You’ve probably seen the term ‘quantum dot display’ popping up more and more, especially with new TVs and monitors. But what exactly is this technology? It’s not just some fancy marketing buzzword; quantum dots are actually tiny particles that have some pretty cool properties when it comes to light. We’re going to break down what makes them special, how they’re used now, and what the future might hold for screens that use them. Think brighter colors, better efficiency, and maybe even screens on surfaces you wouldn’t expect.

Key Takeaways

- Quantum dots are tiny semiconductor particles that emit specific colors of light when energized, with different sizes producing different colors.

- Current QLED TVs use quantum dots to improve color and brightness by converting blue LED light into red and green.

- Newer QD-OLED technology combines quantum dots with OLED panels for enhanced contrast and color.

- The next big step is direct-view, electroluminescent quantum dot displays, which use electricity directly to make the dots emit light, potentially leading to thinner, more efficient, and cheaper screens.

- This advanced quantum dot display technology could enable screens on almost any surface, from car windshields to eyeglasses, revolutionizing how we interact with displays.

Understanding Quantum Dot Display Technology

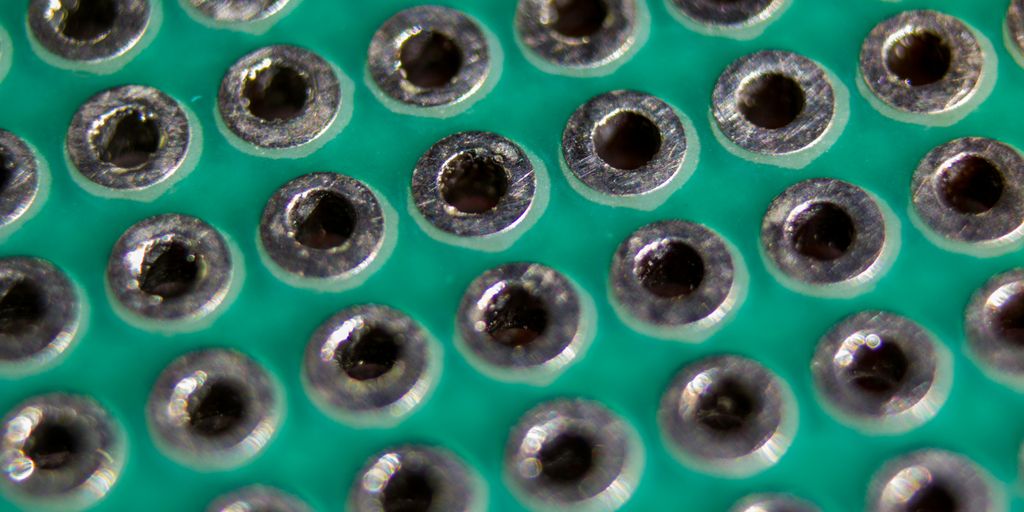

So, what exactly are these quantum dots we keep hearing about in display tech? Think of them as tiny, tiny semiconductor crystals, like, nanometer-sized. They’re so small that their color output changes based on their size. It’s pretty wild. The magic happens when these little guys get hit with energy, causing them to glow. Different sizes mean different colors – smaller dots give off bluer light, and bigger ones emit redder light. This size-dependent light emission is the core of how quantum dot displays work.

The Science Behind Quantum Dots

At their heart, quantum dots are semiconductor nanocrystals. When they absorb energy, like from a light source or an electrical current, they release that energy as light. The color of the light emitted is directly related to the size of the quantum dot. Smaller dots emit shorter wavelengths (bluer light), while larger dots emit longer wavelengths (redder light). This precise control over color based on size is what makes them so special for displays. It’s a bit like having a paint box where you can control the exact shade of every color just by changing the size of your brushstroke, but on a microscopic level.

How Quantum Dots Emit Light

Quantum dots emit light through a process called photoluminescence or electroluminescence. In photoluminescent systems, like many current QLED TVs, quantum dots are excited by an external light source, usually blue LEDs. This blue light hits the quantum dots, which then re-emit light at specific red and green wavelengths. These colors, along with the original blue light, combine to create the full spectrum of colors you see on screen. It’s a way to convert one color of light into purer, more specific colors. Think of it like a color filter, but one that actively generates the color itself. This is a big step up from older technologies that relied on less efficient color filters. You can see some early examples of this technology in action at tech shows, like the ones showcasing 3D Live technology.

