle everything from reusable rocket tech to new communication systems. This means:

- New propulsion designs get built and tested using university facilities and brainpower.

- Universities run long-term data collection for things like satellite health and propulsion efficiency.

- Several PhD programs now feature internships where students work directly on active aerospace projects.

Example Table: Current Major Collaborations (2025)

| University | Industry Partner | Focus Area |

|---|---|---|

| Caltech | SpaceTech Dynamics | Advanced Propulsion |

| MIT | NovaSat Industries | Satellite Miniaturization |

| University of Texas | StarLift Aerospace | Smart Materials/Deorbiting |

Mentorship and Hands-On Experience for Emerging Talent

It’s not just about research. Mentorship programs are also key. Industry engineers guide students, many of whom end up working in aerospace right after graduation. It looks like this:

- Seniors and grad students pair up with professional engineers for one-on-one coaching.

- Summer placements inside corporate labs, where students do real work—think building prototypes or running safety simulations.

- Workshops and hackathons, often co-hosted by companies, give students fast-paced, real-world challenges.

Bridging Academic Insights with Commercial Space Solutions

Many universities push out new ideas, but turning them into working products takes industry know-how. That gap is closing. Aerospace labs now:

- Hold regular pitch events where students and professors present ideas directly to company R&D.

- Help fast-track patents and spin-outs so promising university inventions become real tools or products.

- Give feedback on academic findings from the perspective of what’s actually needed in commercial spacecraft or satellite missions.

So, in 2025, university and industry partnerships aren’t just a bonus—they’re where huge leaps in aerospace technology are actually happening. The blend of curiosity and practical design is setting the stage for the next decade in space exploration.

Conclusion

So, looking at everything going on in aerospace labs right now, it’s clear they’re not just tinkering with rockets and satellites—they’re actually changing how we think about space. These labs are where wild ideas get tested, where students and experts work side by side, and where new tech like AI, 3D printing, and electric propulsion moves from theory to real hardware. Sure, there are still big challenges, like keeping things affordable and making sure we don’t junk up orbit, but the pace of progress is kind of wild. Every year, something that sounded impossible a few years back is suddenly in the news. If you’re curious about what’s next in space, keep an eye on these labs. They’re the ones building the future, one experiment at a time.