Technology

WiMi Developed A Holographic MES Intelligent Production Management System

With the development of the industrial Internet, the promotion of Industry 4.0 and intelligent manufacturing stimulate more and more enterprises to explore visual data analysis of industrial production. The construction of an MES intelligent industrial production management system can enable enterprises to convert a large amount of real-time data into visual information graphics displays, which can better help enterprises to carry out production planning, scheduling, exception analysis, quality control, production management decision-making, and other management activities. WiMi Hologram Cloud, Inc. (NASDAQ: WIMI) provides users with visual solutions for production management, assists enterprises in digital transformation and upgrading, and improves production efficiency and economic benefits.

WiMi Hologram Cloud developed a holographic MES intelligent industrial production management system in the WiMi Holographic Cloud Platform based on customer needs and actual use. The “WIMI Holographic MES Intelligent Production Management System” developed by WiMi Hologram Cloud can integrate two-dimensional digital content with natural three-dimensional scenes through AI recognition technology and holographic projection technology, and display physical equipment, process flow, product process, production data, and other information into 3D settings in real-time, bringing customers a new immersive experience.

WIMI Holographic MES intelligent production management system is developed with a new 3D engine, which can better show the actual scene of the factory; AI identification technology is adopted to automatically identify equipment model, material type, and other information; The 3D modeling and visualization tools are used to realize the visual display of workshop production, and the dynamic interaction and real-time rendering technology of 3D models are used to display the plant operation status and other information; Support multi-dimensional display, including plane, elevation, three-dimensional space, physical product display, and real-time data display.

In terms of human-computer interaction, WIMI holographic MES intelligent production management system provides a variety of human-computer interaction input modes. In terms of interface design, it supports different types of display interfaces, such as 3D display, 3D video, etc., and can realize 3D model display and dynamic demonstration of equipment through AI recognition technology; At the same time, users’ usage habits shall be fully considered in the interaction design, for example, the system can support simultaneous collaborative access by multiple people.

In the aspect of data application, the statistics and analysis of enterprise production data are carried out to help enterprises find problems in the production process promptly and monitor and warn the abnormal situations in the production process to achieve real-time monitoring and odd early warning of various production indicators. Through real-time online data, intelligent analysis, and visual display, WIMI holographic MES intelligent production management system can intuitively see the actual operation status of the factory, the overall process in the current workshop, and the number of operators required at each station. Let enterprise managers comprehensively understand production process parameters, process routes, and other aspects of data performance. Through the visual display, we can understand the actual operation of the factory more intuitively and stereoscopically, provide the basis for scientific decision-making, and improve the advanced management level of the enterprise.

WIMI holographic MES intelligent production management system can analyze the equipment status in real-time through AI identification technology, such as whether it is running, shutdown, overhauling, etc., and provide equipment maintenance plans and time suggestions. The system can automatically calculate the maintenance proposal according to different equipment, such as whether the essential parts have faults, equipment operation status, etc. The system supports the equipment management of the production workshop. The production personnel can view and control each equipment’s regular operation and working status in real-time through the 3D visualization platform. At the same time, detailed information on production equipment, such as model name, quantity, and usage status, can be automatically synchronized to the enterprise intranet. The system can predict and analyze different types of equipment and predict whether the production plan for the next month is consistent with the actual situation according to historical data and market conditions to take measures in time; Further adjust the production plan based on the forecast results.

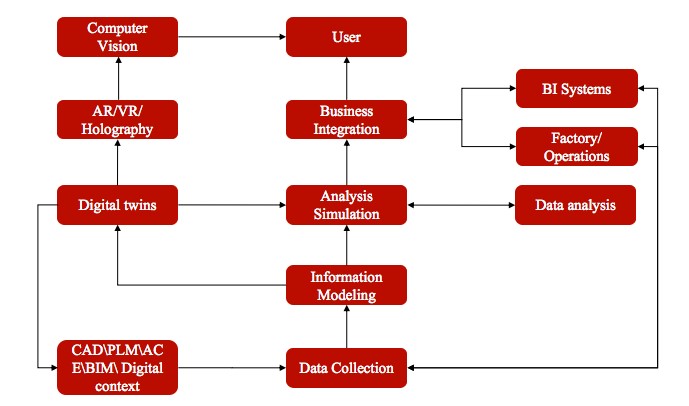

WiMi Hologram Cloud, Inc. (NASDAQ: WIMI) takes the development of a holographic MES intelligent production management system as a starting point, builds an industrial Internet innovation platform based on MES, AI, and holographic technology, further integrates and improves the Internet of Things, machine learning, extensive data analysis, data modeling, and other technologies, enhances the user experience with AR/VR/holographic technology, and supports industrial enterprises to carry out digital transformation in design, manufacturing, service, and management.