Evolution from Photoluminescent to Electroluminescent

Initially, quantum dots in displays were photoluminescent, meaning they needed a separate light source to get them glowing. This is how they were integrated into traditional LCD panels to boost color and brightness. More recently, though, the technology has evolved towards electroluminescence. This means the quantum dots themselves emit light when an electric current is applied directly to them, much like OLEDs. This direct-view, electroluminescent approach is a game-changer. It promises displays that are not only brighter and more colorful but also potentially thinner and more energy-efficient because they don’t need that separate backlight layer. This shift is paving the way for entirely new display structures.

Quantum Dots in Today’s Displays

So, where are these amazing quantum dots showing up in our tech right now? Well, they’ve become a pretty big deal in the TV world, especially with QLED sets. You know, the "Q" in QLED actually stands for quantum. These tiny particles are used to make the colors on your screen pop and the picture brighter, especially when you’re watching something with high dynamic range (HDR). It’s not just in the super high-end models anymore either; you can find them in a lot of mid-range and even some more budget-friendly TVs from brands like Samsung, TCL, and LG.

But it doesn’t stop there. Quantum dots are also making their way into newer display types, like QD-OLED. This is where things get really interesting because it combines the best of both worlds – the deep blacks and vibrant colors of OLED with the color purity and brightness that quantum dots bring. Think of it as getting a super-charged picture. They’re even being explored for use in MicroLED displays, which are known for being incredibly bright and efficient. This could mean even better augmented reality experiences or sharper heads-up displays in cars.

Here’s a quick look at how they’re integrated:

- QLED TVs: Quantum dots are typically placed in a film layer or directly onto a diffuser plate. When light from the LED backlight hits them, they emit pure red and green light, which then passes through color filters to create the final image. This process significantly improves color accuracy and brightness compared to traditional LCDs.

- QD-OLED Technology: In these displays, quantum dots are used as color converters. A blue OLED layer emits light, which then passes through red and green quantum dot color converters. This method allows for very precise color control and avoids the color crosstalk issues sometimes seen in other technologies.

- MicroLED Applications: For MicroLEDs, quantum dots can be used to convert the blue or UV light emitted by the MicroLEDs into specific red and green wavelengths. This helps create full-color displays with exceptional brightness and energy efficiency, making them ideal for demanding applications like smart glasses.

It’s pretty wild to think how these microscopic particles are changing the way we see our favorite shows and games.

The Future of Quantum Dot Displays

So, we’ve talked about how quantum dots are already in our TVs and making them look pretty awesome. But what’s next? Well, the real game-changer is when quantum dots can actually make their own light, not just reflect or change light from something else. This is called direct-view electroluminescent quantum dots, and it’s kind of a big deal.

Direct-View Electroluminescent Quantum Dots

Think about it: instead of needing a separate backlight like in LCDs, or relying on organic materials like OLEDs, these quantum dots would light up all by themselves when you send electricity to them. This means screens could get even thinner, use less power, and potentially have even better colors and contrast. It’s like having tiny, super-efficient light bulbs for every single pixel. This technology promises a simpler display structure that could be printed onto almost any surface. Imagine phones, tablets, or even flexible displays that are incredibly bright and vibrant, all while sipping power. It’s still early days, with prototypes being shown off, but the goal is to get this into our hands within the next few years. It’s a big step from where we started with quantum dots.

Potential for Thinner and More Efficient Screens

Because electroluminescent quantum dots create their own light, they don’t need all the layers that traditional displays require. This means we could see devices that are unbelievably thin, maybe even as thin as a piece of paper. Plus, since they’re so efficient at converting electricity into light, battery life on our gadgets could get a serious boost. We’re talking about phones that last days, not hours, or smartwatches that you barely ever need to charge. It’s a pretty exciting prospect for portable electronics.

Scalability Across Devices and Surfaces

One of the most exciting parts about this next generation of quantum dot displays is how versatile they could be. Because the technology is moving towards being printable, it opens up possibilities beyond just your phone or TV. We could see displays integrated into all sorts of everyday objects and surfaces. Think about:

- Smart windows: Imagine your car’s windshield or even your home windows displaying information or acting as a transparent screen.

- Wearable tech: Flexible QD displays could be woven into clothing or integrated into accessories.

- Interactive surfaces: Any flat or curved surface could potentially become a display, from furniture to building facades.

This broad applicability means quantum dots could pop up in places we haven’t even thought of yet, changing how we interact with information and our environment. The global quantum dots market is already growing, and this next wave of technology is expected to drive even more adoption [cd3d].

