RAE Energy has been making some moves lately, shifting its focus and selling off parts of its business. It looks like the company is really zeroing in on its nondestructive testing (NDT) capabilities. They recently sold their coatings division to CRTS Global, which seems like a pretty big deal. This move lets RAE Energy put all its energy into improving its NDT services, which is pretty interesting given how important that kind of work is for keeping pipelines and other industrial stuff running smoothly and safely. It’s a clear sign that RAE Energy is getting ready for what’s next in the energy sector.

Key Takeaways

- RAE Energy sold its coatings division to CRTS Global, allowing it to concentrate fully on nondestructive testing (NDT).

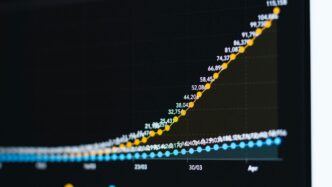

- The company is investing in digital technology and automation to advance its NDT services.

- RAE Energy supports pipeline integrity across upstream, midstream, and downstream operations.

- The acquisition by CRTS Global aims to create a leading provider of comprehensive pipeline field joint coating solutions.

- RAE Energy is positioning itself as a technology-driven NDT provider focused on precision and reliability.

RAE Energy’s Strategic Divestment and Focus on NDT

RAE Energy recently made a significant move, selling off its coatings division to CRTS Global LLC. This isn’t just a minor shuffle; it’s a clear signal that RAE Energy is doubling down on its core strengths in nondestructive testing (NDT) and automated ultrasonic testing (AUT) technologies. The company is now all in on providing advanced NDT solutions that support field operations for its service companies, like Prime Inspections and UT Quality USA and Canada.

This strategic shift comes as the industry itself is changing rapidly. Technology is moving fast, giving us quicker, more accurate inspection tools and access to real-time data. Plus, new codes and standards are tightening up how inspections need to be done and documented. Automation, through robotics and scanners, is also becoming more common, making field work safer and reducing manual effort. RAE Energy is positioning itself to meet these evolving demands, even looking towards using AI for predictive maintenance, moving NDT from a reactive fix to a proactive approach.

- Digital Advancements: Embracing new digital tools for faster, more precise inspections.

- Regulatory Compliance: Adapting to stricter industry standards and documentation requirements.

- Automation Integration: Incorporating robotics and automated systems to improve safety and efficiency.

- Predictive Analytics: Exploring AI to anticipate potential equipment failures before they happen.

By focusing on these areas, RAE Energy aims to be a leader in providing the technology and equipment needed for critical inspections. They support various sectors, from upstream and midstream pipeline operations to downstream industrial applications, helping to ensure safety and efficiency across the board. You can find more details on the equity crowdfunding market and investment trends at HelpTheCrowd analytics.

The company’s commitment is to provide cutting-edge NDT services that are agile, technology-driven, and reliable, especially in tough environments.

Innovations in Non-Destructive Testing

The world of non-destructive testing (NDT) isn’t standing still, and neither is RAE Energy. We’re really leaning into how technology can make inspections better, faster, and more reliable. It’s all about staying ahead of the curve.

Advancing NDT Through Digital Technology

Think about how much things have changed. We’re moving away from just paper records and basic equipment. Now, we’re seeing digital tools that give us real-time data right from the field. This means quicker decisions and a clearer picture of what’s going on with pipelines and other critical assets. It’s a big shift from how things used to be done.

Adapting to Evolving Industry Standards and Automation

Regulations and industry expectations are always getting stricter, and that’s a good thing. New codes mean inspections have to be more thorough and better documented. Plus, automation is a game-changer. We’re seeing more robots and automated scanners that can do the heavy lifting, making the job safer for people and often more precise. It’s about working smarter, not just harder.

Shifting Towards Predictive Maintenance with AI

This is where things get really interesting. Instead of just finding problems after they happen, we’re starting to use artificial intelligence (AI) to predict when something might fail. This moves NDT from being a reactive process to a proactive one. Imagine being able to fix a potential issue before it even causes a shutdown – that’s the goal. It’s about keeping things running smoothly and preventing unexpected downtime.