Manufacturing and Production Advantages

When we talk about making these fancy quantum dot displays, it turns out there are some pretty neat advantages that could make them easier and cheaper to produce down the line. Think about it – simpler designs usually mean fewer headaches during assembly, right?

Simplified Display Structures

One of the big wins with quantum dot tech, especially as it evolves, is how it can simplify the actual construction of a display. Older methods, like traditional LCDs, often involve a lot of layers. You’ve got your backlight, then diffusers, color filters, and then the liquid crystal layer itself. Quantum dots can sometimes cut out a few of these steps. For instance, the second-generation QD displays skip the color filter entirely. Instead of a filter trying to block out light to create colors, they use blue LEDs to excite red and green quantum dots. This not only makes the display brighter but also cuts down on manufacturing complexity. It’s like removing unnecessary parts from a machine to make it run smoother and faster. This simplification is key to making displays more efficient and potentially less expensive to build. It’s a big deal when you consider how many screens we use every day, from phones to TVs. The goal is to get to a point where we can make these advanced displays without needing super complex, expensive factories. It’s a bit like how companies are looking into making computer chips using new methods that don’t require the same massive investments as older techniques, potentially speeding up innovation in areas like photonic devices [a9eb].

Potential for Lower Production Costs

Following on from simpler structures, the potential for lower production costs is a really attractive aspect of quantum dot displays. Because the manufacturing process can be streamlined, it opens the door to using less capital-intensive methods. For example, the third-generation displays, where quantum dots form the light-emitting layer and are excited by electricity, could potentially be made using printing or photolithographic techniques. These methods are generally less expensive than the vacuum deposition equipment needed for technologies like OLED. If you can print the display components instead of using complex machinery, you naturally bring down the cost of each unit. This could make high-quality displays much more accessible to a wider range of consumers and for more applications. It’s not just about making TVs cheaper, either; it could mean more affordable smart glasses, better automotive displays, and even integration into everyday surfaces.

Printable Quantum Dot Displays

And speaking of printing, that’s where things get really interesting for mass production. The idea of printable quantum dot displays is a game-changer. Imagine being able to print display layers like you might print a poster or a photograph. This approach could drastically reduce the cost and complexity of manufacturing. Instead of relying on highly specialized, expensive factories, you could potentially use roll-to-roll printing processes, similar to how newspapers or flexible electronics are made. This would not only lower the initial investment needed to set up production but also allow for much greater flexibility in terms of display size and form factor. We could see quantum dots being used in everything from flexible screens that can be rolled up to displays integrated directly into fabrics or windows. This printing capability is what makes the prospect of widespread adoption so exciting, potentially leading to thinner, more efficient screens across a variety of devices and surfaces.

Emerging Applications and Innovations

Quantum dots aren’t just for making your TV look amazing anymore. These tiny semiconductor particles are starting to pop up in some pretty interesting places, pushing the boundaries of what displays and other tech can do. It’s like they’re finding new jobs all over the place.

Augmented Reality and Smart Glasses

Think about augmented reality (AR) glasses that overlay digital information onto the real world. For these to work well, especially in bright sunlight, the displays need to be super bright and have really accurate colors. Quantum dots are a good fit here because they can produce very pure, vibrant colors and are quite efficient. This efficiency is key for battery-powered devices like smart glasses. Imagine seeing navigation arrows directly on the road ahead or having virtual instructions appear as you work on something. It’s still early days, but the potential for quantum dots to make AR displays more practical and visually appealing is huge. Companies are looking at how to integrate these QD technologies into the compact designs needed for wearable tech.

Automotive Heads-Up Displays

Cars are getting smarter, and heads-up displays (HUDs) are becoming more common. These project important information, like speed or navigation, onto the windshield so drivers can keep their eyes on the road. Quantum dots can help make these HUDs brighter and more colorful, even in direct sunlight. This means critical information is always easy to see. Plus, the precise color control means they can display information without being distracting. It’s all about making driving safer and more convenient. The ability to tune the light output is a big plus for automotive applications where visibility is paramount.

Integration into Everyday Surfaces

This is where things get really futuristic. Researchers are exploring ways to embed quantum dots into all sorts of surfaces, not just traditional screens. Imagine wallpaper that can display information, or clothing that changes color. While this is still very much in the research phase, the idea is to create displays that are flexible, transparent, or even integrated directly into building materials. The potential for printable quantum dot displays means we could see custom displays printed on demand for a variety of uses. This could change how we interact with our environment, making information more accessible and integrated into our daily lives in ways we haven’t even thought of yet. It’s a fascinating area to watch as the technology matures and finds its footing beyond the living room TV. You can find more about the broad applications of quantum dots in various fields.