RAE Energy’s Role in Pipeline Integrity

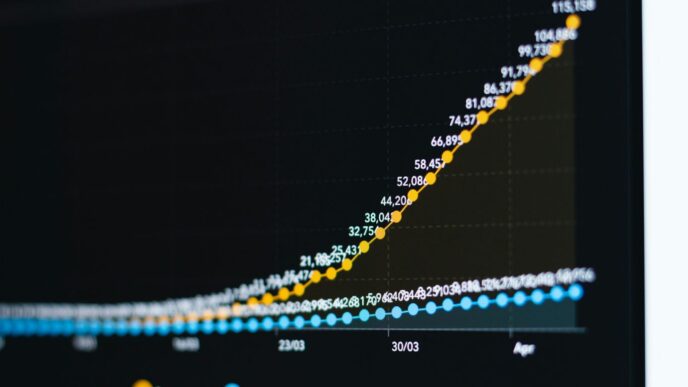

RAE Energy plays a big part in keeping pipelines in good shape, from the very start of oil and gas operations all the way through to the final products. They supply the gear and tech that inspection companies need to do their jobs right.

Supporting Upstream and Midstream Pipeline Operations

For the folks working on getting oil and gas out of the ground (upstream) and moving it through big pipes (midstream), RAE Energy provides the advanced equipment. This helps inspection teams check new construction and keep existing pipelines, like flowlines, gathering lines, and trunk lines, in good working order. They also support the big pipeline contractors in North America with their tools for transmission pipelines and terminals. It’s all about making sure these vital lines are safe and running smoothly.

Providing Technology for Downstream and Industrial Inspections

When it comes to processing and refining (downstream), RAE Energy’s technology is used by NDT service providers to check product and service pipelines. They also support inspections in places like refineries and chemical plants. This means checking things like piping systems, tanks, and other critical equipment. It’s a wide range of work, and RAE Energy’s tech is there to help.

Enhancing Safety and Efficiency in Field Execution

RAE Energy’s focus is on providing the technology that makes inspections safer and more efficient. They work with companies like Prime Inspections and UT Quality, supplying them with the equipment for both regular and digital NDT. This support helps these companies handle some of the biggest pipeline inspection jobs out there. It’s about making sure the work gets done accurately and without issues, even in tough spots. You can see how important this kind of tech is when you look at advancements in areas like mobile technology, where things are constantly changing Padmasree Warrior, CTO of Cisco, highlights key technology trends shaping a bright future.

Here’s a quick look at where their tech is used:

- Upstream: Flowlines, gathering pipelines, feeder pipelines, trunk lines.

- Midstream: Transmission pipelines, pipeline terminals.

- Downstream: Product pipelines, service pipelines.

- Industrial: Piping systems, pressure vessels, storage tanks, heat exchangers.

CRTS Global’s Acquisition of RAE Coatings

So, CRTS Global just picked up RAE Energy’s coatings division, which they’re now calling RAE Coatings. This is a pretty big deal for CRTS, as it really beefs up their standing in the whole pipeline coatings scene worldwide. Apparently, after this deal, CRTS is the only company out there that can handle both the inside and outside coating jobs for offshore pipelines. That’s a pretty unique spot to be in.

Enhancing Offshore Field Joint Coating Solutions

CRTS has been doing its thing in pipeline coatings for a long time, over 40 years actually. They’re known for their robotic machines that coat the inside of pipes. But RAE Coatings? They’re the ones who really know their stuff when it comes to the protective coatings on the outside of offshore pipes. They’ve got these special ways of doing things that customers in places like the Gulf of Mexico, the North Sea, and Southeast Asia have relied on. Now, with RAE Coatings on board, CRTS can offer a much wider range of services for pipeline projects, both on land and out at sea. They’re talking about things like IMPP, EMPU, PUF, and some patented rapid coating stuff. It sounds like they’re aiming to be a one-stop shop for pretty much any coating need.

Expanding Global Reach and Service Offerings

This move means CRTS, which is based in Dubai, is now even more of a global player. They already have offices in a bunch of places, but adding RAE Coatings’ operations, especially in key offshore areas, just makes their network stronger. They’re saying this acquisition helps them provide a more complete and efficient way to protect pipelines from corrosion, no matter where the project is. It’s all about giving customers more options and better service across the board. They’ve apparently coated over three million field joints already, which is a lot of pipes!

Synergies in Proprietary Technologies and Workforce

What’s interesting is how they’re talking about combining their technologies. CRTS has its robotic internal coating tech, and RAE Coatings has its specialized external coating methods. By putting them together, they think they can create even better solutions for corrosion resistance. Plus, they’re bringing in RAE Coatings’ experienced team. Bryan Kirchmer, the President at CRTS, mentioned that RAE Coatings’ people and their unique technologies are going to help them serve customers worldwide more effectively. It seems like a smart move to combine forces and offer a more robust package of services, especially for tough offshore environments. You can check out more about CRTS at www.crtsglobal.com.