Comparing Quantum Dot Displays to Other Technologies

So, how do these fancy quantum dot displays stack up against the screens we’re used to? It’s a good question, and the answer really depends on what you’re comparing them to.

Quantum Dots vs. OLED: Key Differences

When you look at a QLED TV, it’s not quite the same as an OLED. QLEDs, as they are now, still use a backlight, kind of like traditional LCD TVs. Quantum dots are added to improve the color and brightness coming from that backlight. OLEDs, on the other hand, are different because each tiny pixel makes its own light. This means when a pixel is supposed to be black, it’s truly off, giving you that super deep black and amazing contrast. The big difference is how they create light: QLEDs use a backlight filtered by quantum dots, while OLEDs have self-emissive pixels. Think of it like this: QLEDs are like a really good stained-glass window with a bright light behind it, while OLEDs are like a collection of tiny, individual light bulbs that can turn on and off.

Advantages Over Traditional LCDs

Compared to the standard LCD TVs that have been around forever, quantum dots are a pretty big step up. Traditional LCDs often struggle with color accuracy and brightness. They use a white LED backlight and color filters, which can limit the range of colors you see and make blacks look more like dark gray. Quantum dots, by converting the backlight’s light into very pure red, green, and blue, can produce a much wider color spectrum and brighter images. This means colors pop more, and you get better detail in both bright and dark scenes. It’s like upgrading from a basic crayon set to a professional artist’s palette.

The Role of Quantum Dots in Next-Generation Screens

Looking ahead, quantum dots are set to play an even bigger role. We’re talking about displays where quantum dots themselves emit light when an electric current passes through them – no backlight needed. This is often called direct-view or electroluminescent quantum dot technology. It promises screens that are even thinner, more energy-efficient, and potentially cheaper to make, maybe even using printing techniques. Imagine phones with screens that last longer on a charge or TVs that are incredibly bright and colorful without using much power. This kind of tech could really change how we interact with screens, making them more versatile and integrated into our lives, perhaps even appearing on flexible surfaces.

So, What’s Next for Quantum Dots?

We’ve seen how quantum dots have already changed our TVs, making colors pop and images brighter. But the real excitement is in what’s coming. Imagine screens that are thinner, use less power, and can be put on almost any surface – think car windows or even eyeglasses. While these super-advanced, electricity-powered quantum dot displays are still a few years out from being in every home, the progress is undeniable. Companies are working hard, and it feels like we’re on the edge of seeing these tiny particles do some pretty big things. It’s a good time to keep an eye on this technology; it might just change how we see the world, quite literally.

Frequently Asked Questions

What exactly are quantum dots?

Think of quantum dots as tiny, tiny specks that glow when electricity or light hits them. The cool thing is, you can make them glow in very specific colors, like red, green, or blue, just by changing their size. This makes them super useful for creating vibrant and accurate colors on screens.

How do quantum dots make TV colors better?

In today’s TVs, like QLEDs, quantum dots help make the colors brighter and more lifelike. They work by taking light from the TV’s backlight and changing it into pure red and green light, while the blue light comes directly from the backlight. This combination creates a much wider range of colors than older TV technologies.

What’s the difference between current quantum dot TVs and the future ones?

The really exciting new stuff uses electricity to make the quantum dots glow directly, without needing a separate backlight. This means screens can be much thinner, use less power, and potentially be cheaper to make. Imagine a TV screen as thin as a piece of paper!

Where else could we see quantum dot screens in the future?

Because these new quantum dot screens can be made very simply, even printed onto surfaces, they could be used in lots of new ways. Think about screens on car windshields for navigation, or even built into smart glasses to show information right in front of your eyes.

How are quantum dot displays different from OLED displays?

The main advantage is better color and brightness. Unlike OLED screens, which can sometimes have issues with images being “burned in” over time, quantum dots are made of inorganic materials, so they don’t have that problem. They also promise to be more energy-efficient.

Why might quantum dot displays be cheaper to make?

Making these new types of quantum dot displays could be easier and less expensive because they require fewer layers and simpler manufacturing processes, like printing. This could eventually lead to more affordable, high-quality screens for all sorts of devices.