RAE Coatings’ Legacy in Pipeline Protection

Leadership in Offshore Pipeline Protective Coatings

RAE Coatings really made a name for itself in the offshore world. They were known for putting tough protective layers on pipelines that run under the sea. These aren’t just any pipelines; they’re the ones moving oil and gas from where it’s found to shore, often over many miles and through some seriously rough conditions. Think about the pressure from the water, the strong currents, and the seabed itself – it’s a lot for any piece of equipment to handle.

RAE’s job was to make sure these pipelines could withstand it all. They focused on solutions that would last, fighting off corrosion, which is a big problem in saltwater, and protecting against physical damage. It wasn’t just about slapping on some paint; it was about advanced application techniques to keep these vital lines safe and working for a long time.

Advanced Service Capabilities in Key Offshore Markets

What set RAE Coatings apart was their ability to operate in major offshore hubs, particularly in North America and Southeast Asia. This meant they could get their specialized teams and equipment to where they were needed, whether it was a new project or maintenance on existing infrastructure. They managed the whole process, from getting the right people and gear there, to handling the logistics and making sure everything was stored properly.

They offered a full package, really. This included managing the projects from start to finish, having a pool of skilled workers ready to go, and coordinating all the necessary equipment and supplies. This kind of end-to-end service was pretty important for companies building or maintaining offshore pipelines, as it simplified a very complex part of the operation.

Commitment to Durability and Corrosion Resistance

At its core, RAE Coatings was all about making pipelines last longer and perform better. Their commitment was to provide coatings that offered serious protection. This meant using materials and methods designed to resist the harsh marine environment, which is constantly trying to wear things down.

They were particularly good at applying coatings that could handle:

- Corrosion: The salty water is a major enemy, causing metal to degrade over time.

- Mechanical Damage: Pipelines can get bumped or scraped by anchors, rocks, or even the movement of the seabed.

- Extreme Temperatures: Both the water temperature and the temperature of the fluids inside the pipeline can put stress on the protective layers.

Their focus on durability meant that pipelines they worked on were less likely to have problems down the line, reducing the need for costly repairs and minimizing downtime. It was a practical approach to a very demanding industry.

The Future of RAE Energy’s NDT Services

So, what’s next for RAE Energy’s non-destructive testing side of things? Well, after selling off the coatings part, they’re really doubling down on NDT. Think of them as a tech company that happens to work in inspections. They’re building teams that are quick on their feet and really know their tech.

Agile, Technology-Driven Inspection Teams

RAE Energy is all about making sure their inspection teams are ready for anything. They’re not just sending people out with old gear anymore. It’s more about having smart, adaptable teams that can use the latest digital tools. This means faster inspections and better data, which is a big deal when you’re working on critical infrastructure. They’re basically training their people to be experts with the new wave of inspection tech.

Delivering Solutions for Industrial NDT Service Providers

Their main goal now is to support other companies that do NDT work. They provide the advanced equipment and the digital systems that these service providers need to get the job done right. It’s like they’re the tech backbone for companies like Prime Inspections and UT Quality USA. This setup helps these companies perform some of the biggest pipeline inspection jobs out there, safely and accurately. It’s a partnership approach, really, where RAE Energy provides the tools and the know-how.

Commitment to Precision and Reliability in Challenging Environments

Whether it’s deep underwater for offshore pipelines or out in the field for onshore projects, RAE Energy is focused on making sure their technology works. They’re known for their Automated Ultrasonic Testing (AUT) equipment, especially for those tough subsea jobs. They also support onshore work, from new pipeline construction to integrity checks. The idea is to make inspections more precise and dependable, no matter how tough the conditions get. They’re really pushing the boundaries on what’s possible with inspection technology, aiming for fewer errors and more reliable results every time.

Wrapping Up: RAE Energy’s New Direction

So, RAE Energy has made a big move, selling off its coatings part to CRTS Global. It sounds like a pretty smart play, letting them really focus on what’s next, which is their NDT and AUT tech. They’re putting all their energy into improving how pipelines get checked out, making things safer and more accurate. It’s a big shift, but it seems like they’re getting ready for whatever the future of energy inspections looks like. We’ll have to keep an eye on how this all shakes out for them and their new focus.